Canopy and Rear Window - Section 38

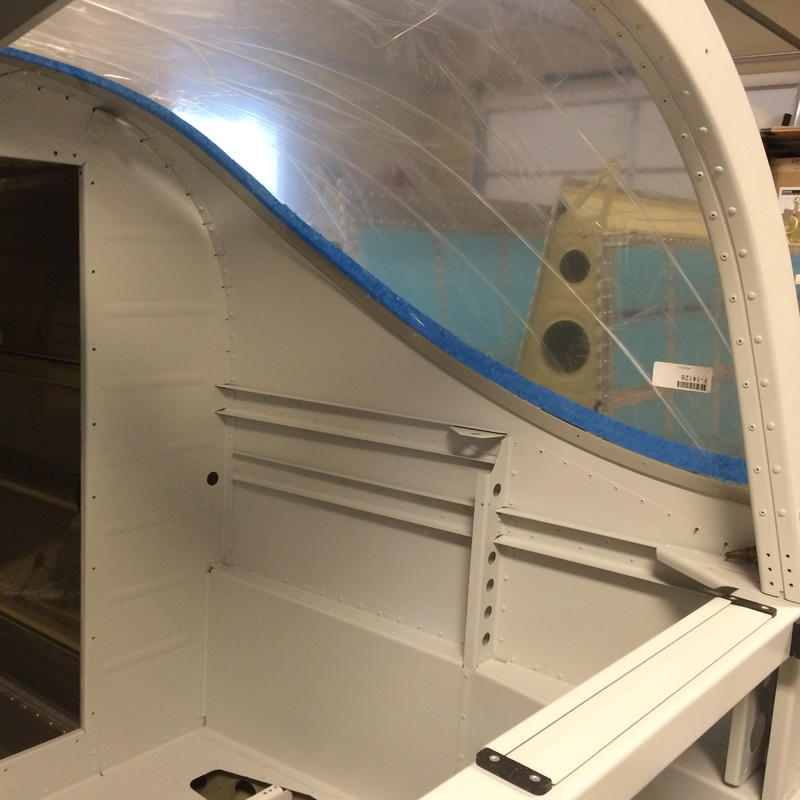

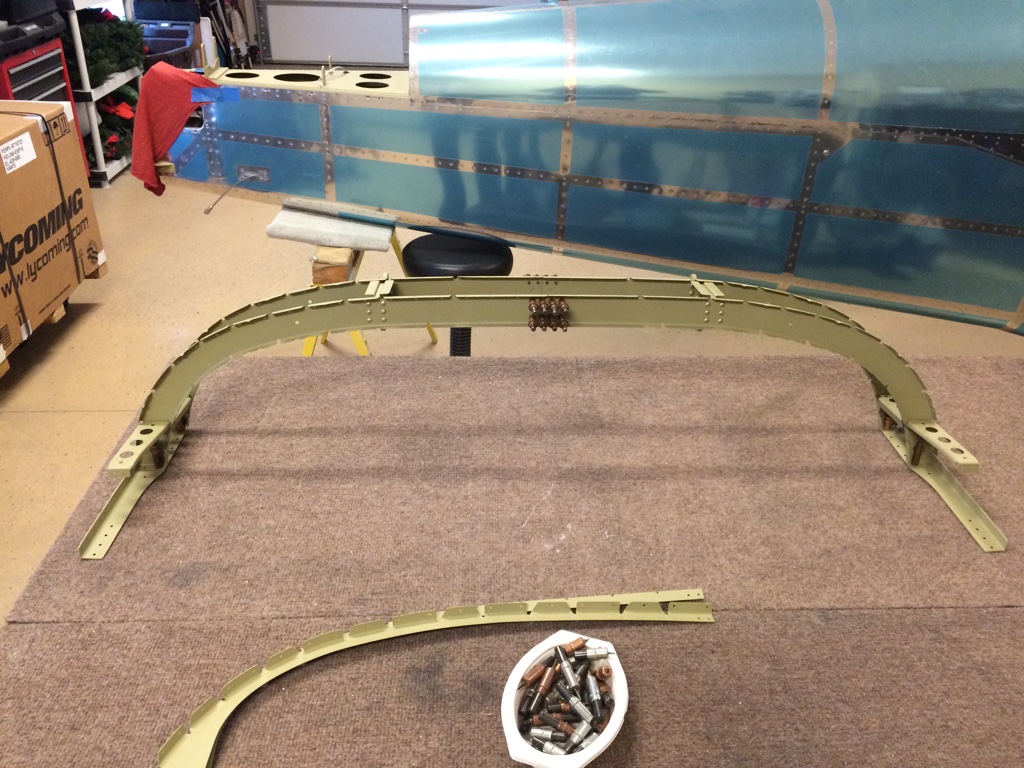

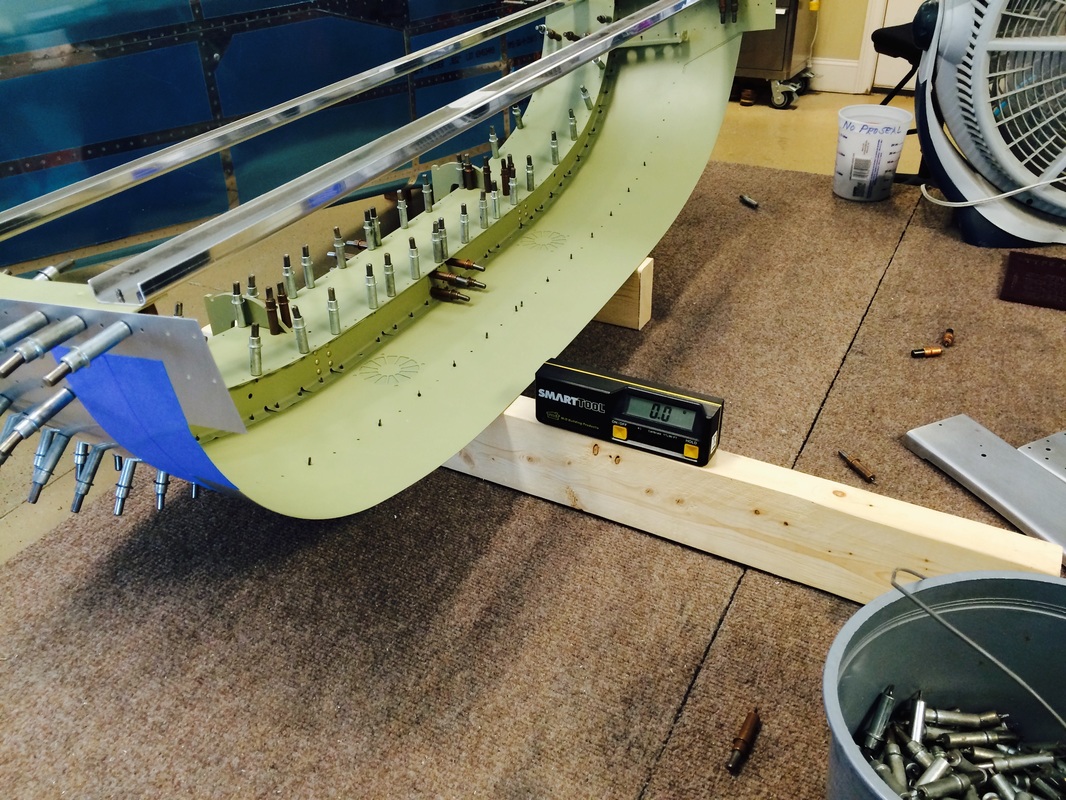

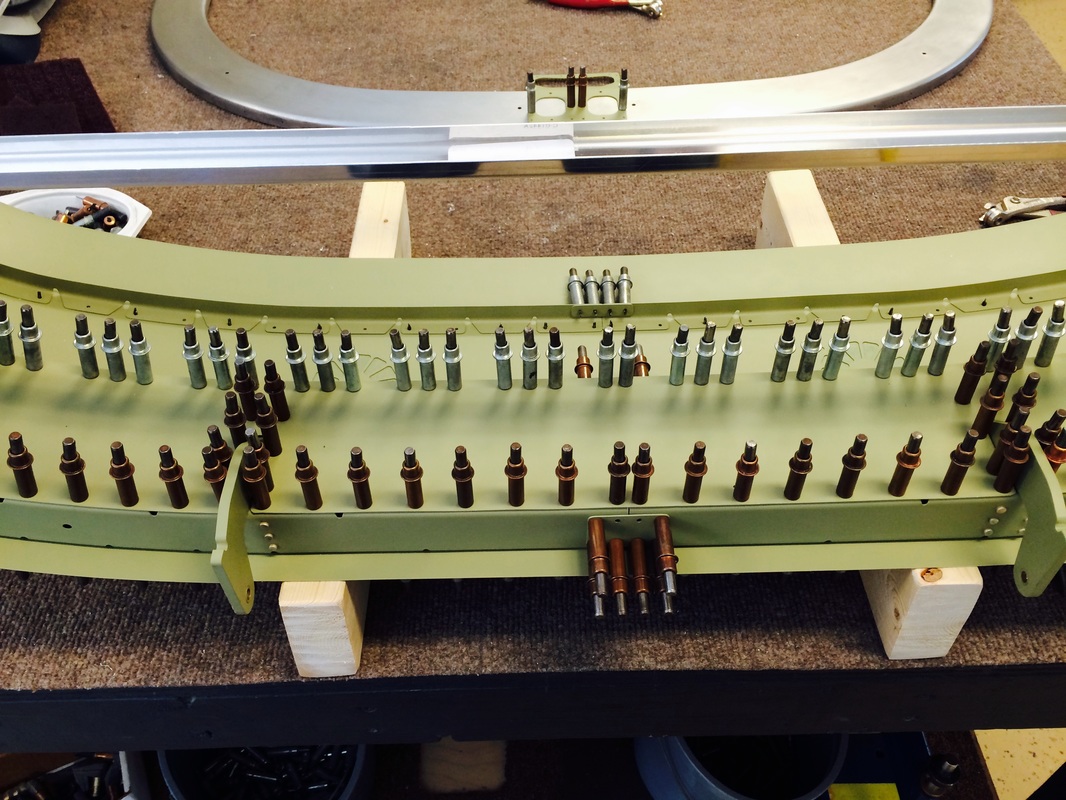

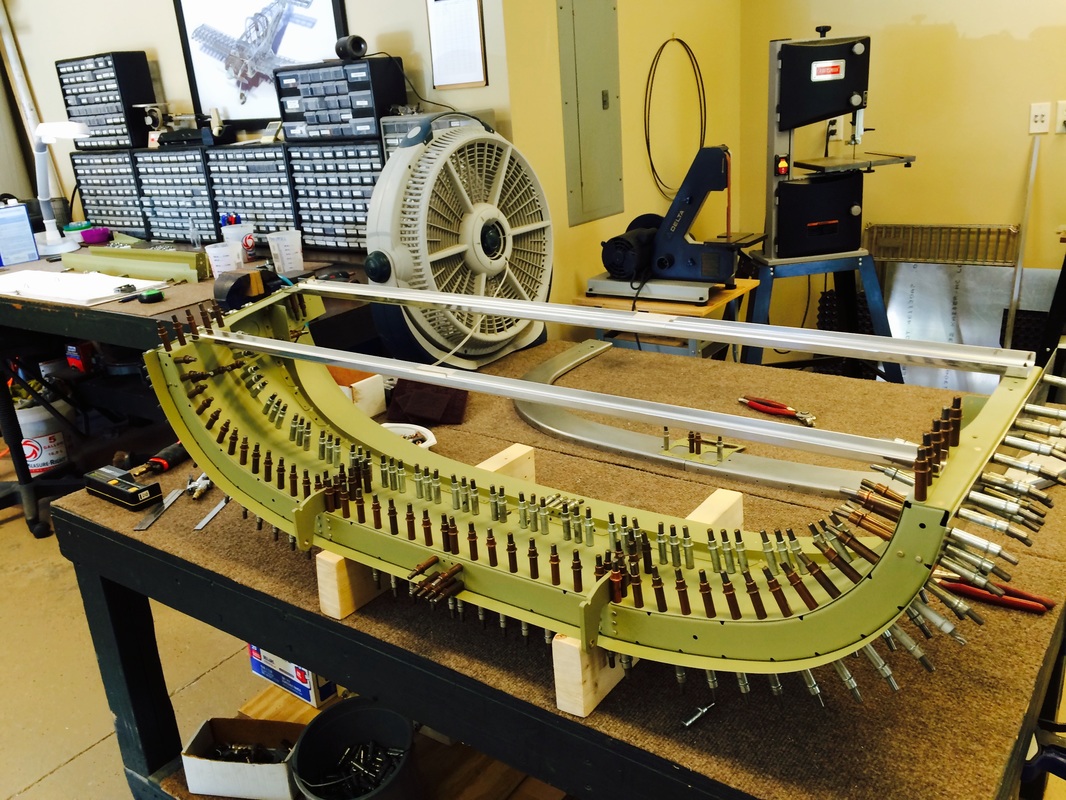

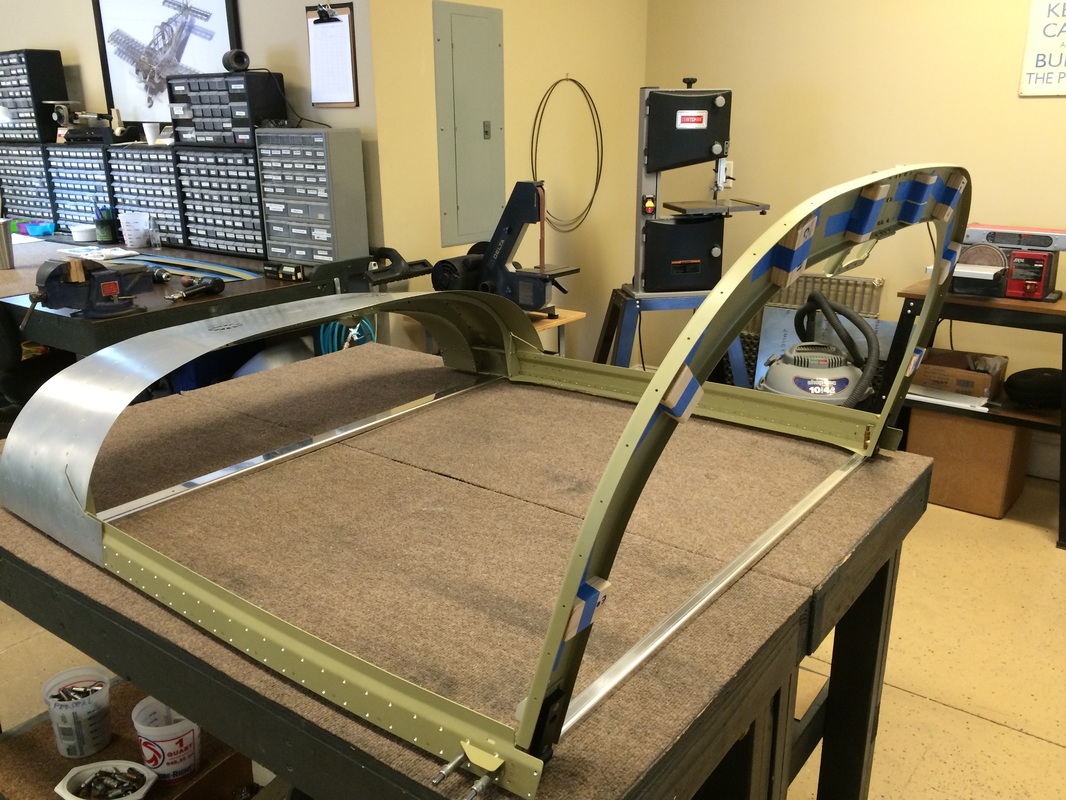

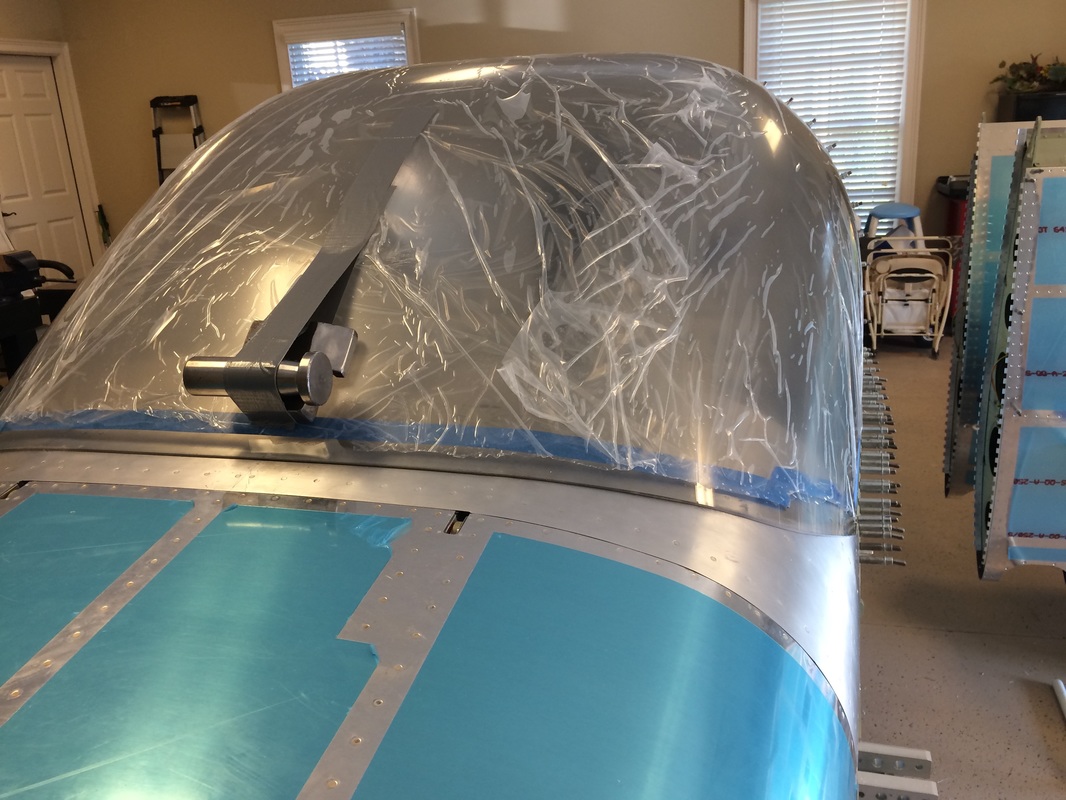

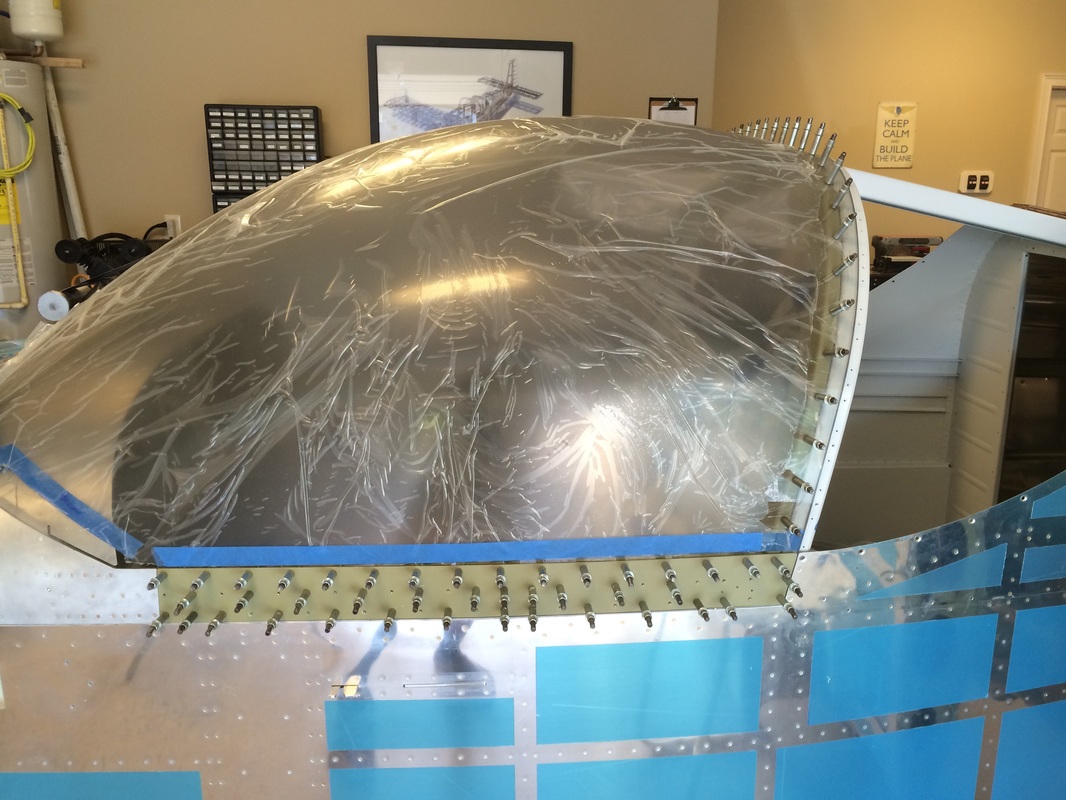

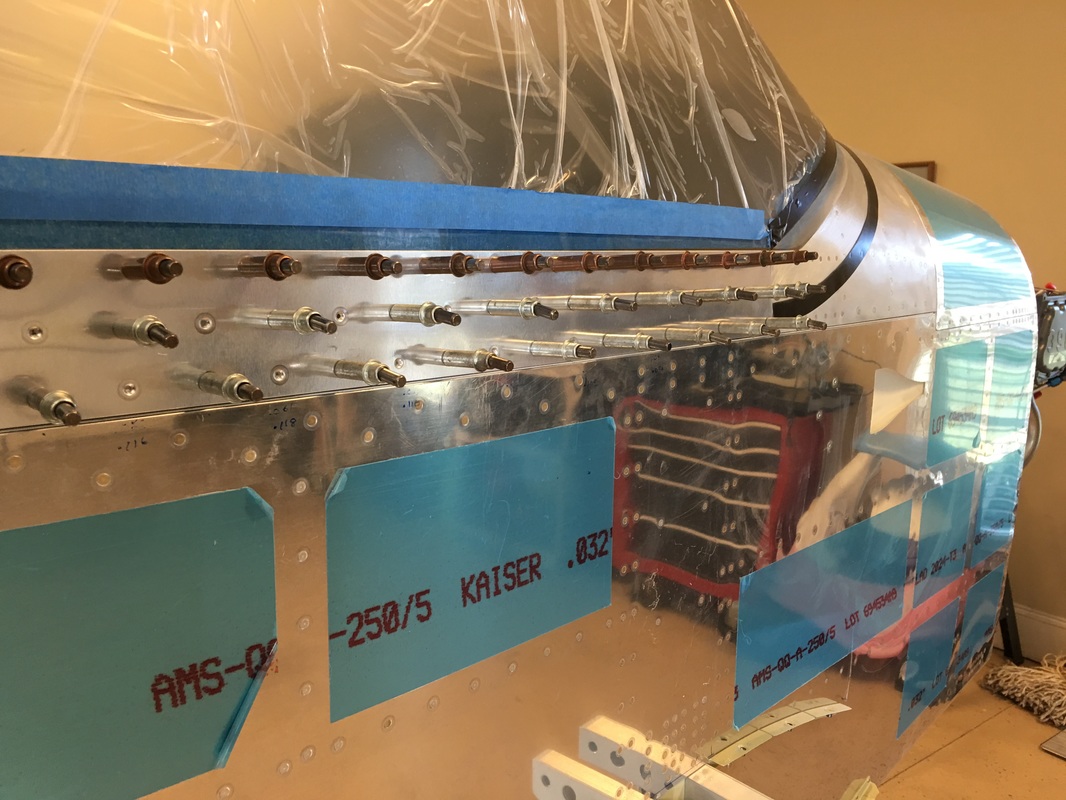

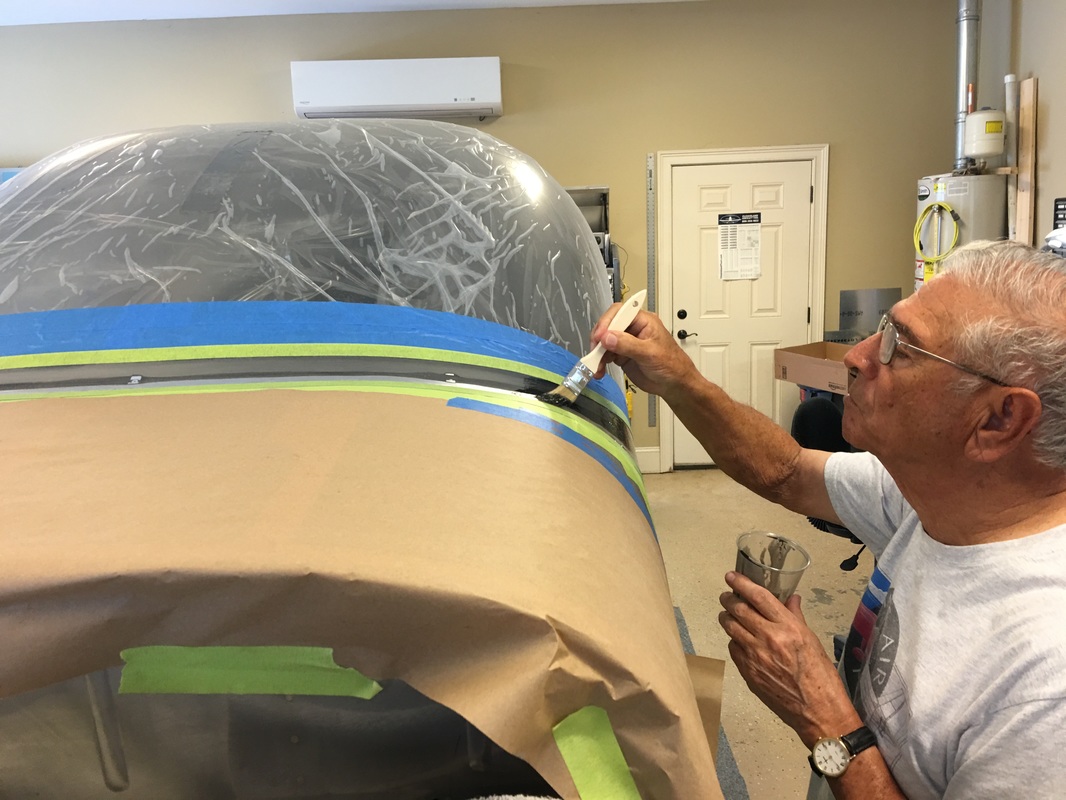

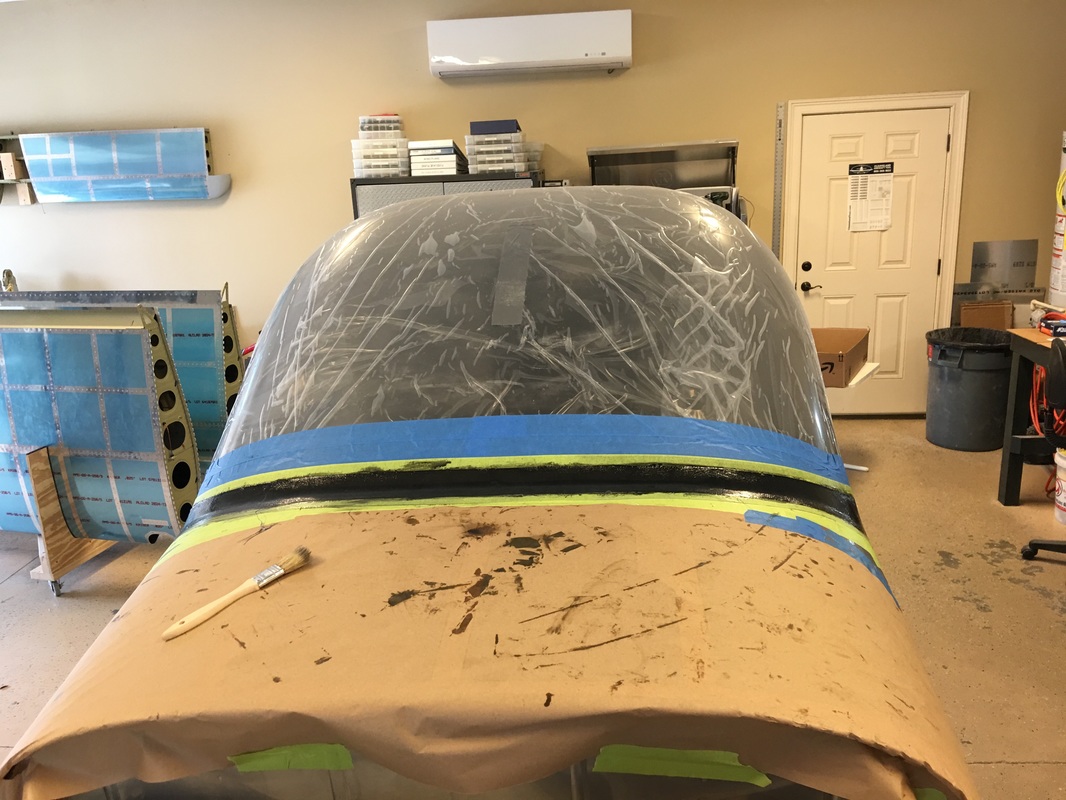

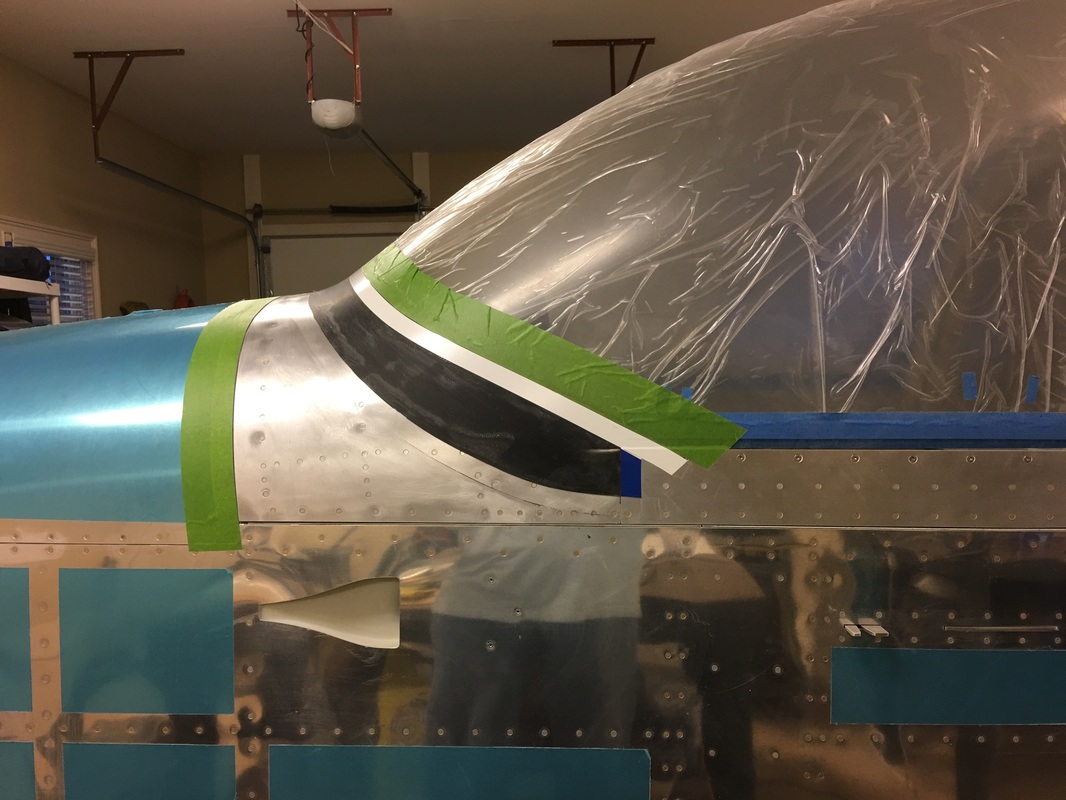

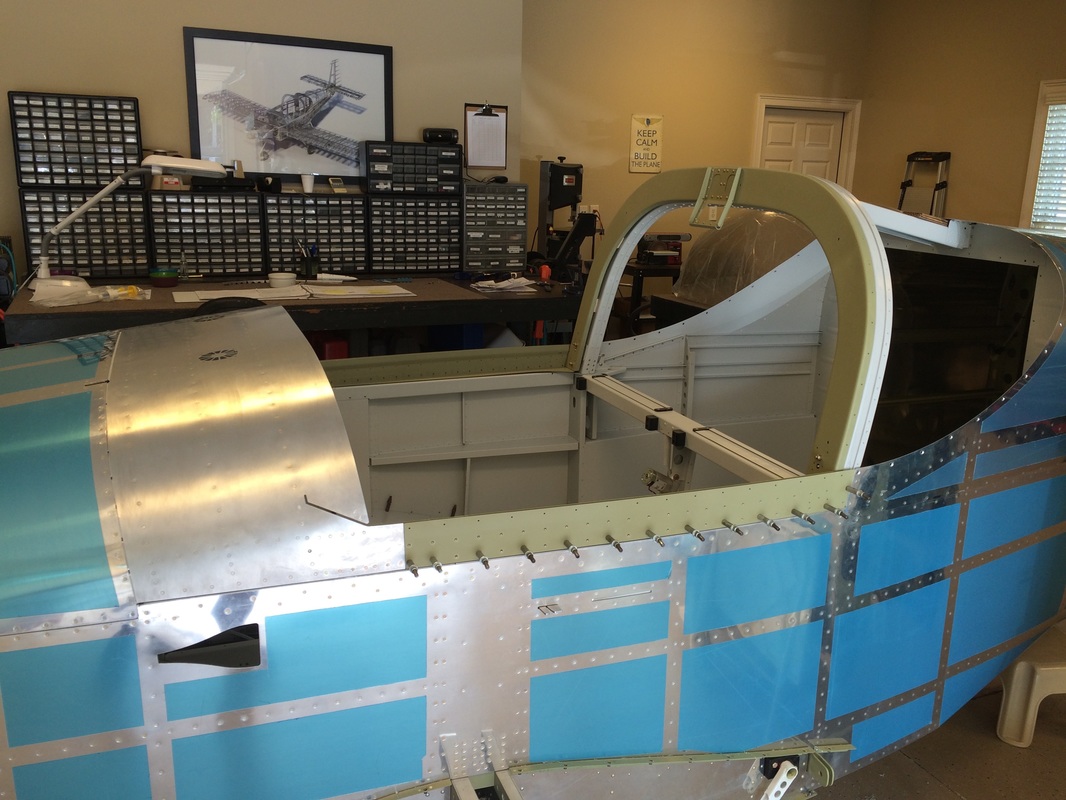

Fitting the frame to the fuselage has been a real challenge. We followed the plans exactly, but the fit was not good aft of the front section. If I had to do it again I would build it on the plane to insure the fit. I will probably remake the canopy side skirts to reduce the visible gap. There is plenty of room for the gasket under the bottom of the assembly.

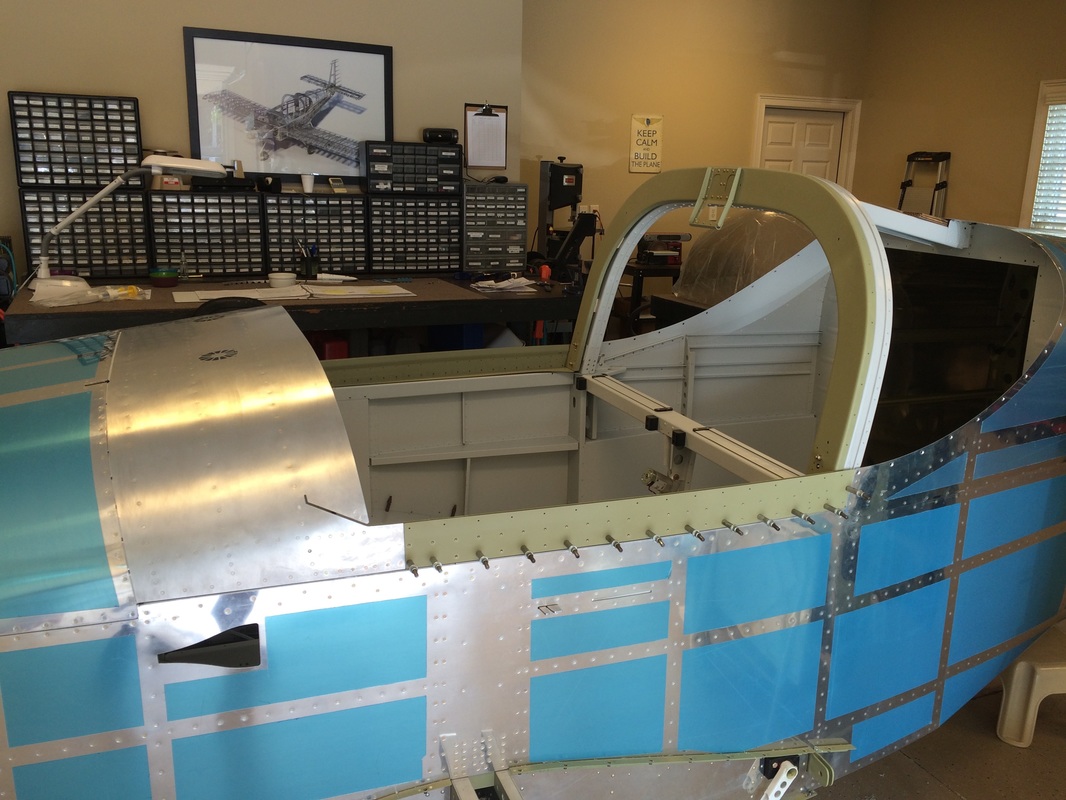

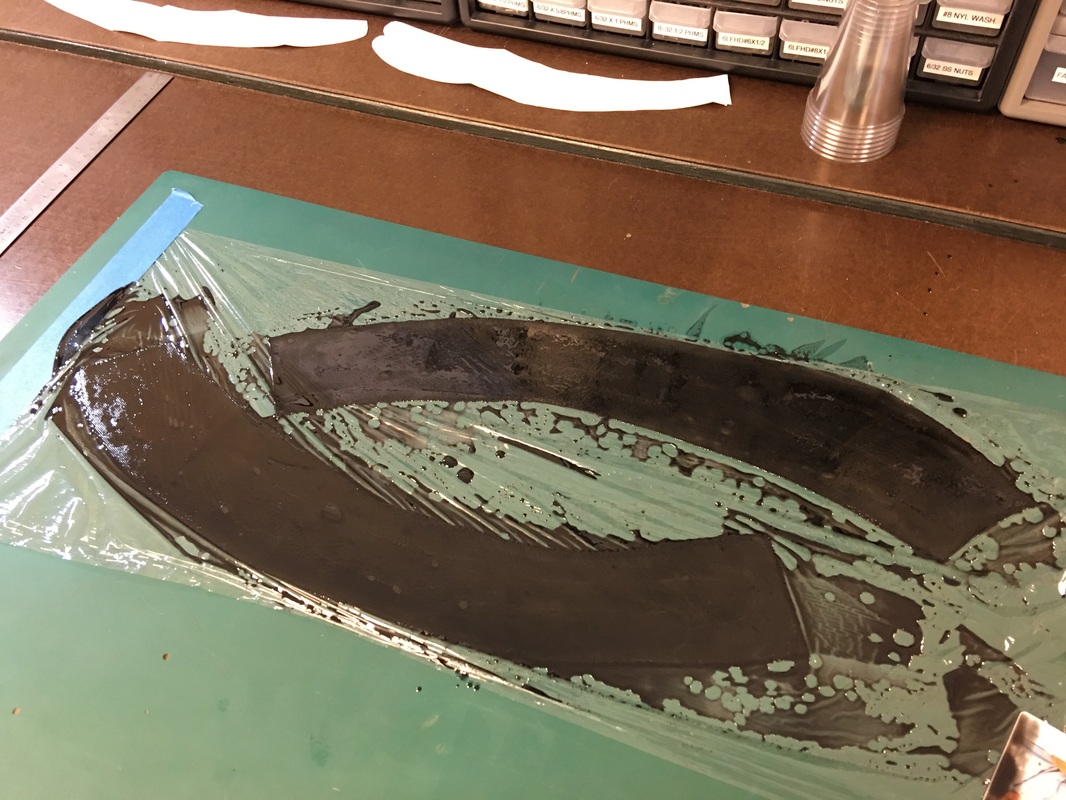

We struggled with the flat/satin paint on the glare shield. The first try for some reason did not adhere well, so I sanded it off and we changed paint, which splattered with the spray gun near the end. It adhered well and we wet sanded and sprayed another coat on and it finally looked good. Painting has not been kind to us on this project. Paints are just not what they used to be because of the changes made to deal with OSHA requirements, I would love to get the old Imron back.

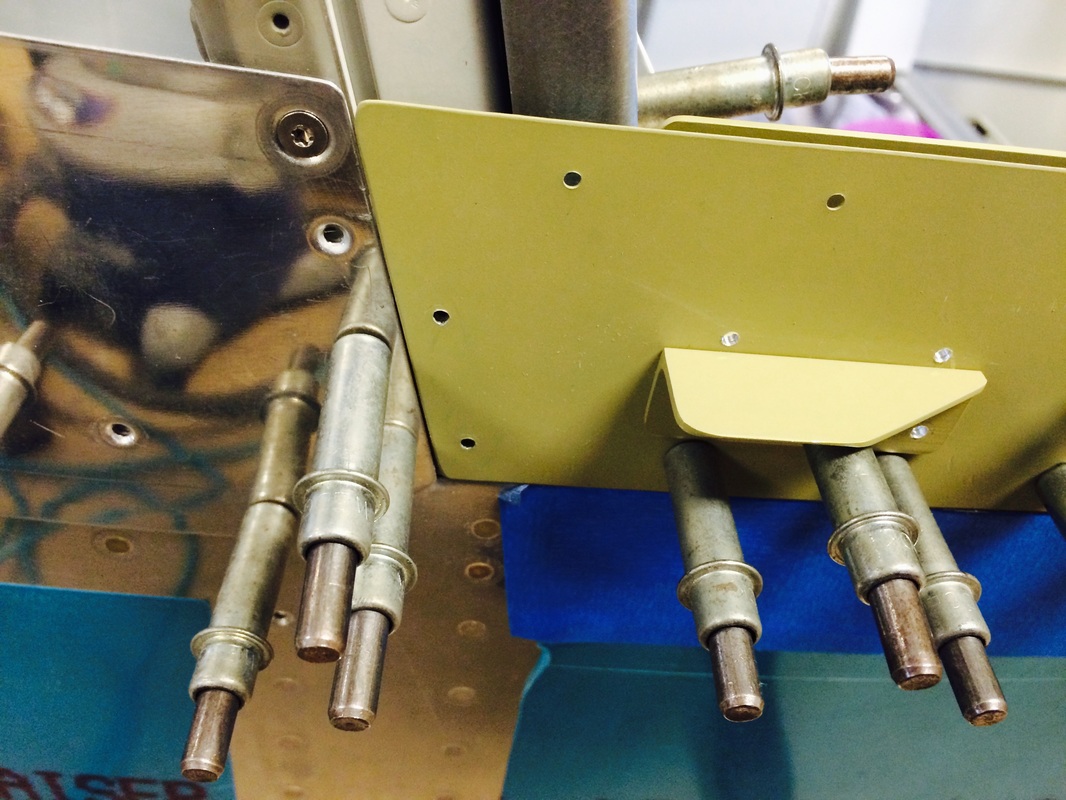

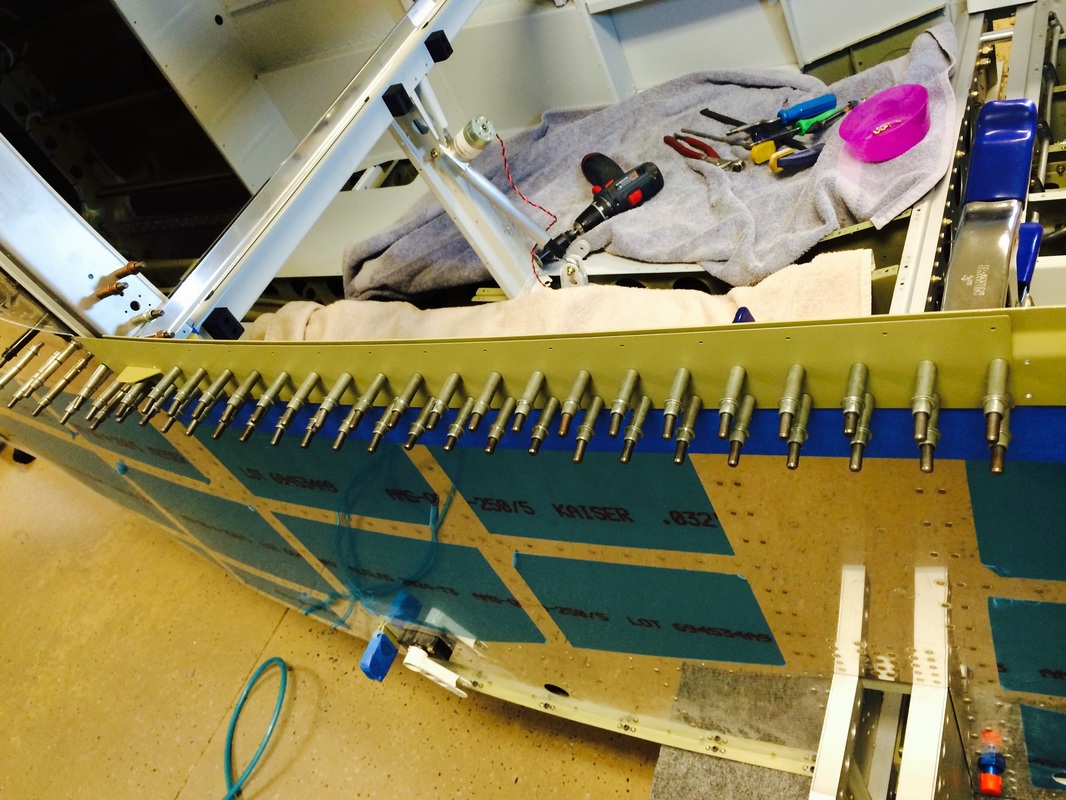

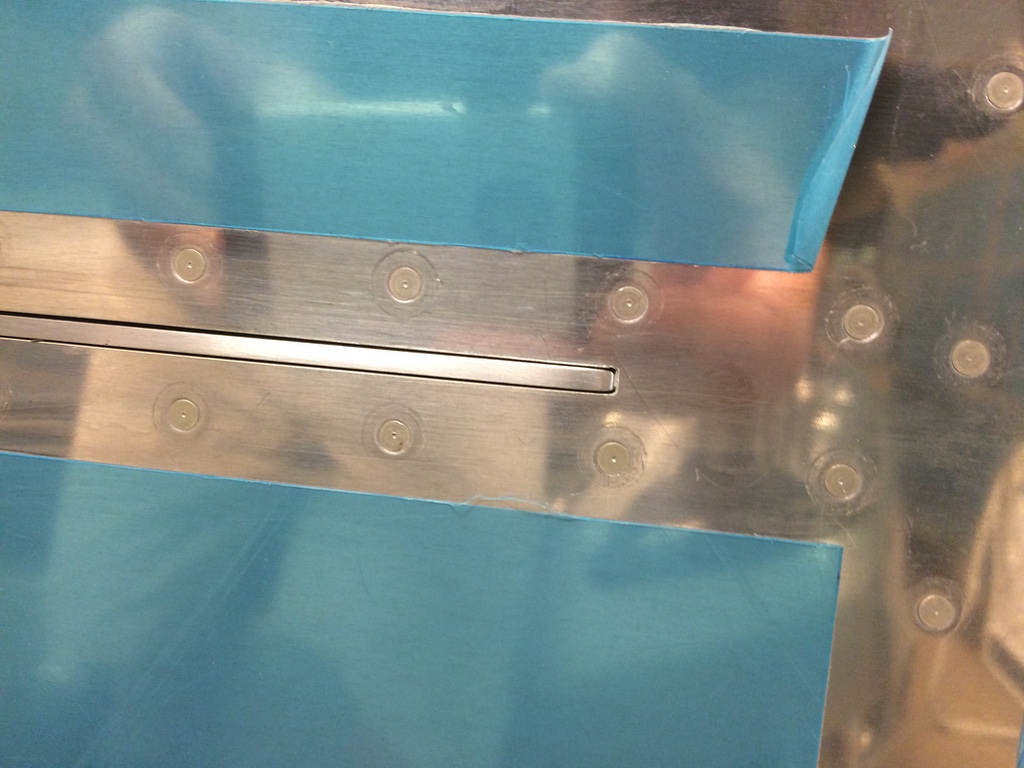

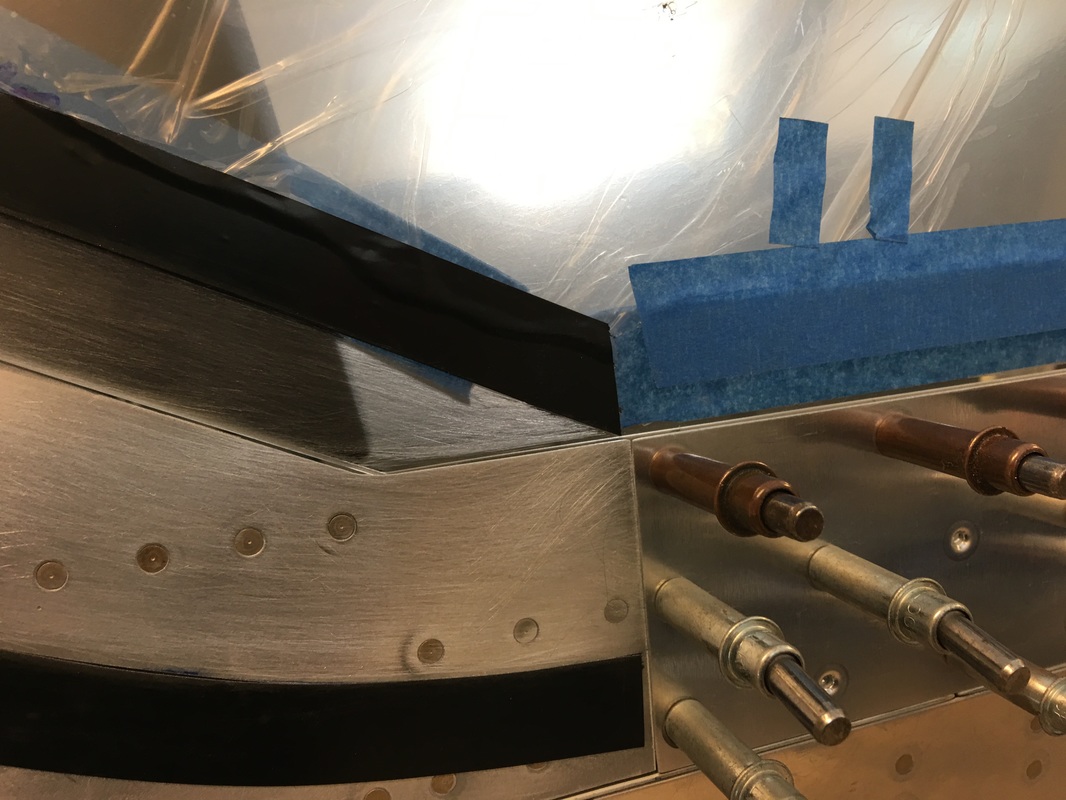

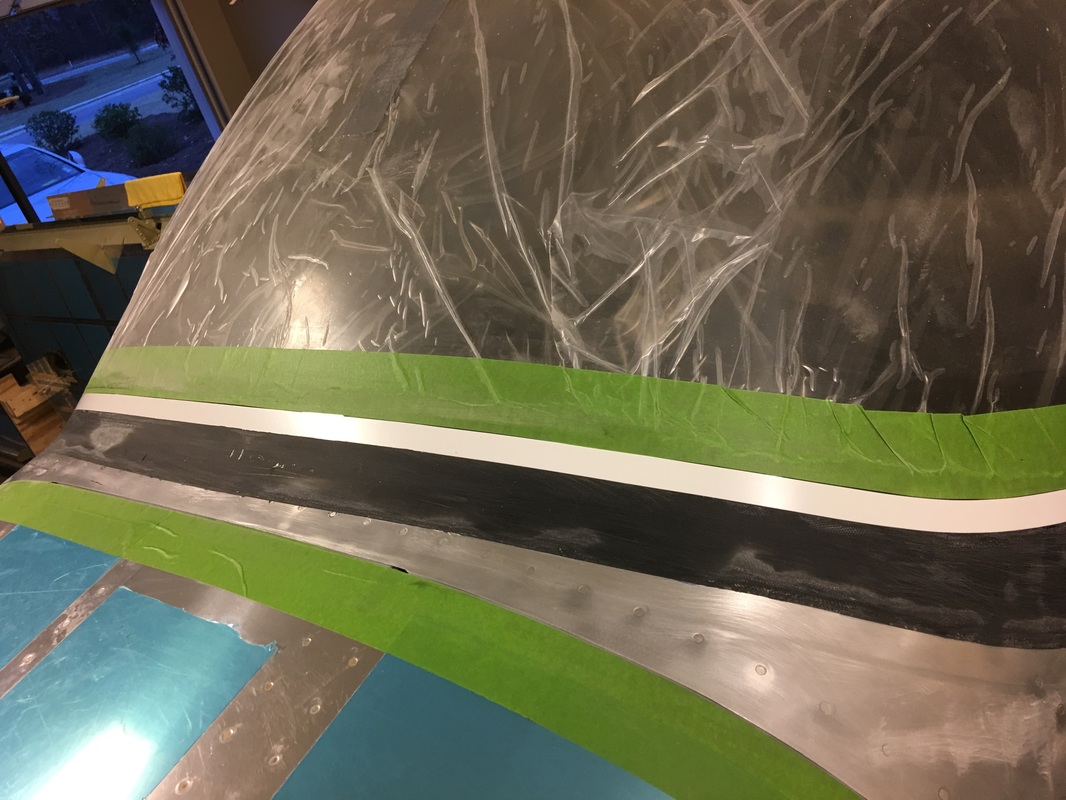

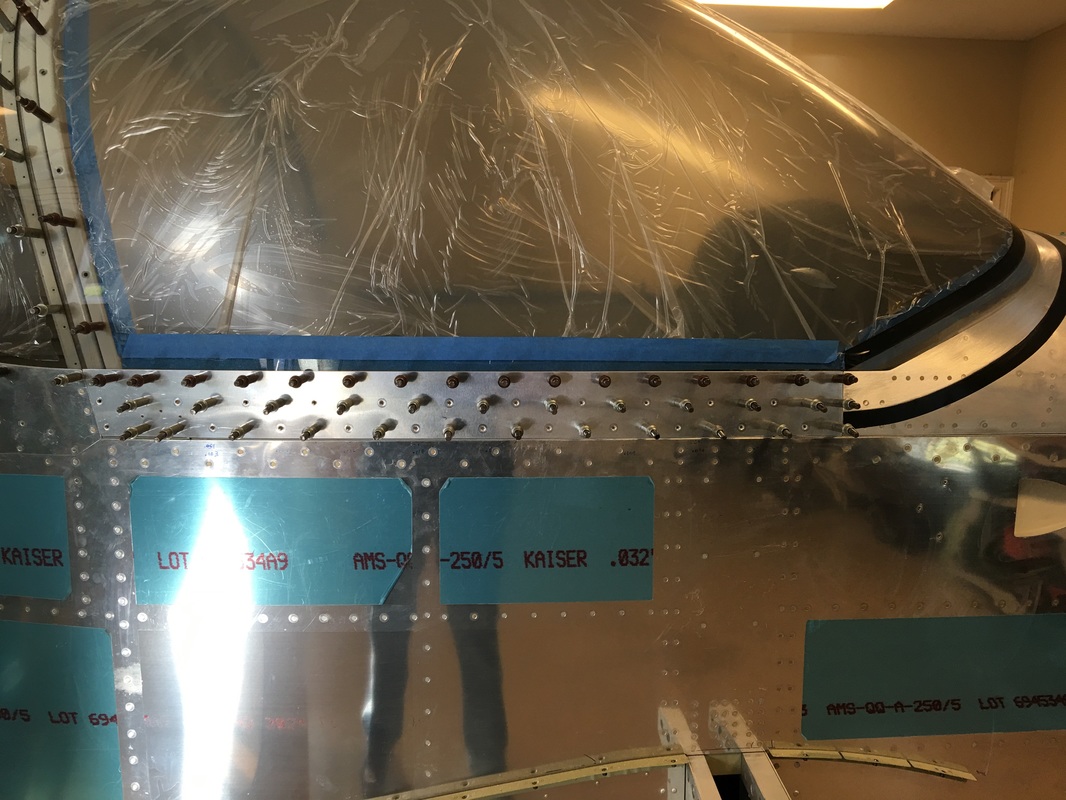

Here you can see the edge of the sill between the canopy skin and the fuselage side skin. I wish they were set back a small amount and the skin then could have butted but I think this will look fine after painting. When I looked at the prototype, there gap was considerably larger, yet looked ok from a distance.

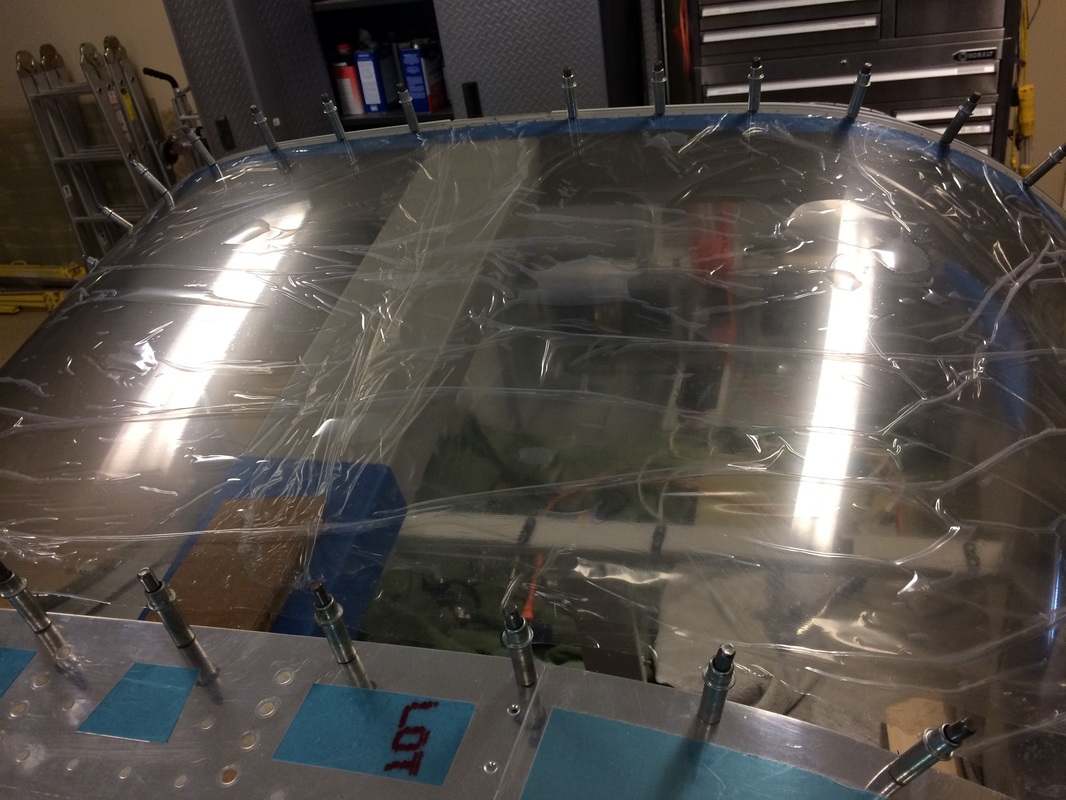

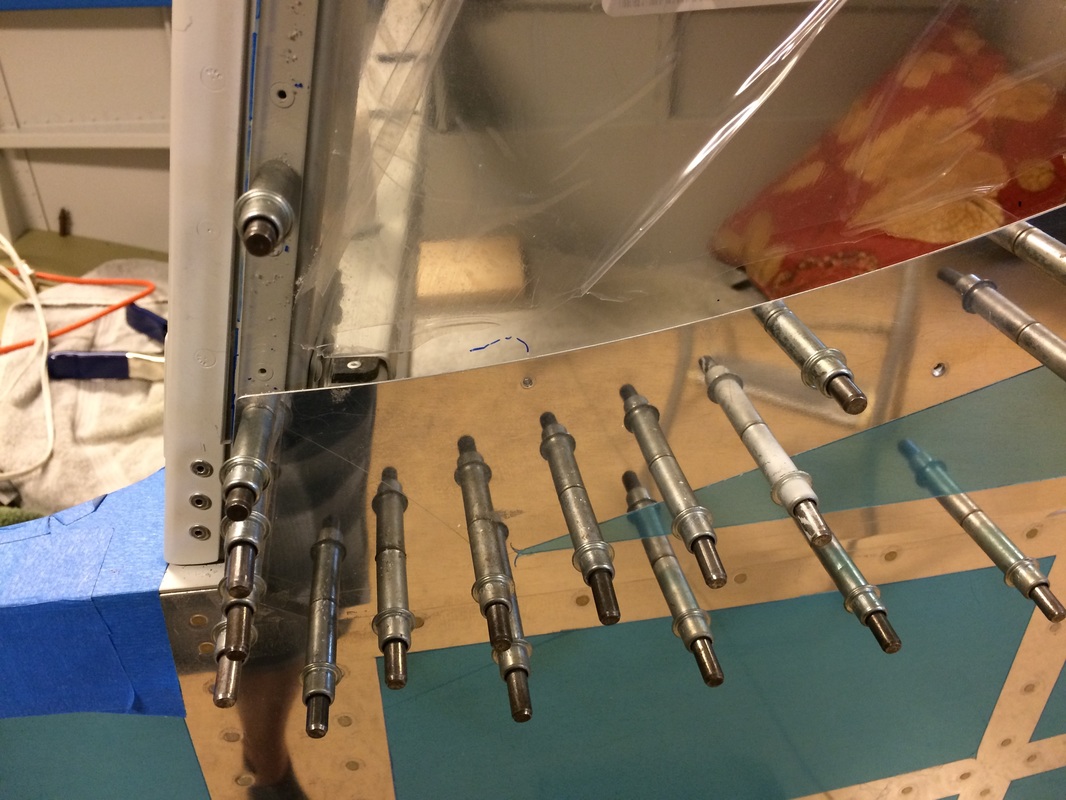

We struggled greatly getting the canopy to fit properly. There is just so many things that need to come together to have it open and close without interference, and yet have a nice appearance at the seams. We finally decided that the best route was to get the canopy frames aligned and function properly with the latches, then get the side skin to fit with minimal gap at the sill. I think if Van's would add a little extra material on these side skins on the bottom, you could then file it back to match as required.