Flaps - Section 21

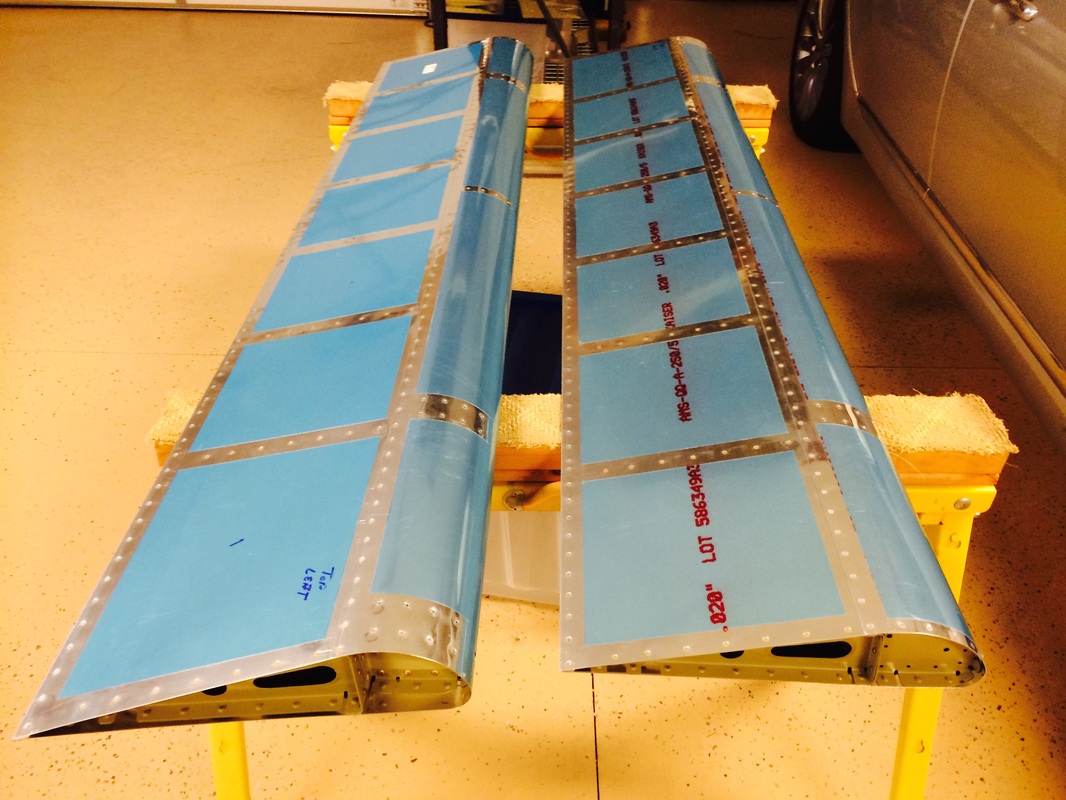

Vans new slotted flap design

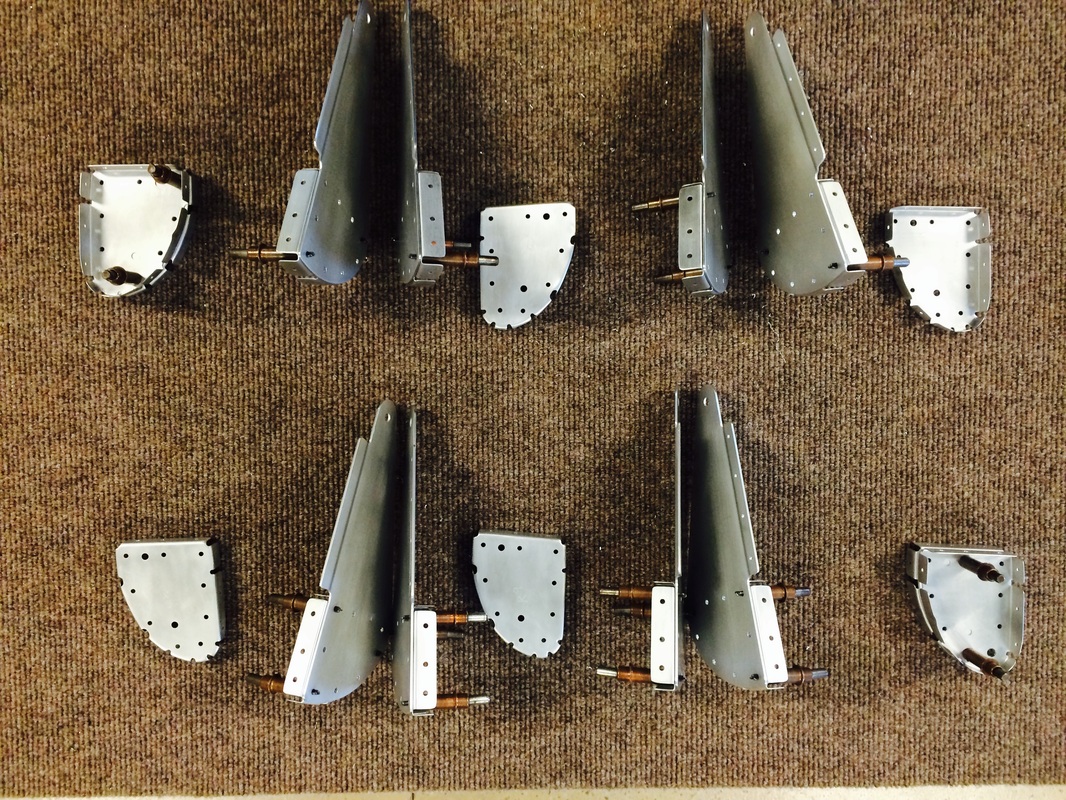

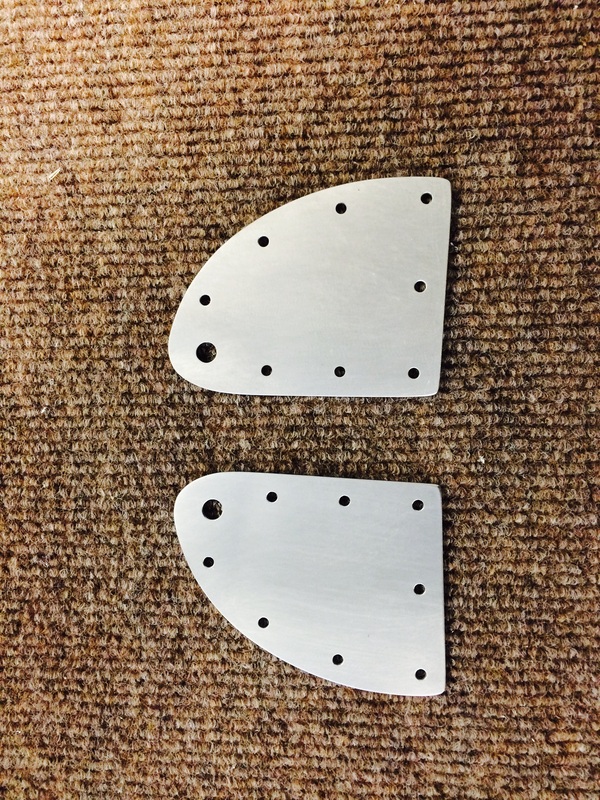

Vans supplies 4 these doublers with 3/32 holes near the large holes for plate nuts, but I ended up countersinking all 4 in error. So rather the replacing the 2 that did not get plate nuts with more holes that are not required, I made up new ones without them. So now the rod end bearings will not be over the 3/32 holes. Does it matter, probably not, but it has to be better with no holes if they aren't needed, right?

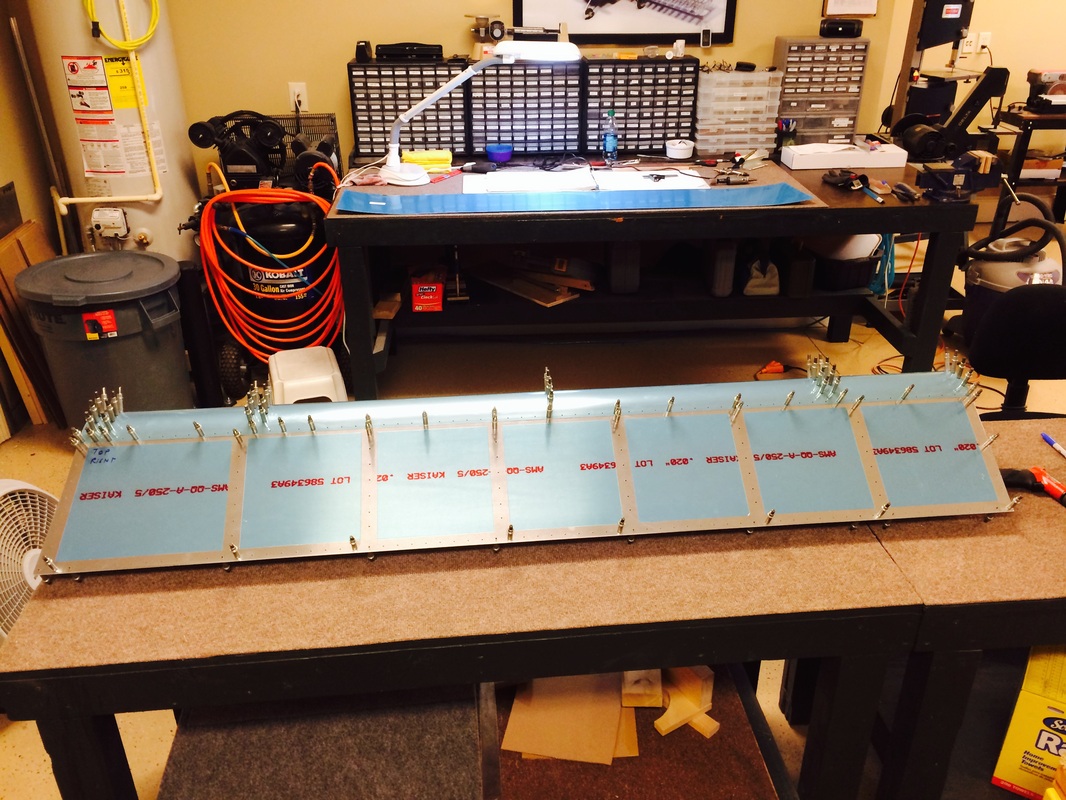

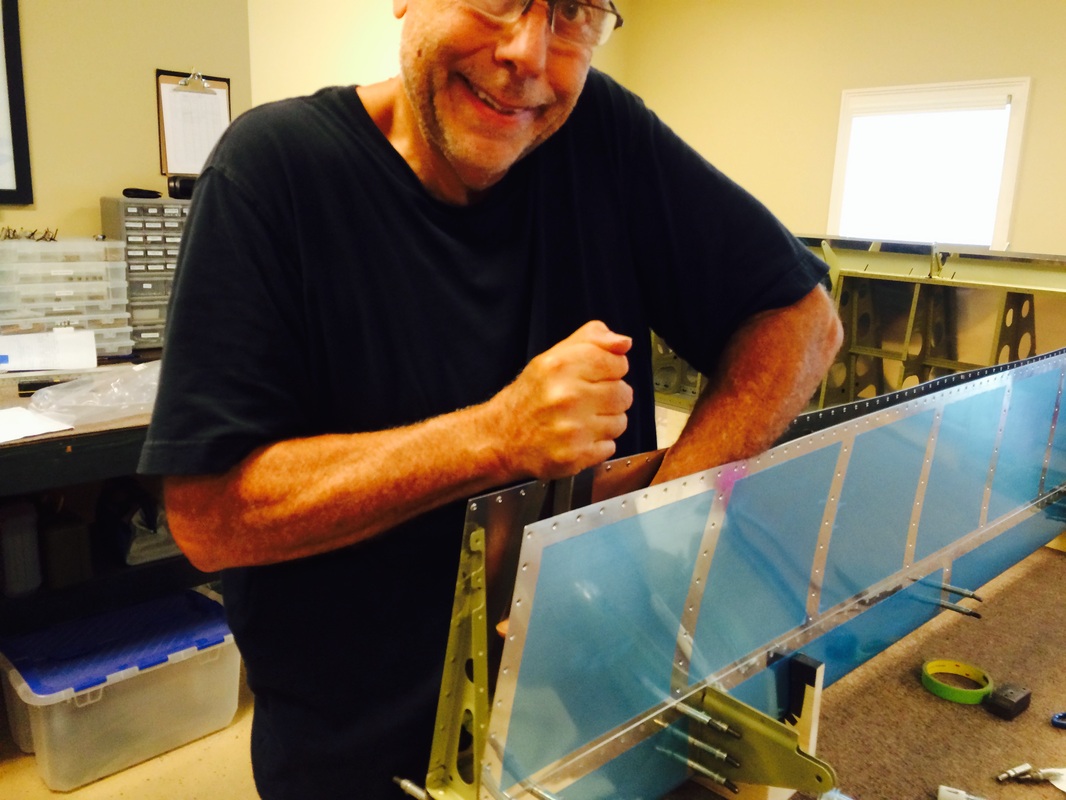

Leading edge is on and match drilled to the ribs. It fit ok, but the rib front edge does not quite touch. This is kind of funny since the plans make a point to buff them round to keep the skin smooth. The holes for the spar are already punched, so you really have no control over the fit of the ribs. Hmmmm.

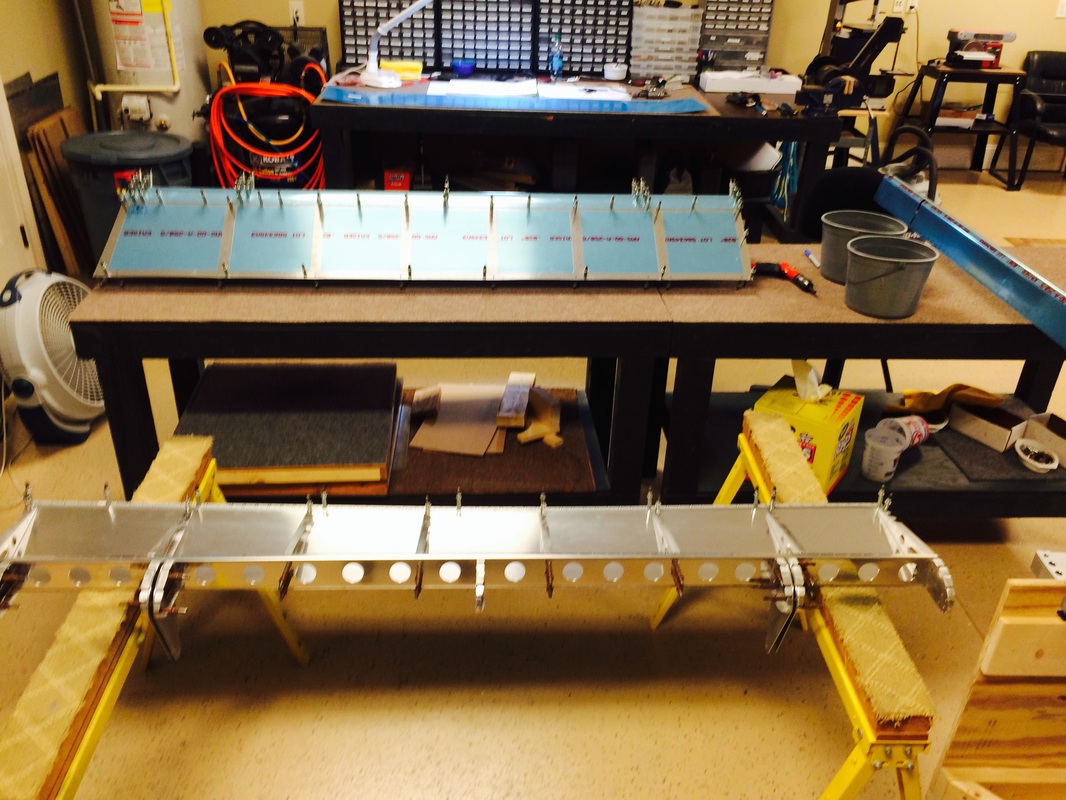

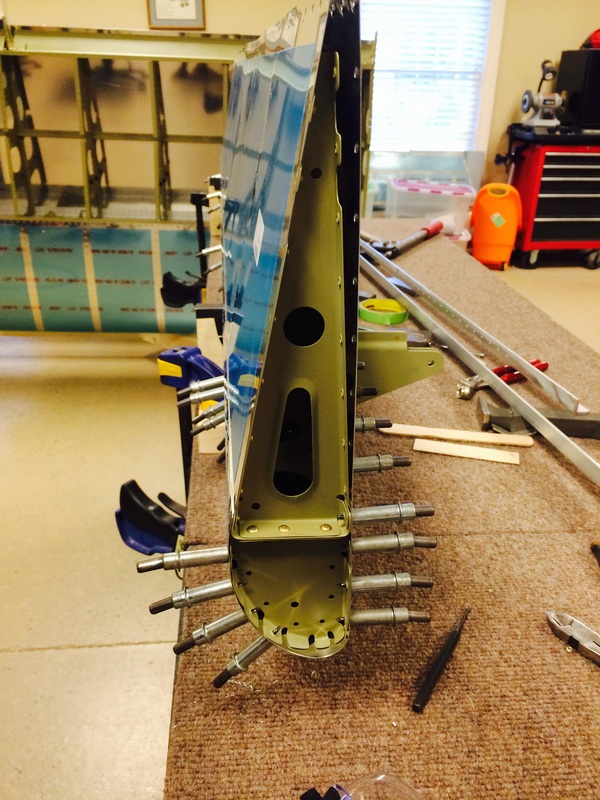

This is riveting the bottom skin the the spar. Not much room, so we used the 12" long bucking bar we bought for riveting the elevator spar. This worked well except for the rib locations. There I used a 1" x 1" x 2" bucking bar we made up with a slightly slanted face to match the spar angle which is about 10 or 11 degrees.

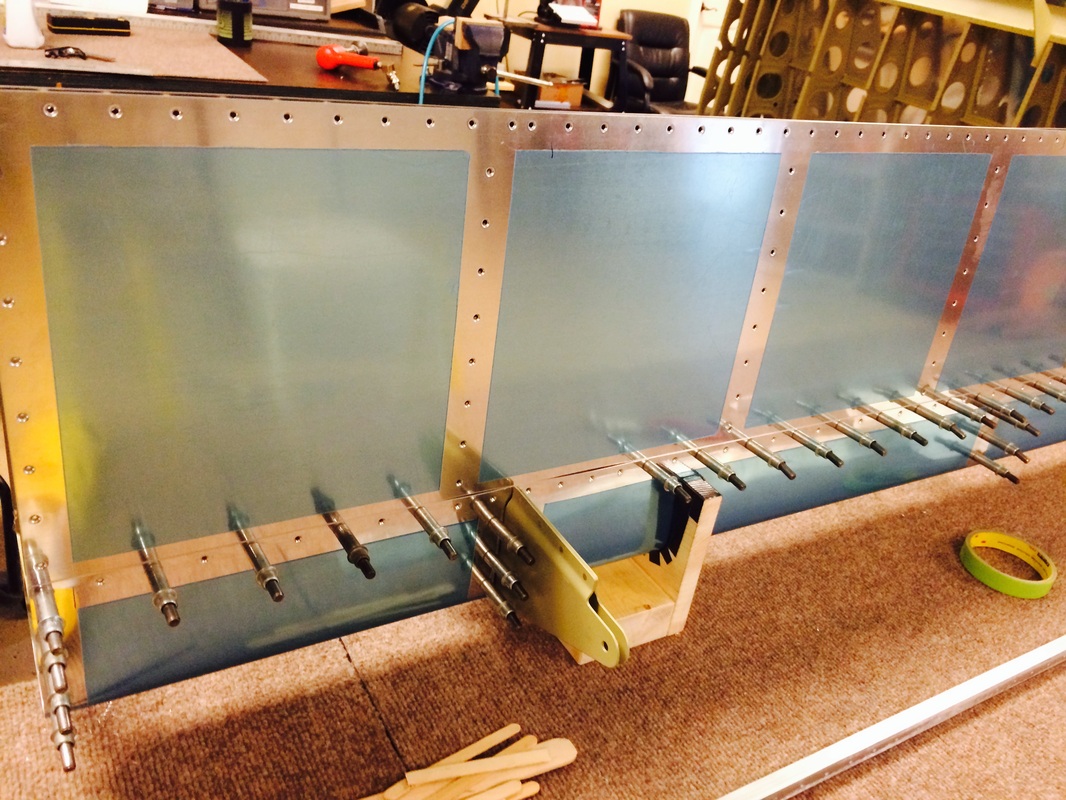

Flap trailing edges were done with the VHB tape on the flaps rather then JB Weld. It really did not work that well. It seemed the adhesive was too thin the adhere to the V wedge. Since VHB is all adhesive with no backing, I may try 2 layers on the ailerons and see if that works better. That being said, I squeezed the trailing edge slowly alternating from the middle out and finished with the 10-11 degree head in the hand squeezer. The results were OK and the trailing edge is straight within a 1-2mm.