Fiberglass & Body Work

For the next month we will be doing nothing but body work on N947RV. The process that I used on the RV 7A was time consuming and required a huge amount of elbow grease. We have decided to copy Van's method using Poly-Fiber UV smooth prime. The procedure goes like this:

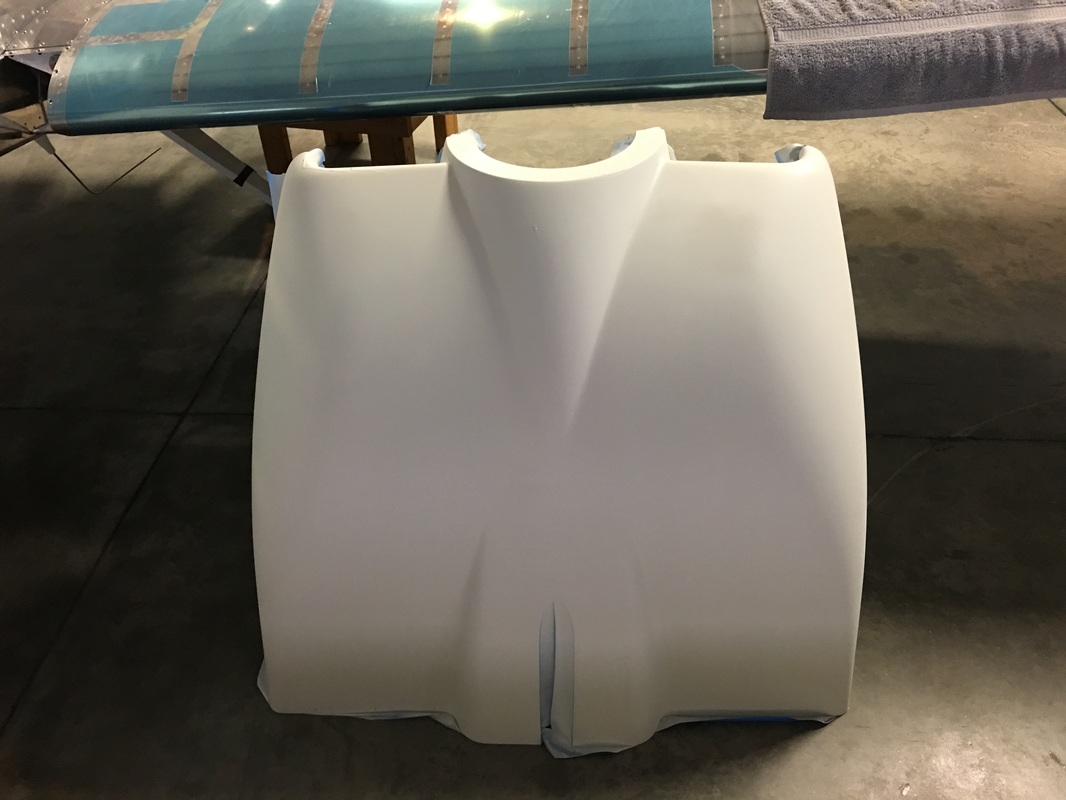

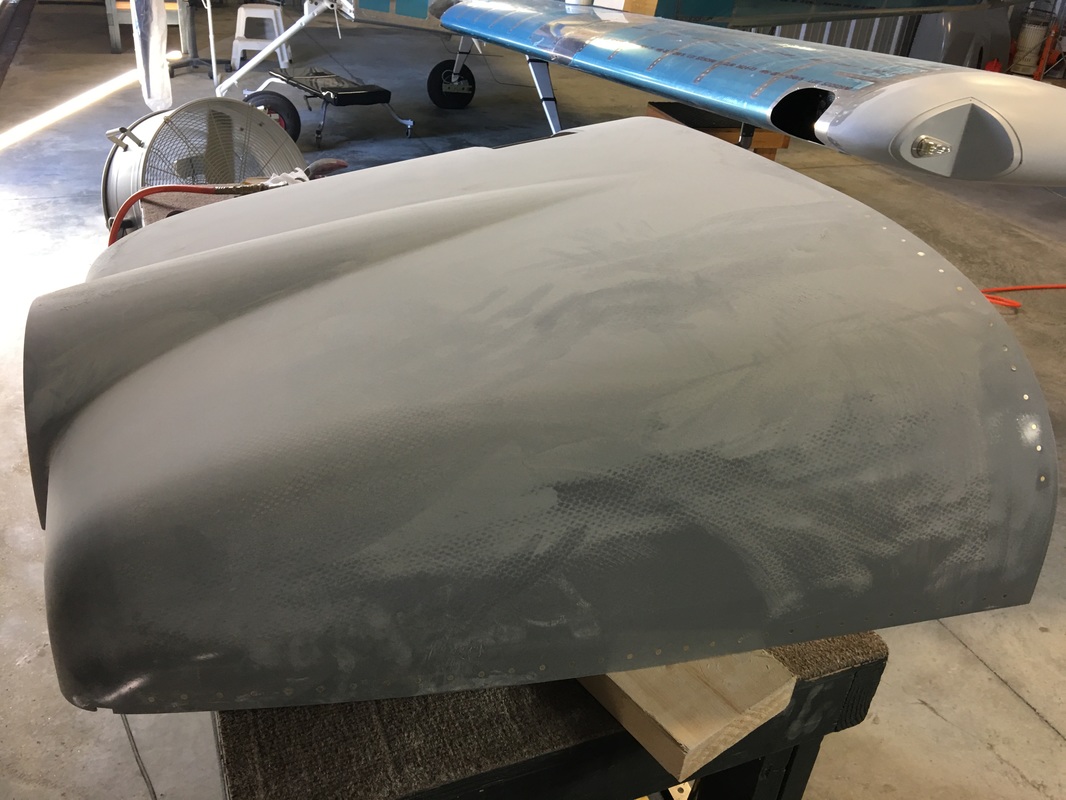

1 - Sand the glossy surface with 120 grit so the smooth prime will stick and expose the main pin holes. Also, with the cowl this helps to reduce the coats required to cover the basket weave pattern.

2 - Squeegee on the first coat of smooth prime to force it into the pin holes. This is supposed to be pin hole killer, we shall see.

3 - Using a foam roller, lay on a few more coats of smooth prime and sand smooth. Then repeat except spay on 3 coats on more if needed until you are sure everything is smooth and the pin holes are filled.

4 - Spray on a good two part filler/sealer primer. We are using PPG K36 Acrylic Urethane Primer Surfacer. I used this on the RV 7A without any real issues. They say you can spray it without thinning, but even with a large tip, I needed to thin it about 5-10%

I'm not going to go into great detail on this process, but will show you the process with comments. This is the part of the build that most people abhor and I'm no different. You can get your painter to do all this, but the up charge is significant and they don't like to do it either. Some recruit body workers to get it done, I think the is the cowardly way to do it.

1 - Sand the glossy surface with 120 grit so the smooth prime will stick and expose the main pin holes. Also, with the cowl this helps to reduce the coats required to cover the basket weave pattern.

2 - Squeegee on the first coat of smooth prime to force it into the pin holes. This is supposed to be pin hole killer, we shall see.

3 - Using a foam roller, lay on a few more coats of smooth prime and sand smooth. Then repeat except spay on 3 coats on more if needed until you are sure everything is smooth and the pin holes are filled.

4 - Spray on a good two part filler/sealer primer. We are using PPG K36 Acrylic Urethane Primer Surfacer. I used this on the RV 7A without any real issues. They say you can spray it without thinning, but even with a large tip, I needed to thin it about 5-10%

I'm not going to go into great detail on this process, but will show you the process with comments. This is the part of the build that most people abhor and I'm no different. You can get your painter to do all this, but the up charge is significant and they don't like to do it either. Some recruit body workers to get it done, I think the is the cowardly way to do it.

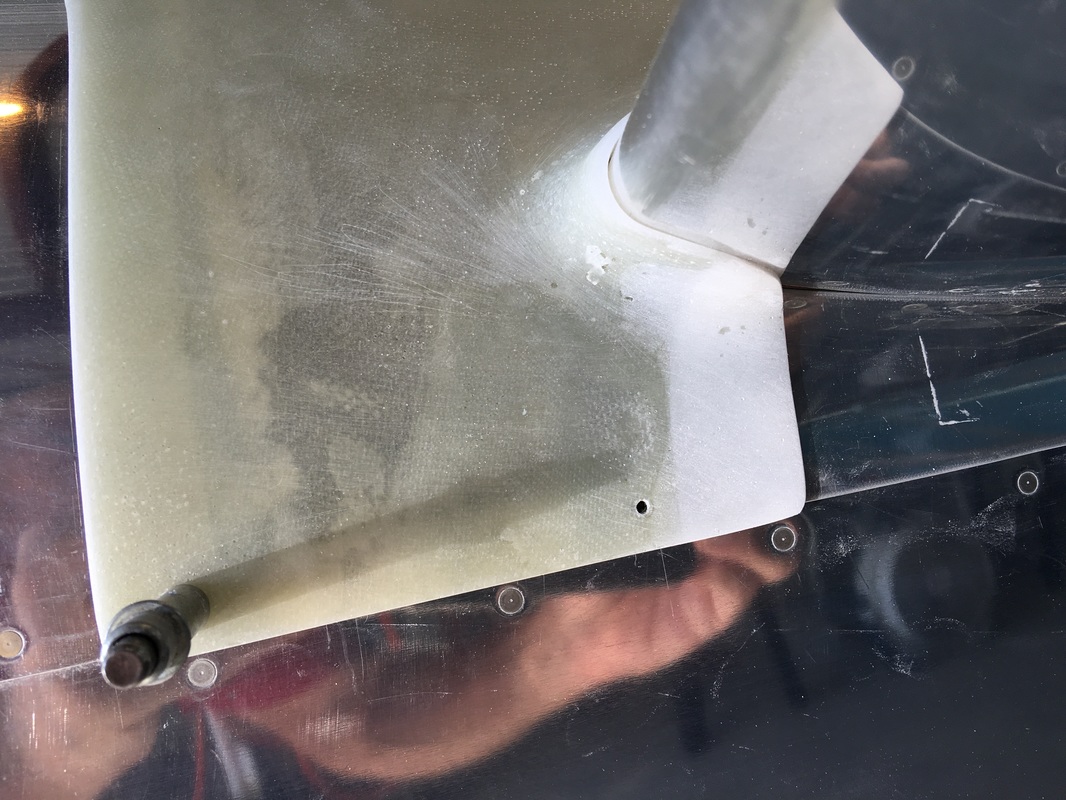

Beginning of the sanding and filling process. Here you can see the weave, but with just a little bit of sanding with 120 grit the weave starts to fade. I am just trying to sand enough to get the smooth prime a surface to stick to. Do not try to get ride of the weave buy sanding it away. You will weaken the cowl and make the job so much worse.

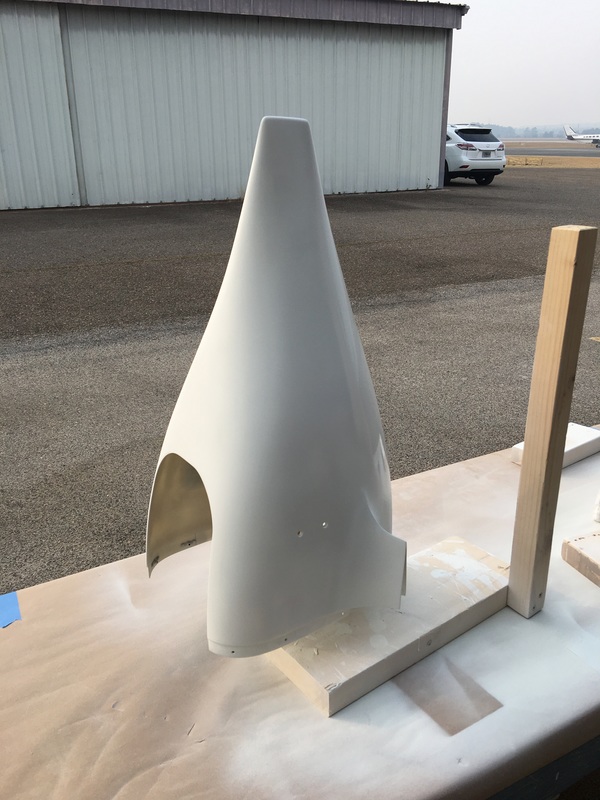

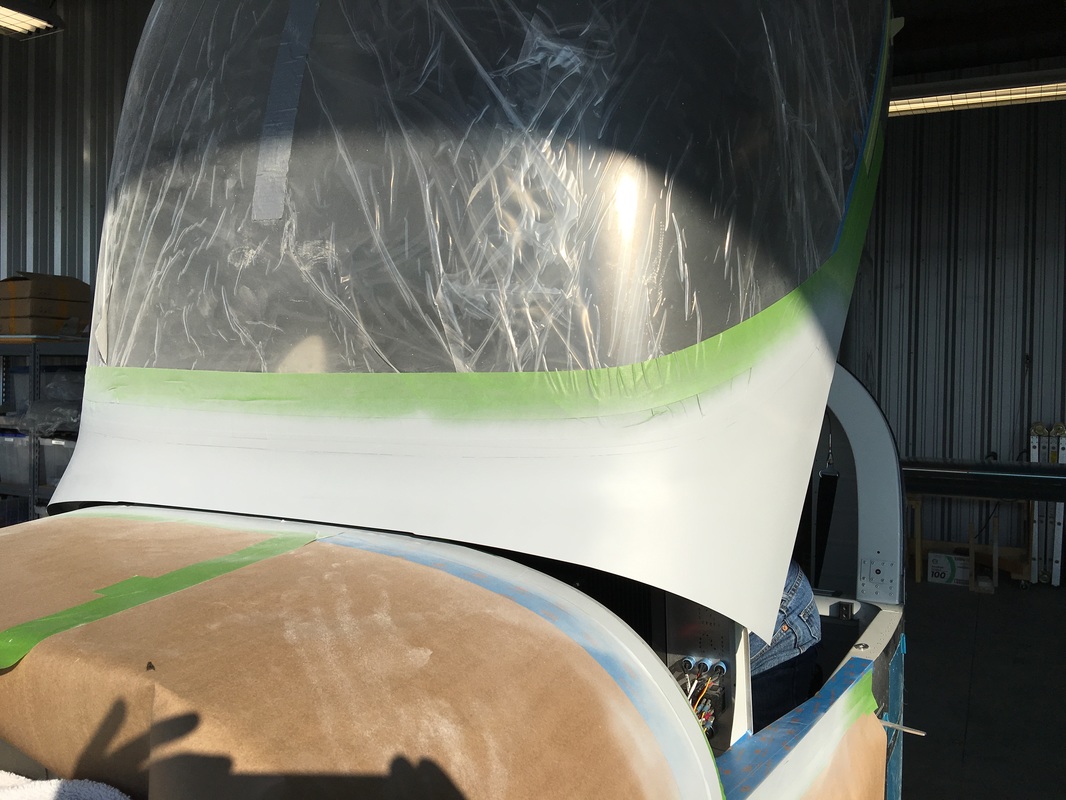

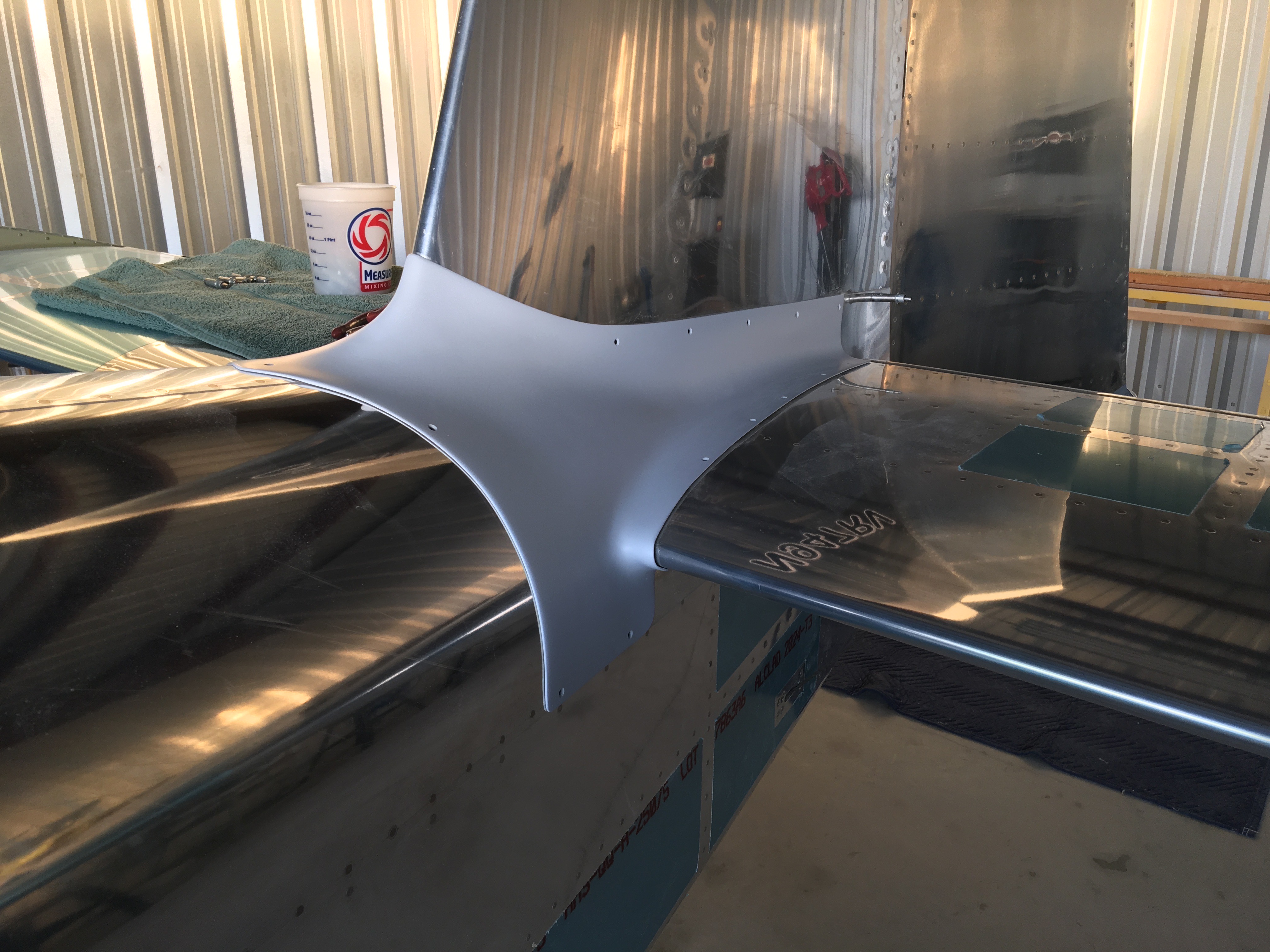

I decided I wanted to extend the bottom of the empennage faring to go fully over the the aluminum aft faring, the one furnished didn't quite get there. I covered the fuselage and stabilizer with clear packaging tape, waxed it, put in 3 layers of 9 once glass cloth and then a mixture of epoxy and flox.

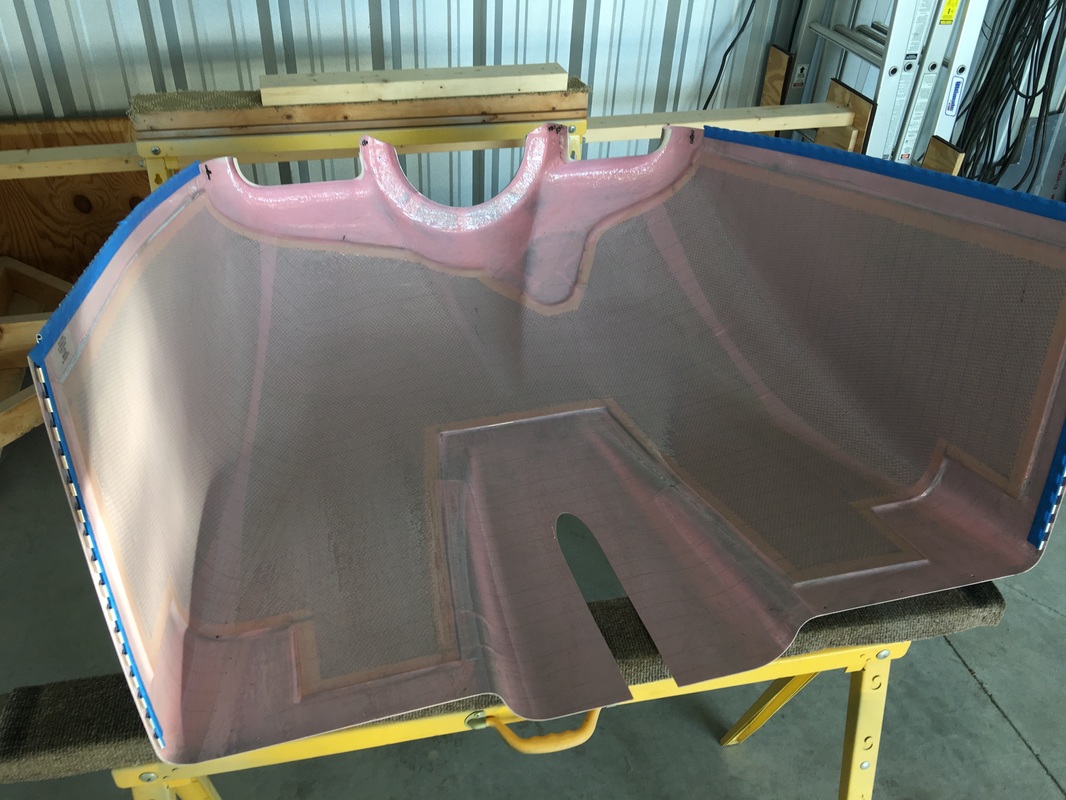

Per Vans plans, we scuffed up the inside of the cowl and brushed on a coat of west epoxy. We didn't thin it, just brushed it on. I will sand it again, just enough to make it dull so I ecan spray on a coat of white epoxy paint. This makes everything look tidy, protects the fiberglass from oil and other drips. It also makes it easy to spot leaks, not that you would ever get one from a Lycoming.