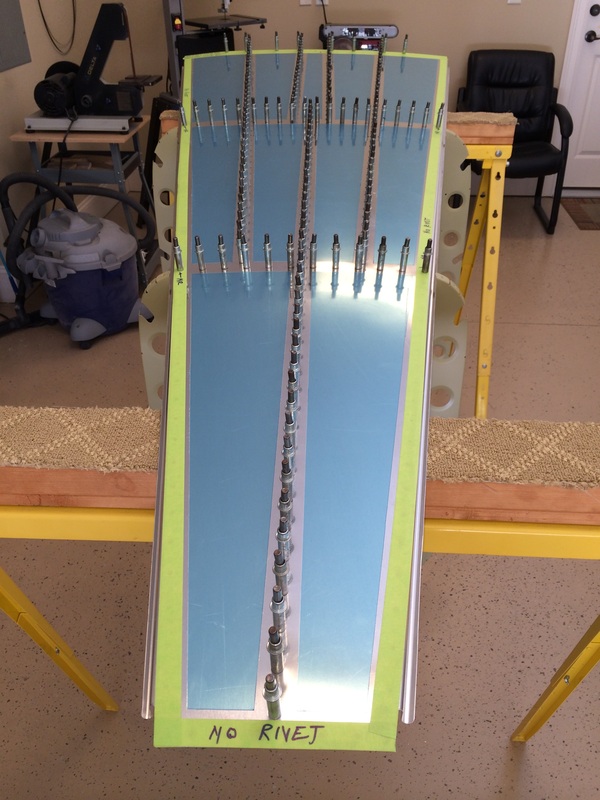

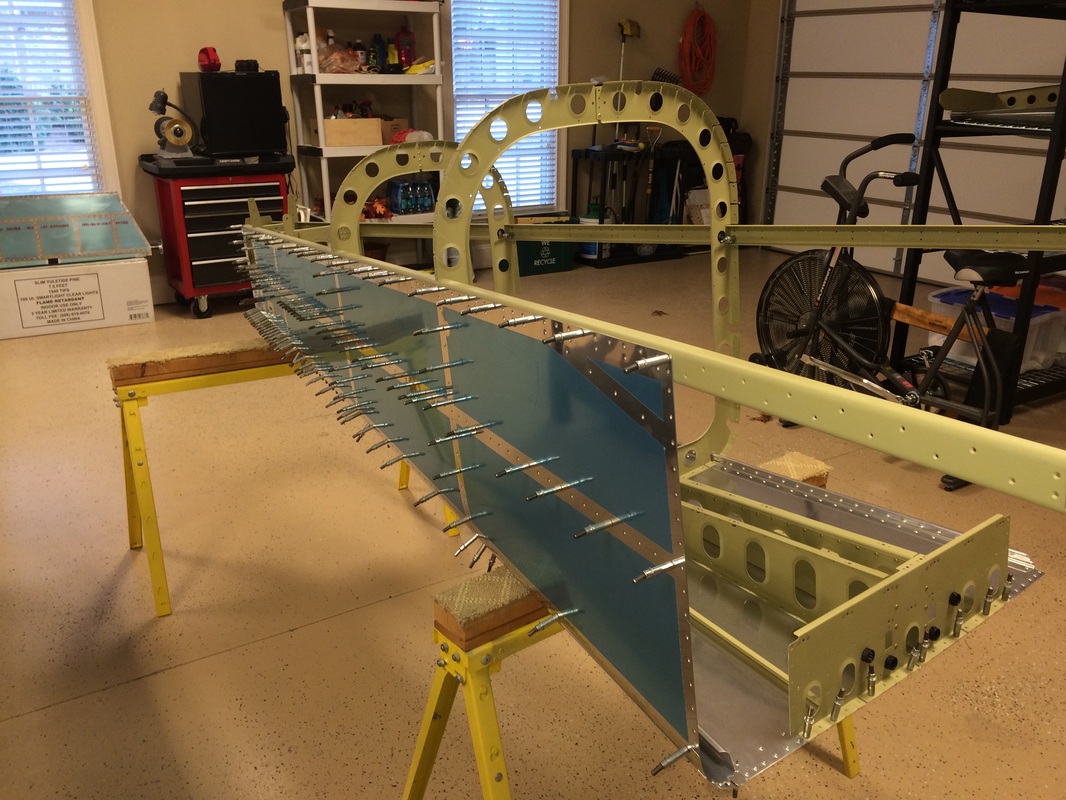

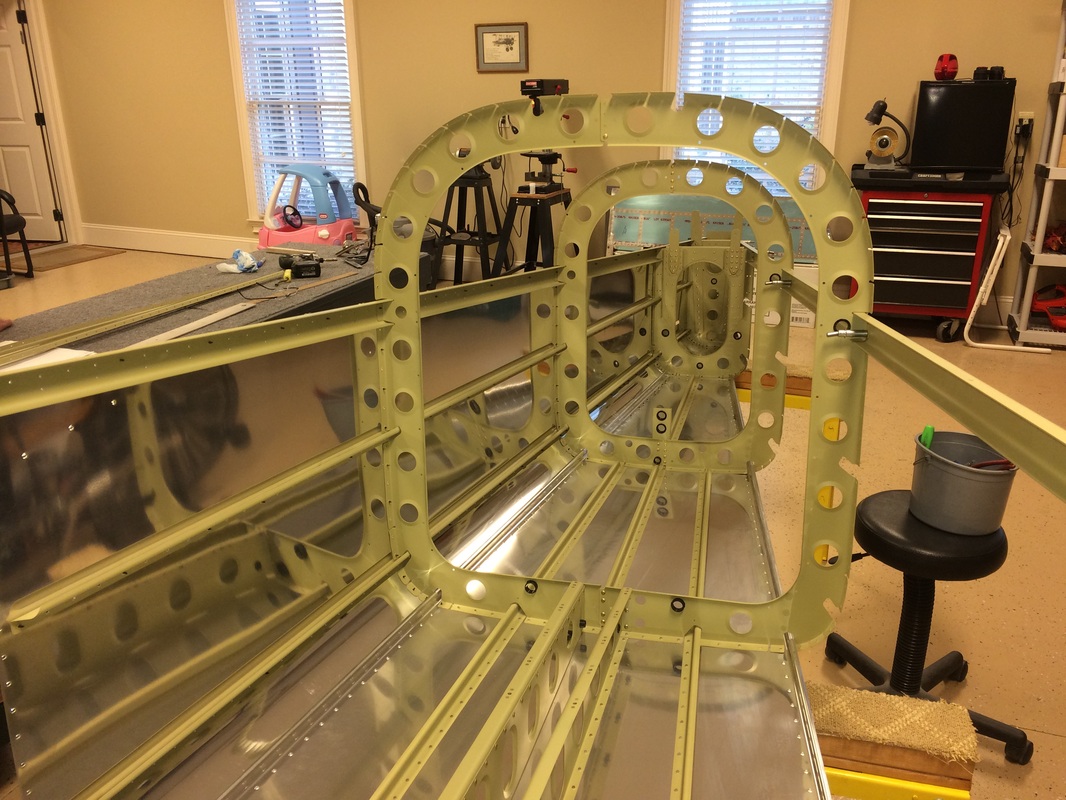

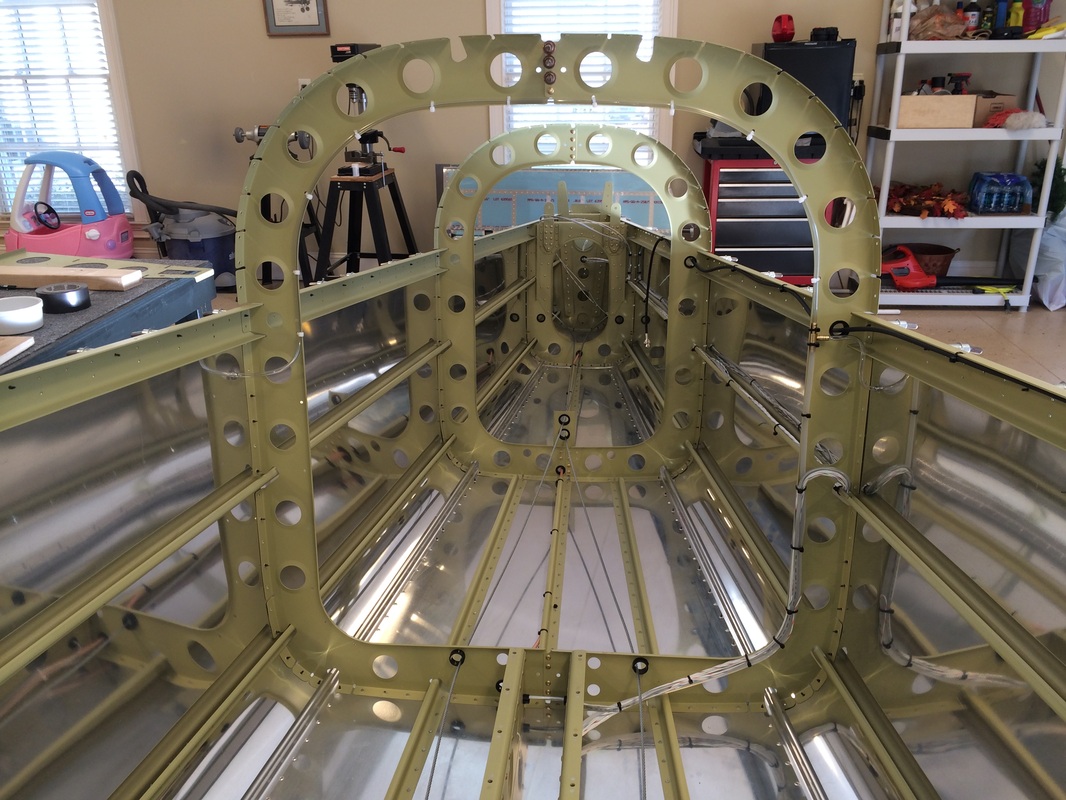

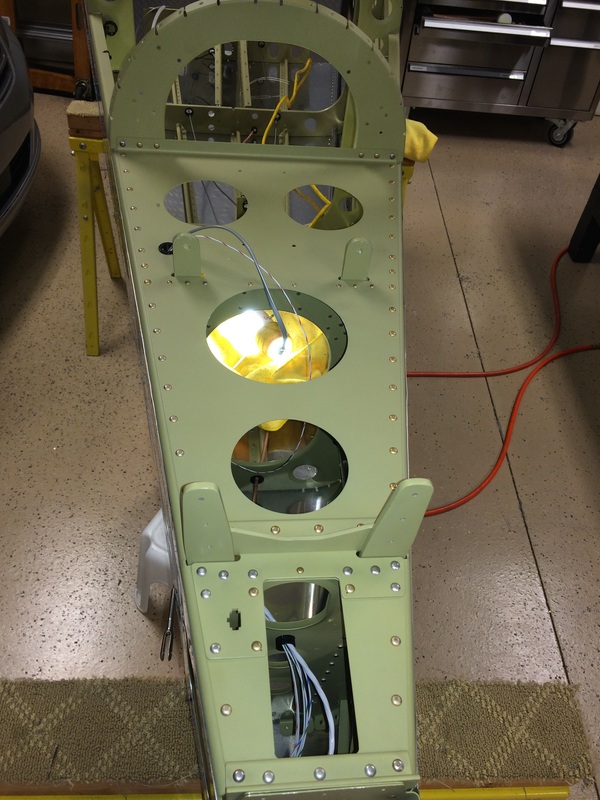

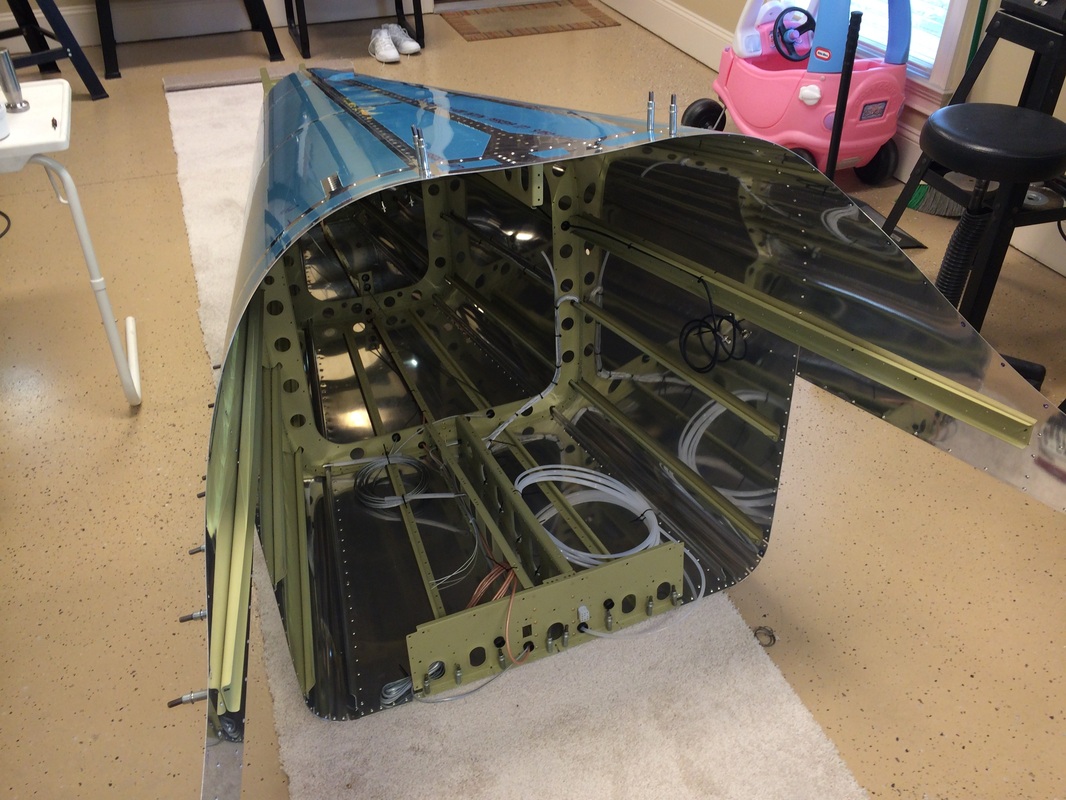

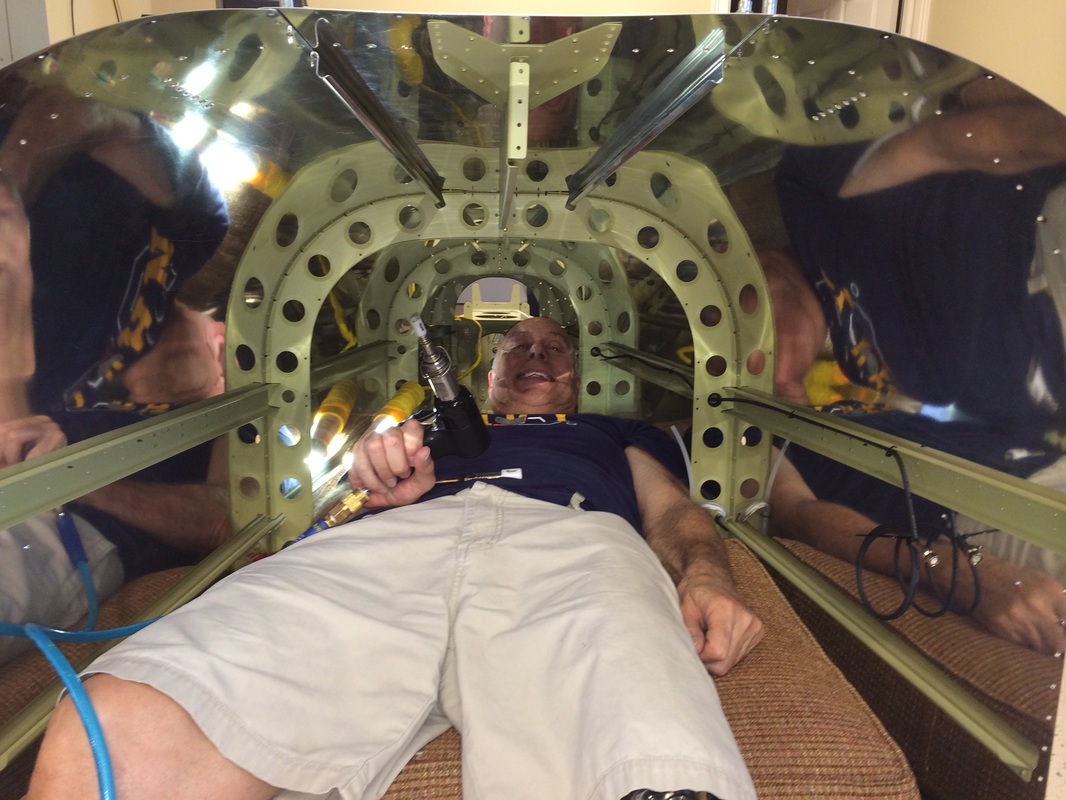

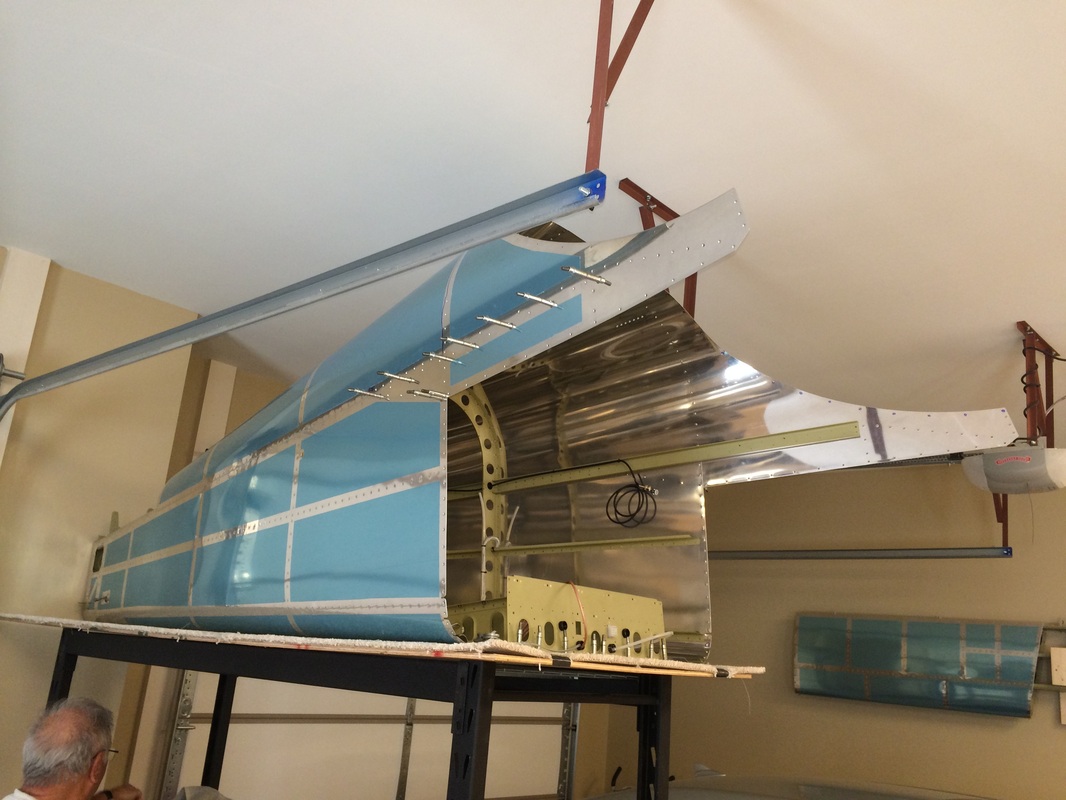

This section is the rear half of the fuselage. We are now at about 425 hours of build time and looks like we might have another 60-100 hours to go to finish this kit. The wings are on the way, so we are pushing to finish this kit by February 28, 2014. News flash, we have been putting in 36 hours a week combined and are now at 600 hours and still have more to go on the tail. If we finish in March, the kit will have taken 4 calendar months and most likely 680 hours.

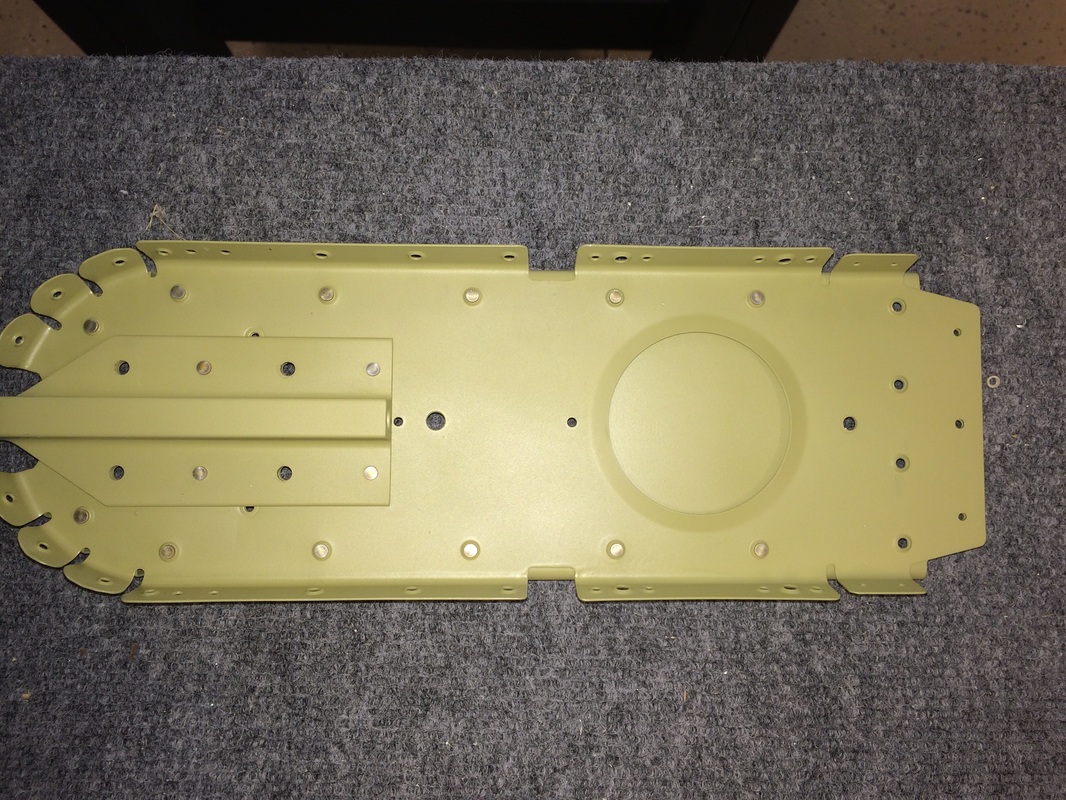

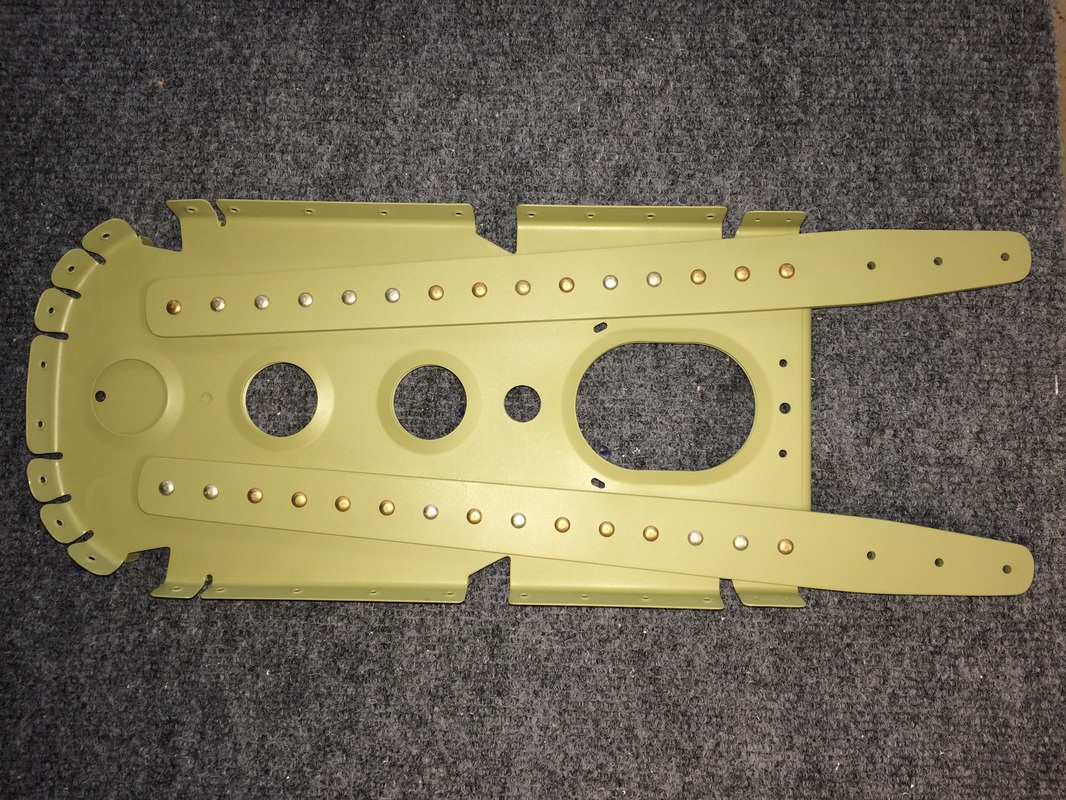

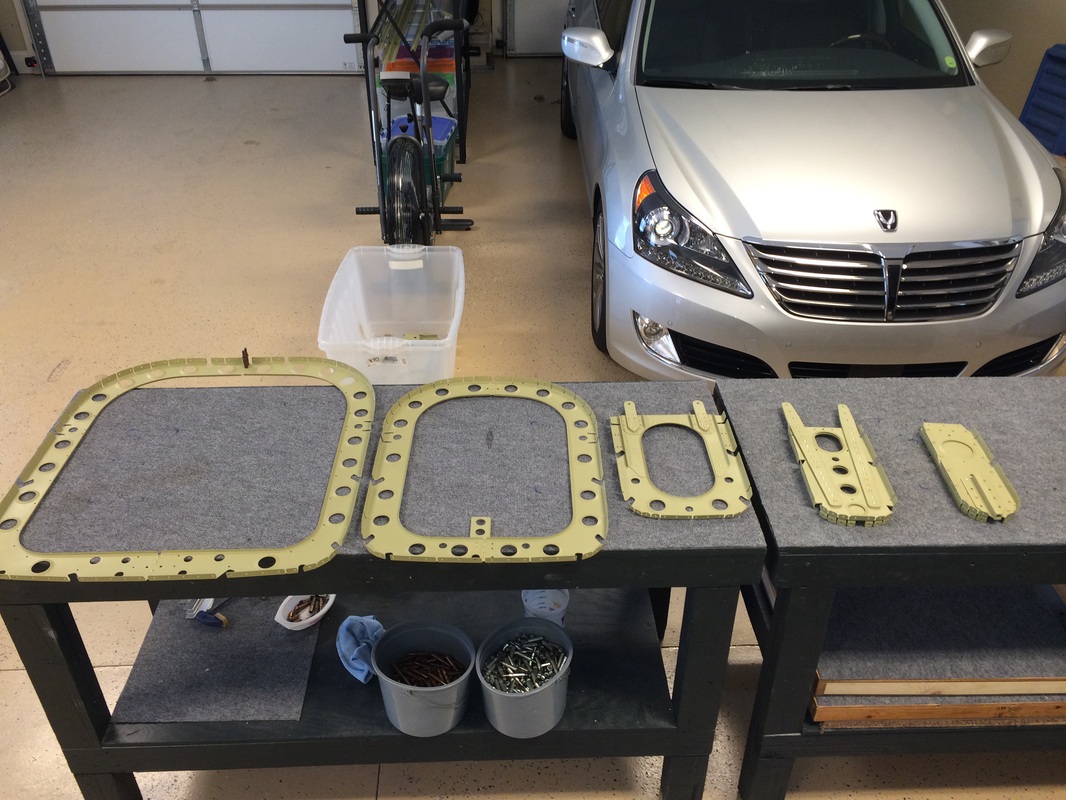

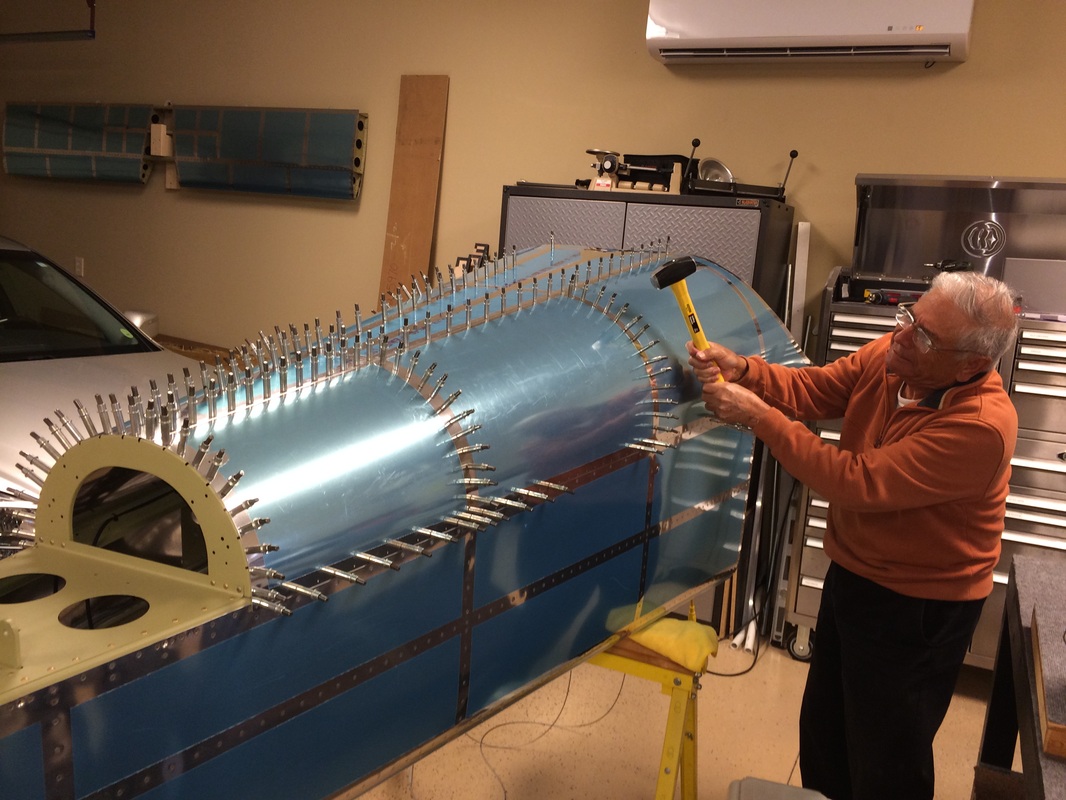

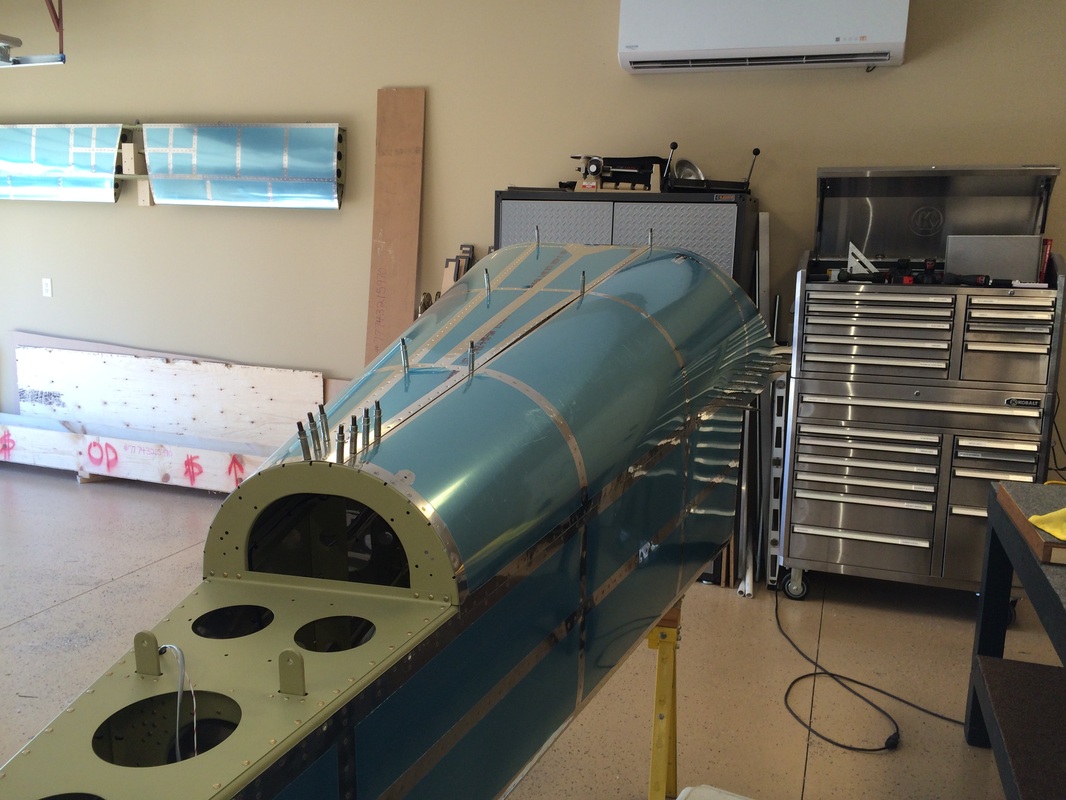

Rafael went to Florida to play golf for a week and Robin was kind enough to fill in and help me with the priming. We use the out door method, sounds crude, but works great. Robin runs and gets me apart, I spray half and he hangs it up to dry and gets me another one. After 20 minutes the parts and dry and we paint the other half. This way I can hold and turn the part to get good coverage with little fuss and never touch wet paint. I use a good spay respirator and by spraying outdoors with a little breeze the overspray drys quickly and immediately dissipates.

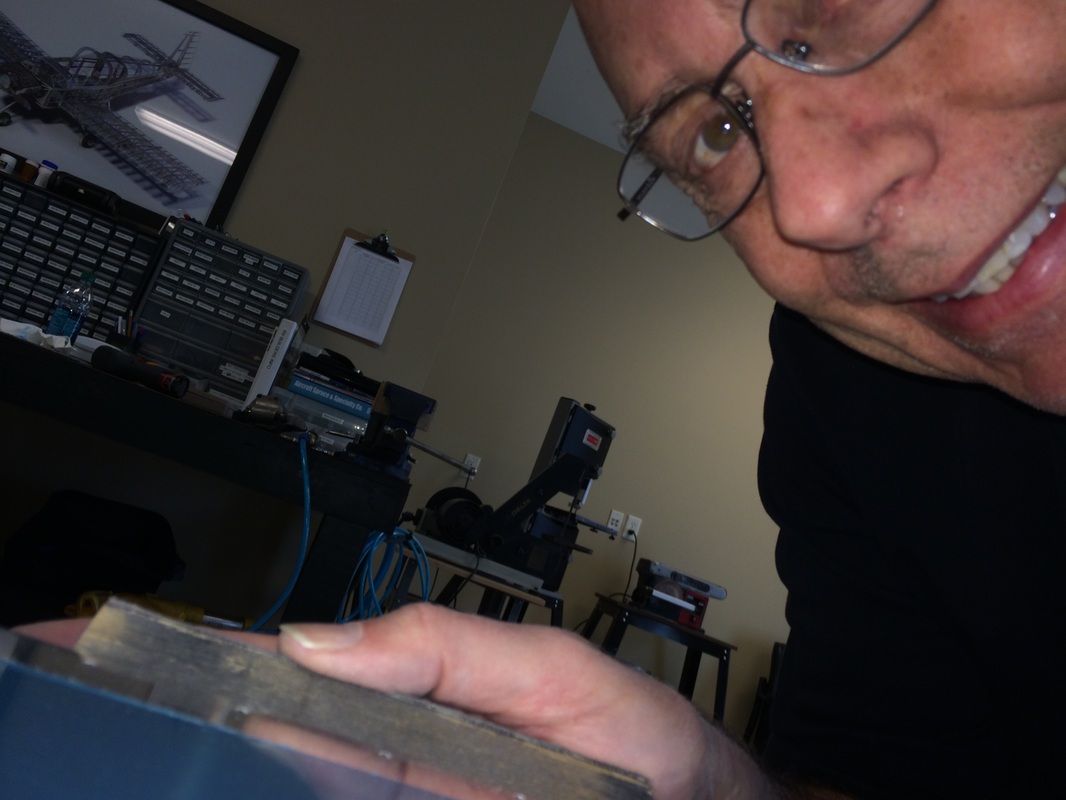

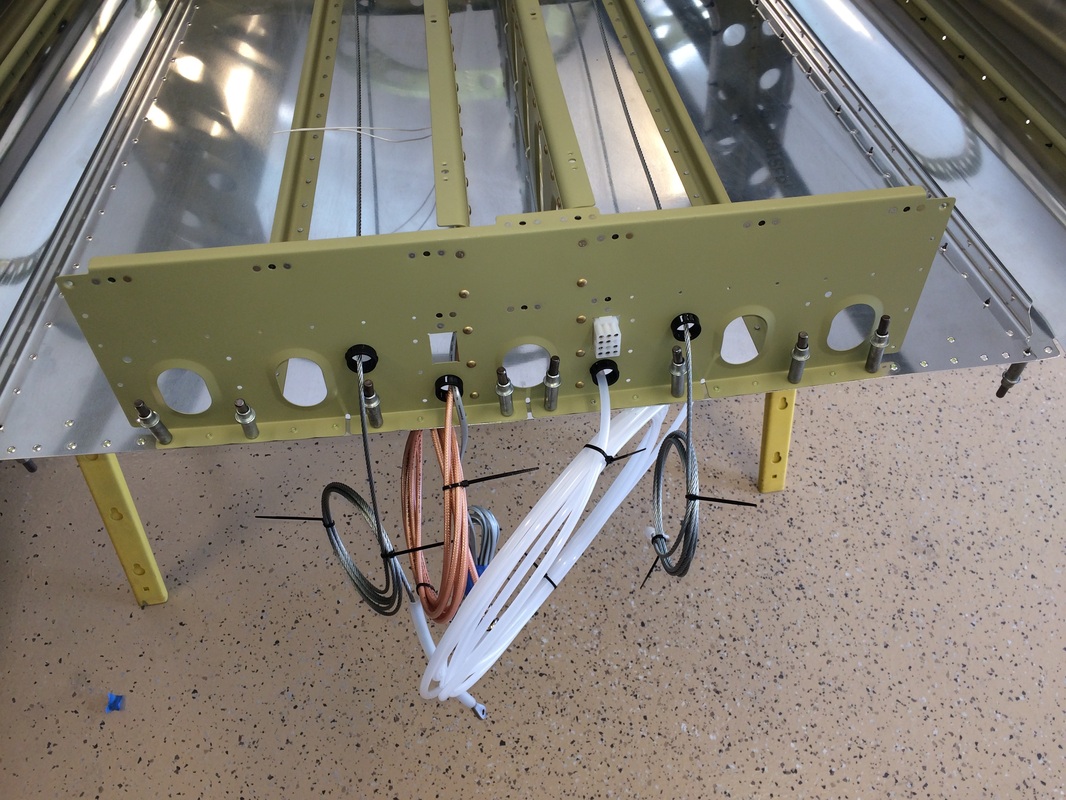

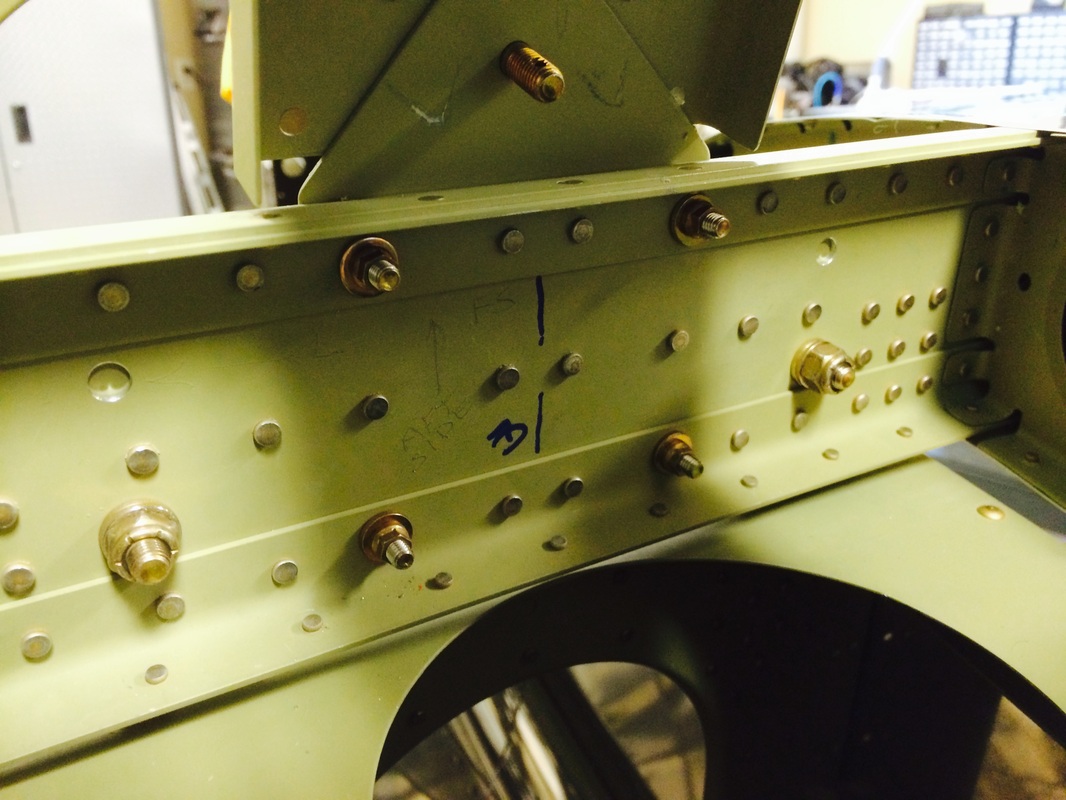

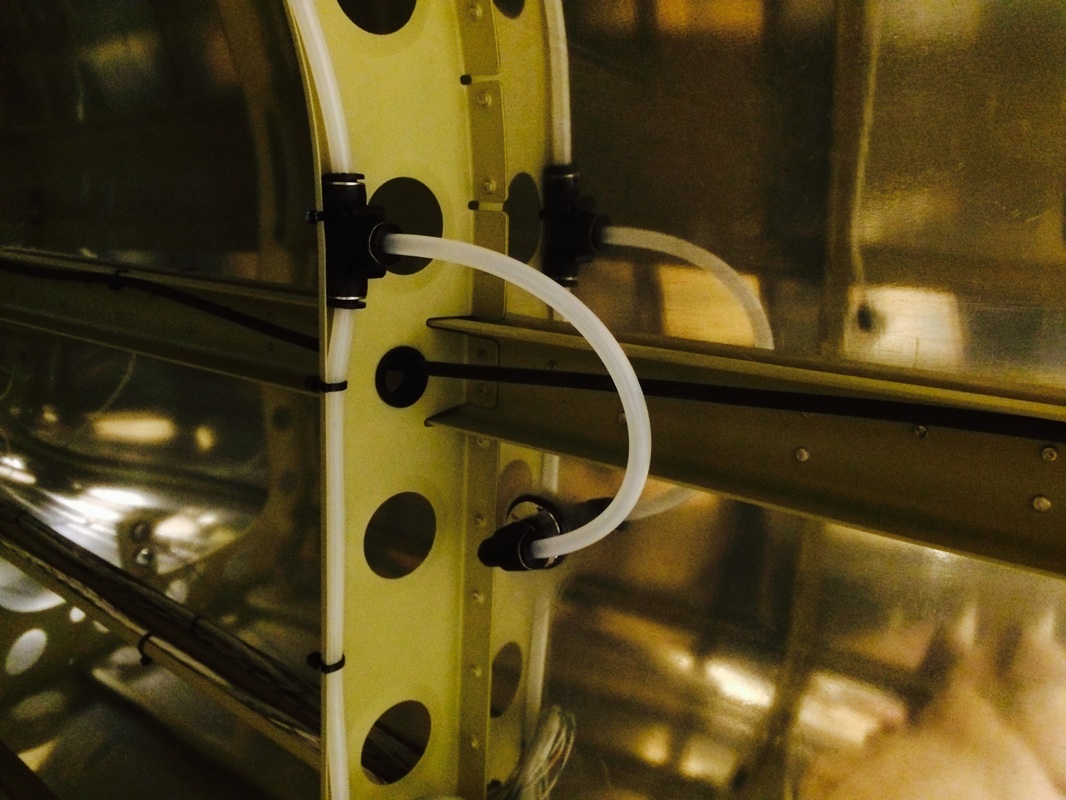

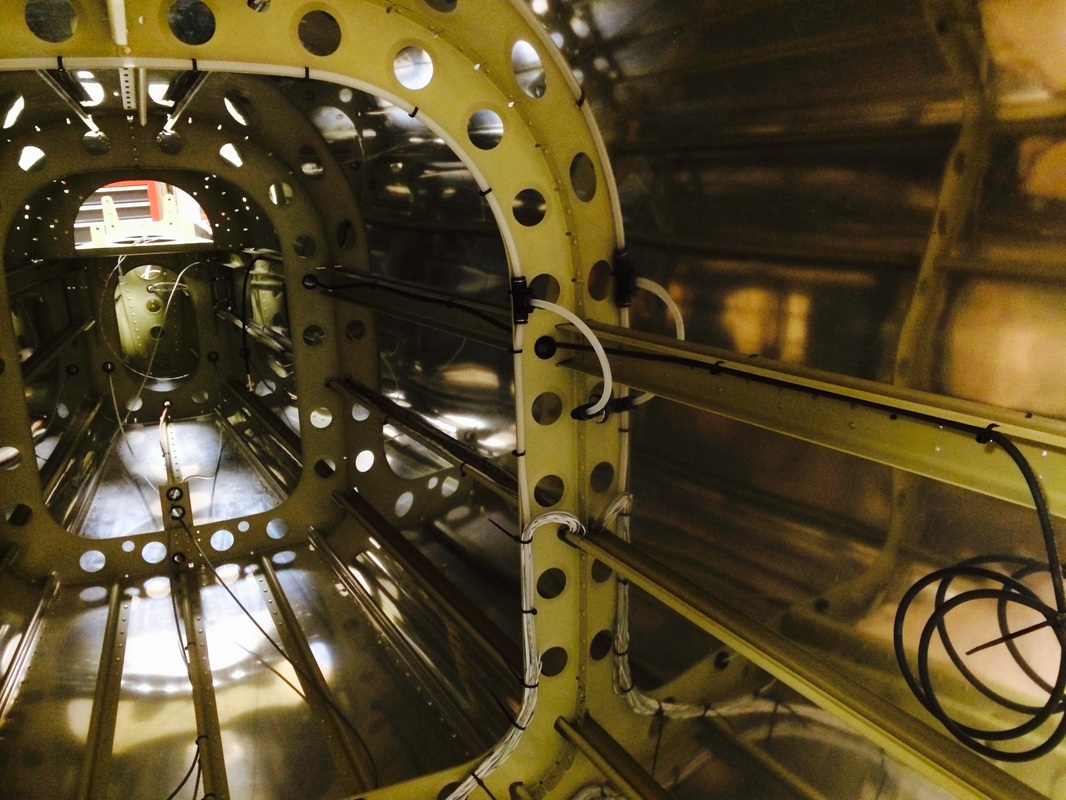

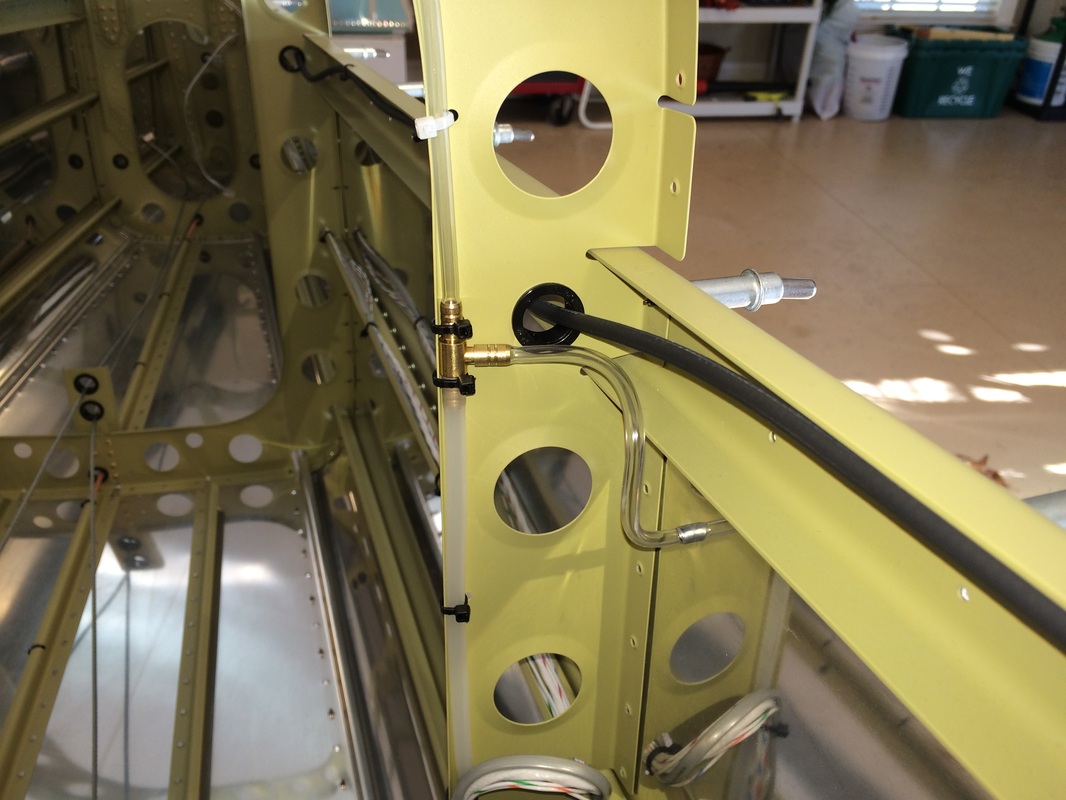

We change out the "T" fitting after breaking the plastic one. This brass unit seemed a little more professional but I still am not enamored with the "pop" rivet static inlets for IFR work, I think we are going to spend the $35 and buy the Cleveland Tool static air kit and get rid of the aquarium tubing and pop rivets. I'm not saying they are bad, but I think the Cleveland system is better and the push and lock fittings have not failed me in the RV 7. I like the positive lock on fittings and standard pitot tubing. It's just personal and Rafael is good with the change so I order the kit today.

Note: We removed Vans static pop rivet system and installed the Cleveland Tool kit. It is show further down on this page.

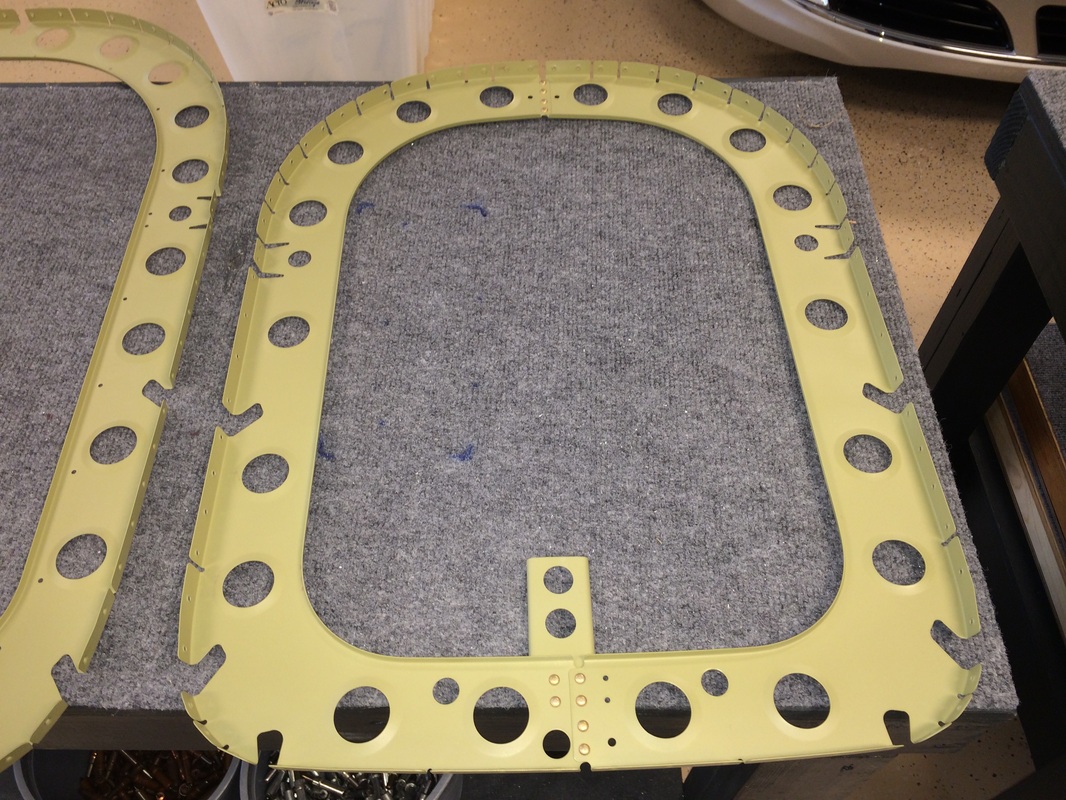

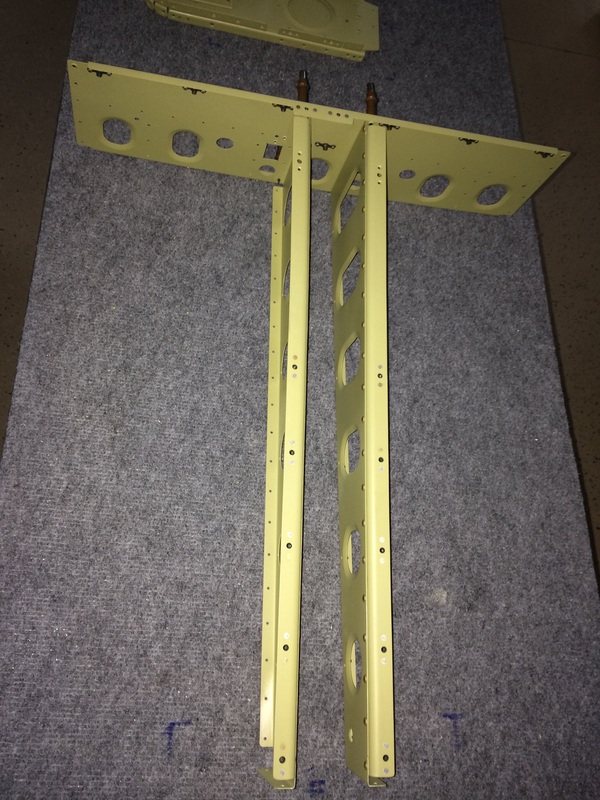

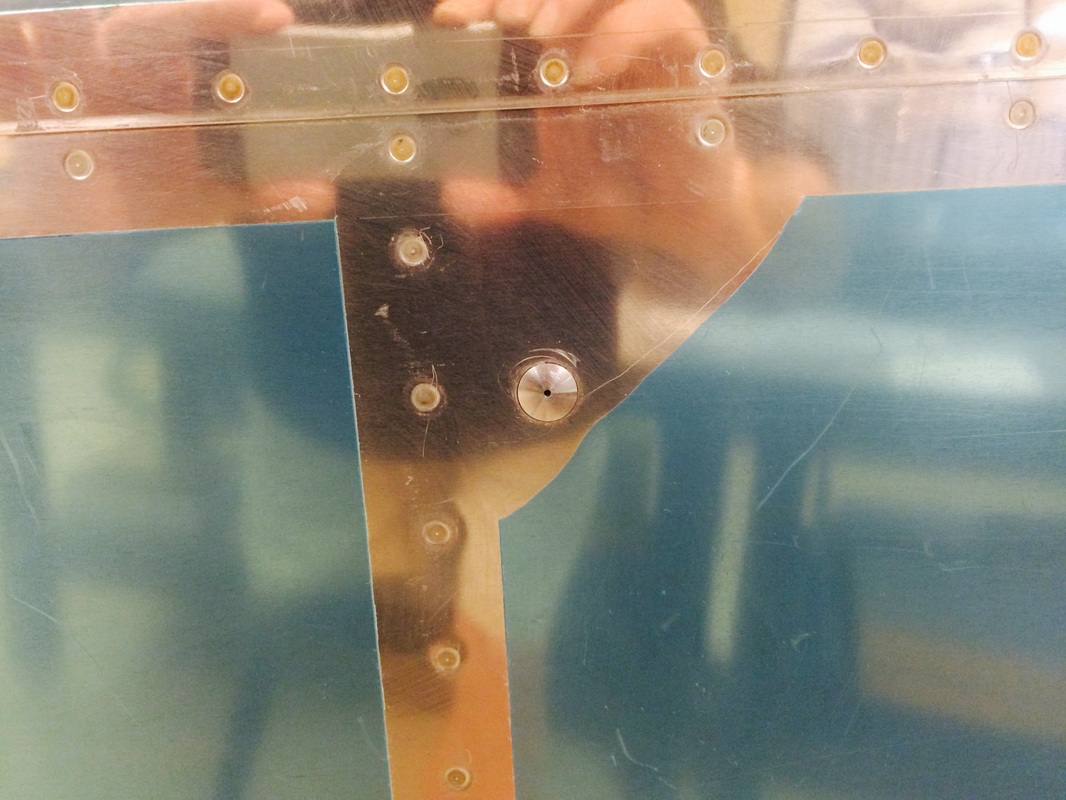

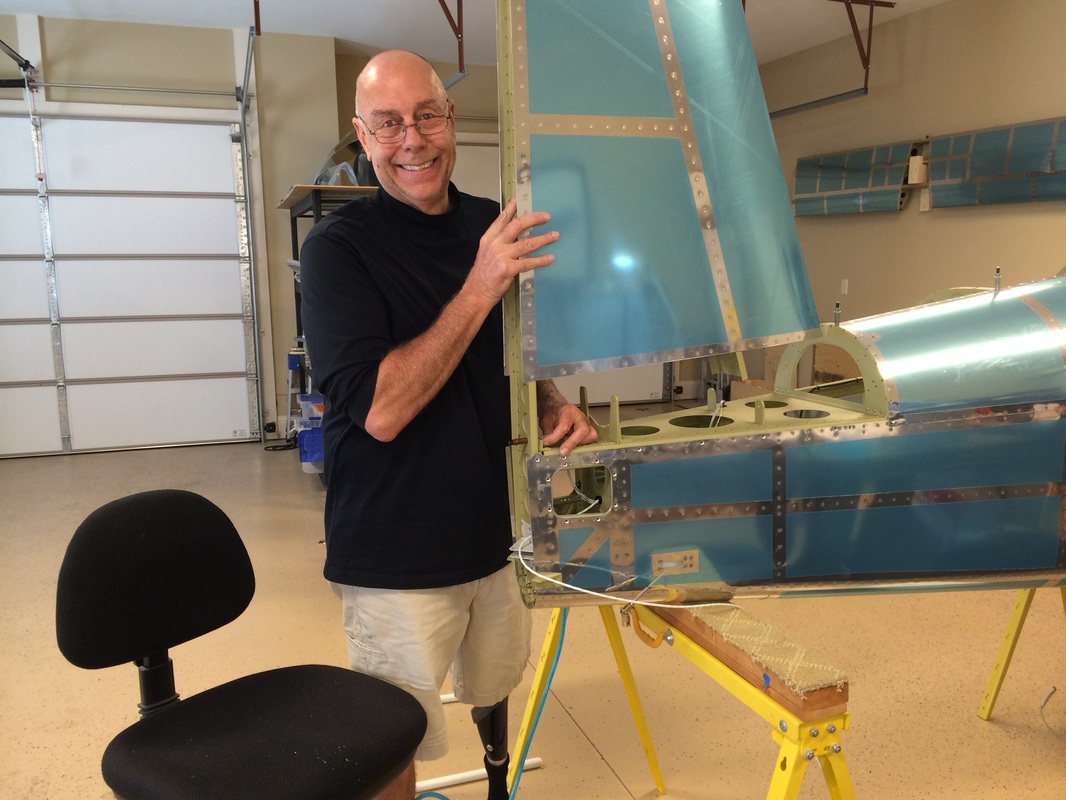

Fitting the vertical stabilizer to the rear most frame and final drilling. It fit well except for interference from the 2 plate nuts that hold the stabilizer fairing in place. We made a few modifications and changed the plate nut to a K1000 vs K1100 and managed to keep the flat head by countersinking the skin and flange. We will also need to shorten the # 6 screws to 3/8"