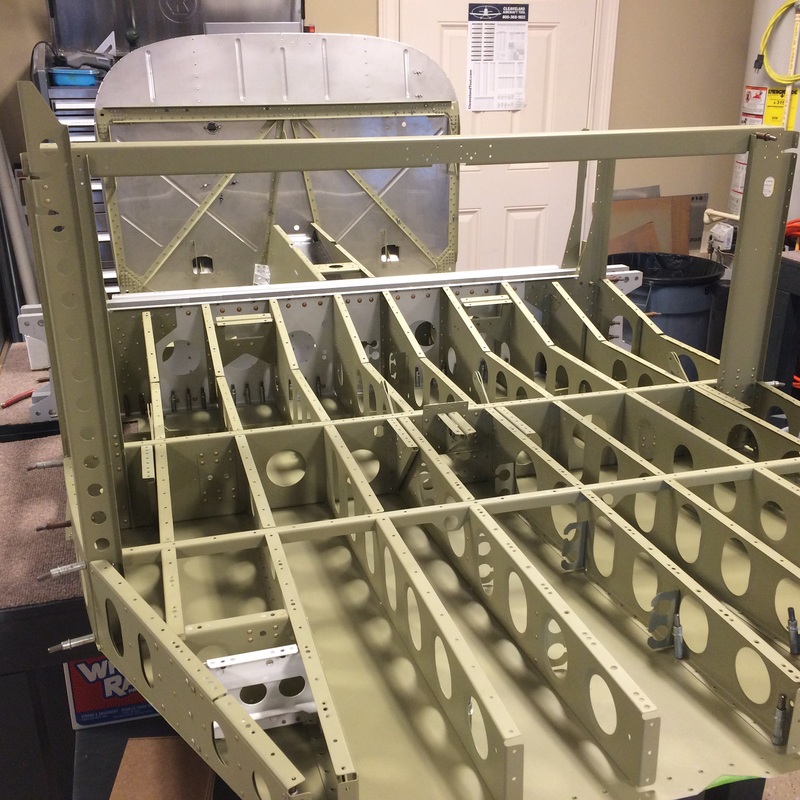

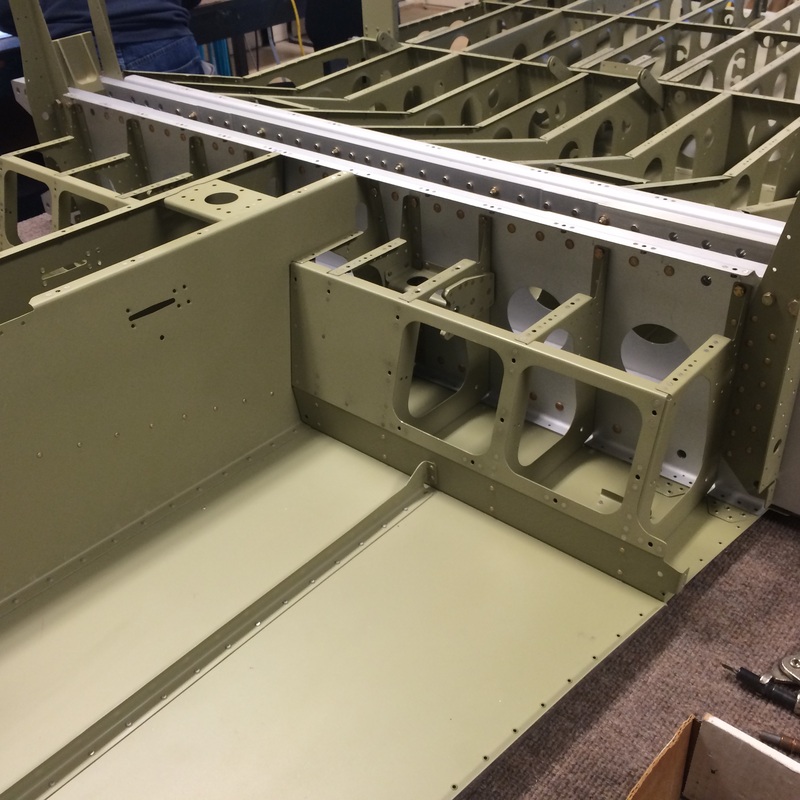

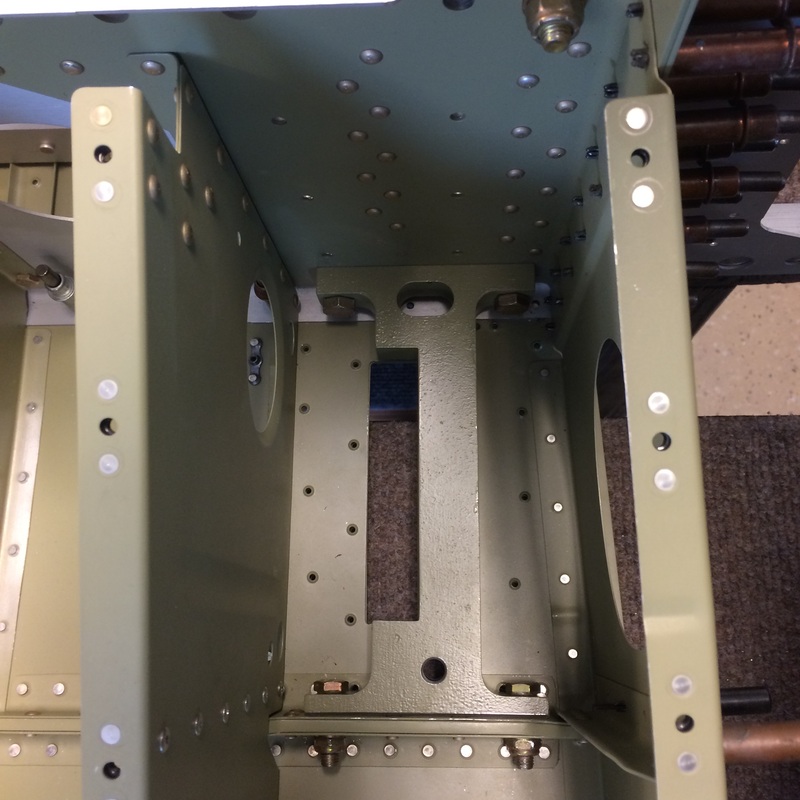

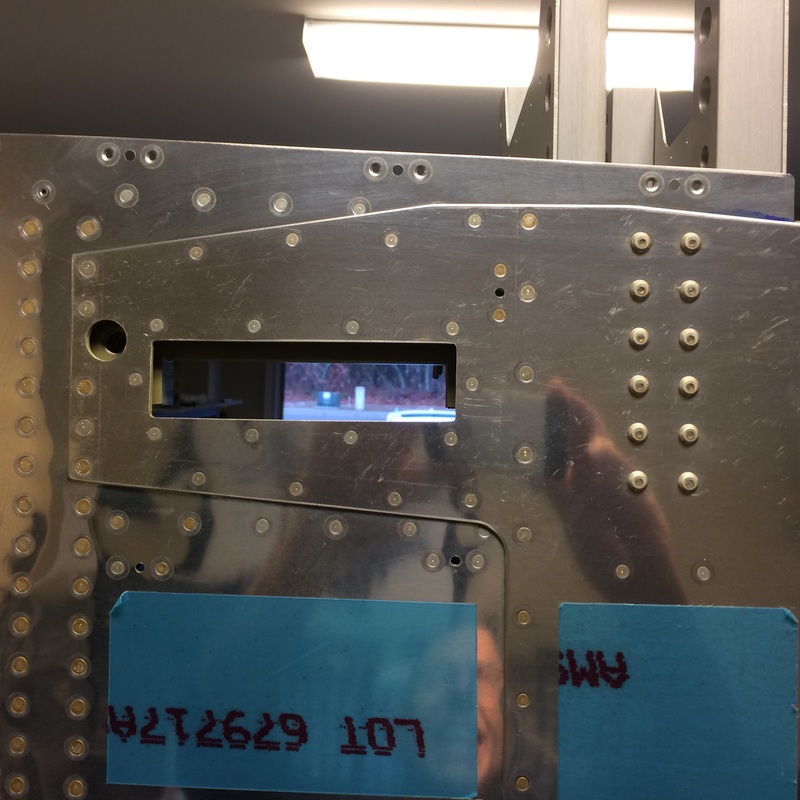

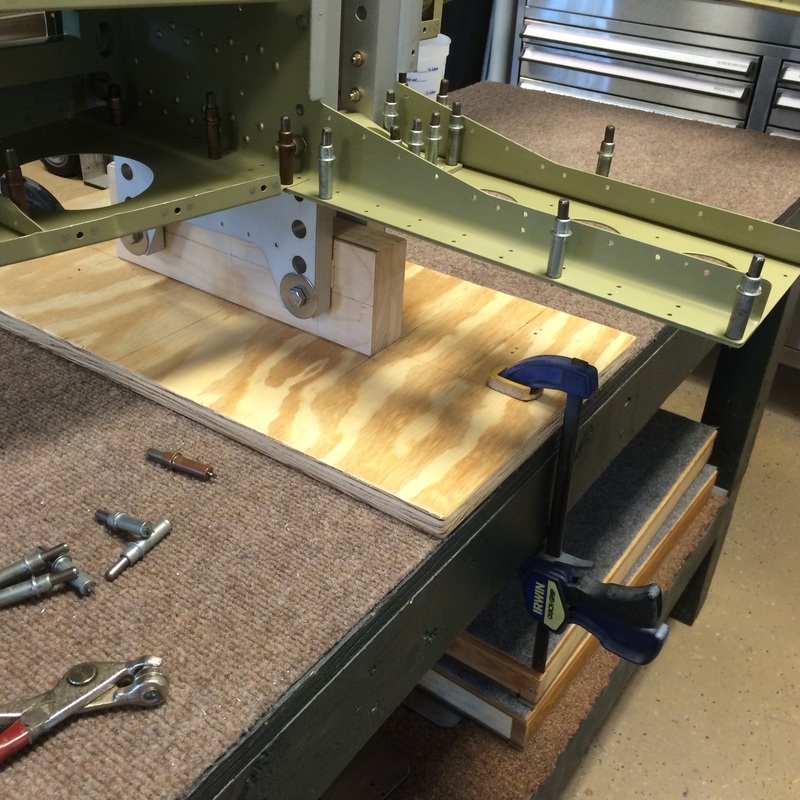

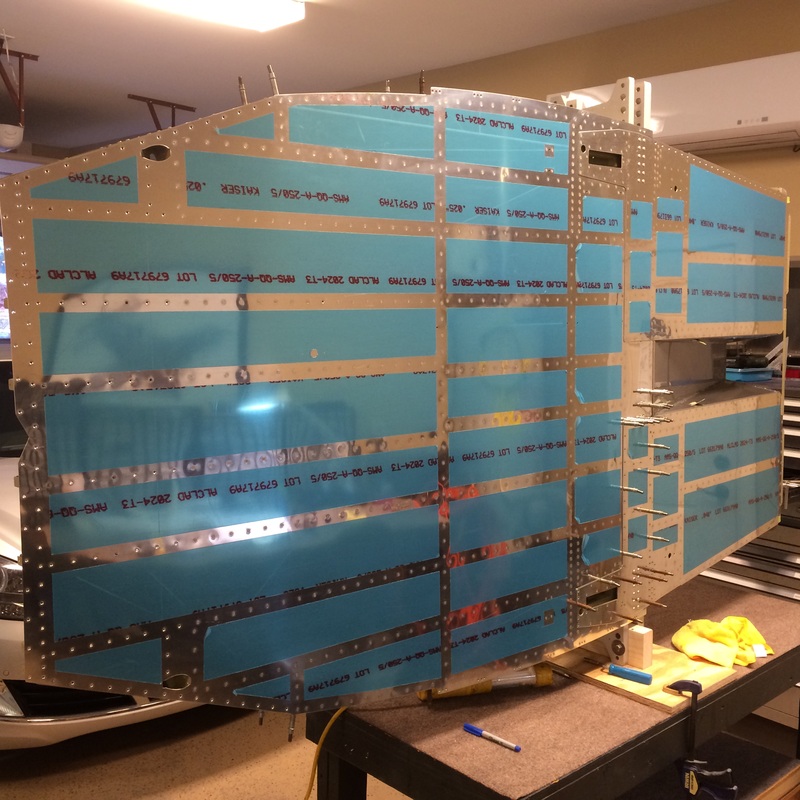

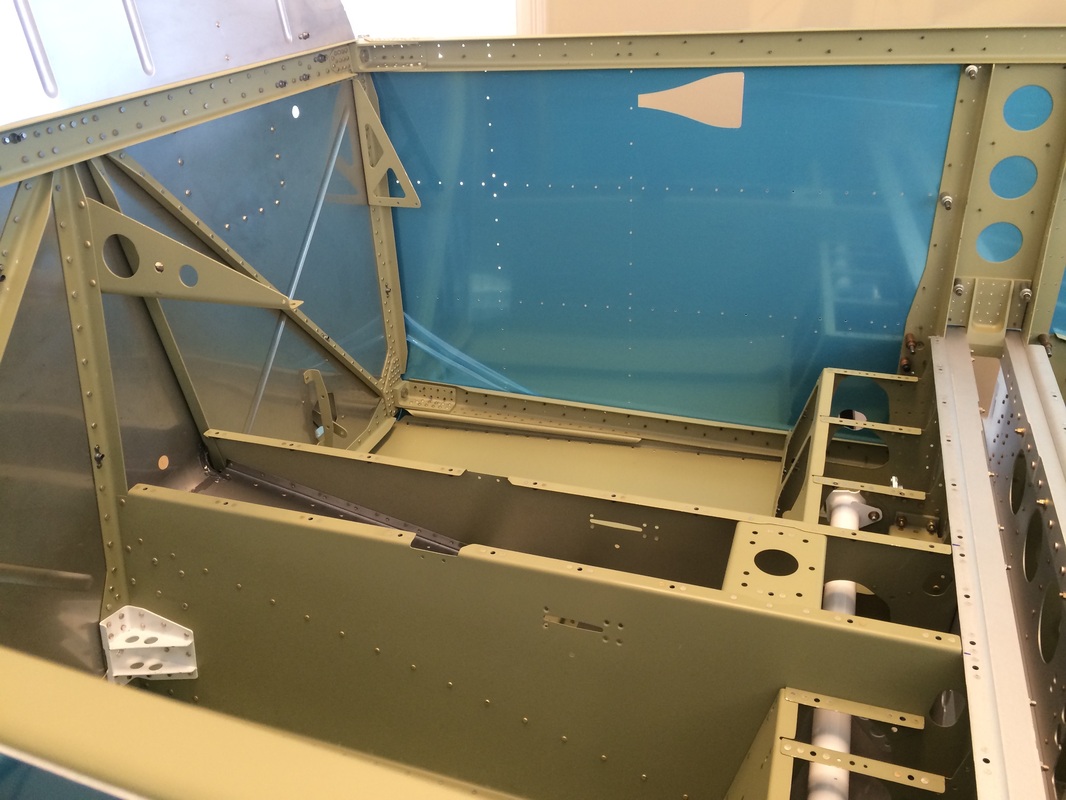

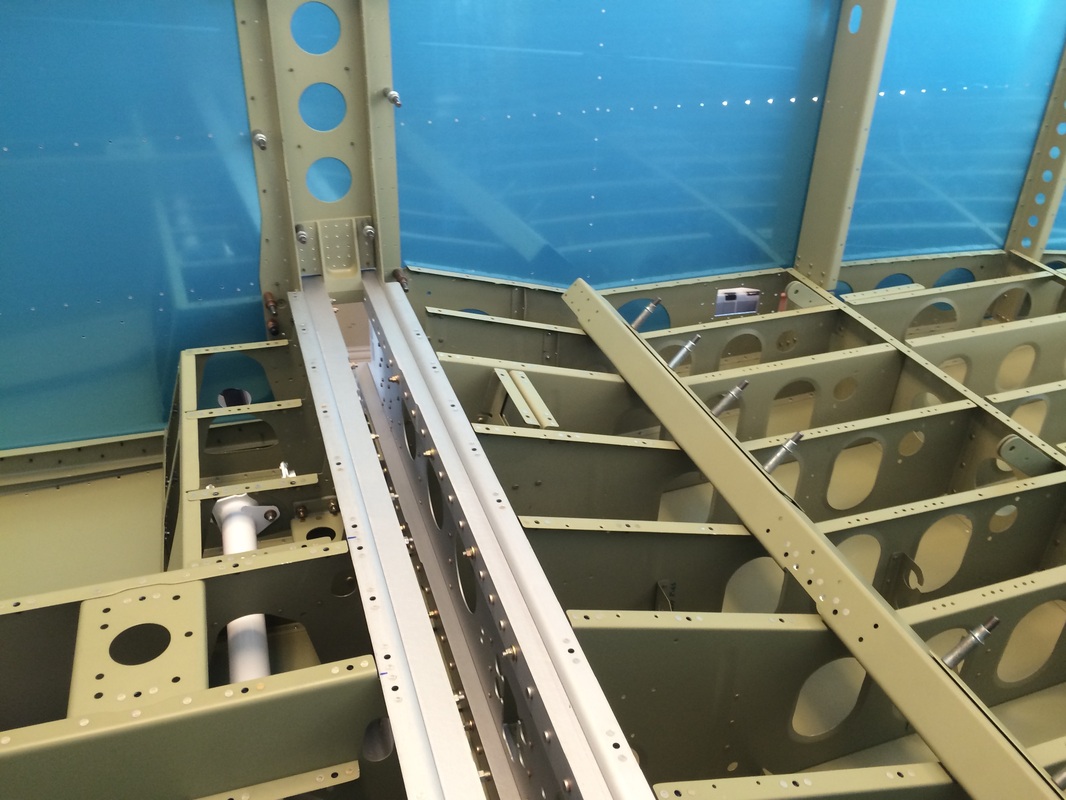

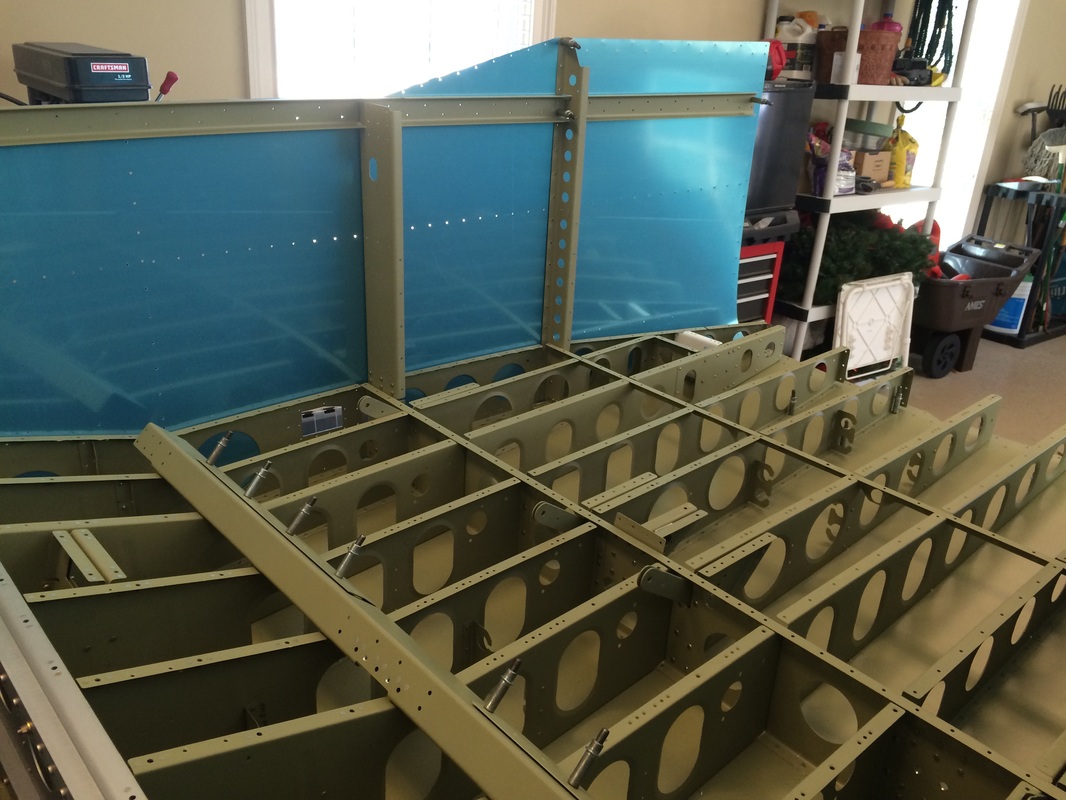

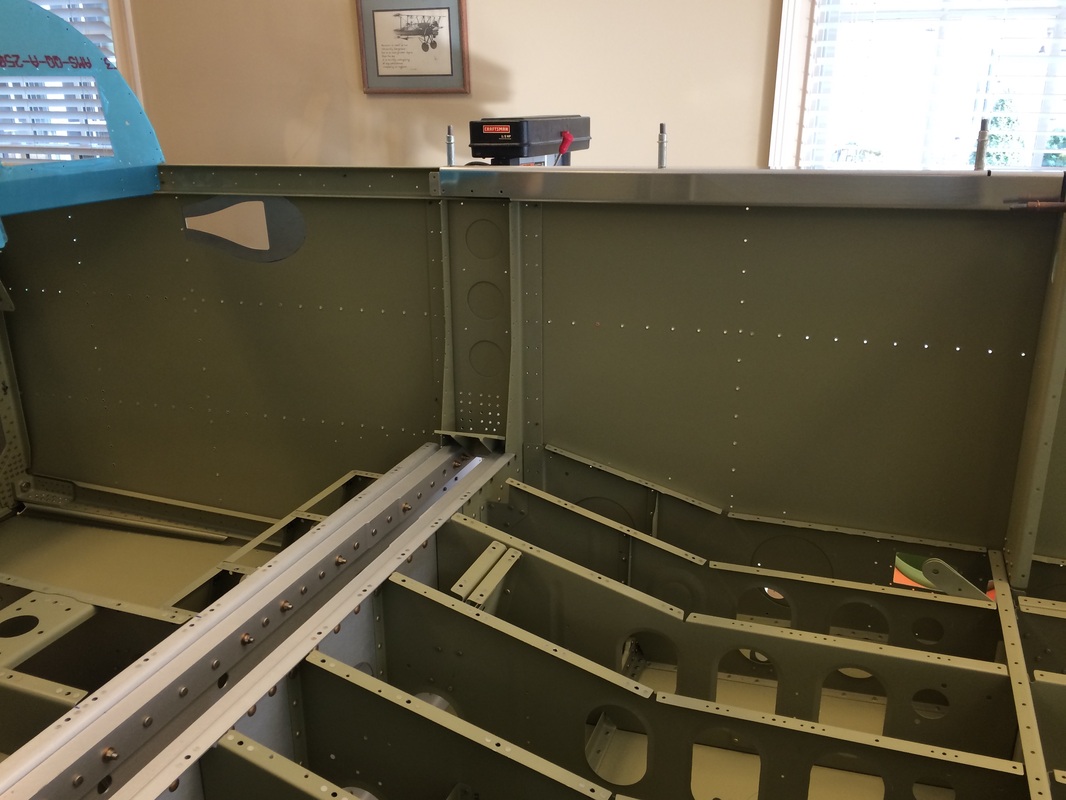

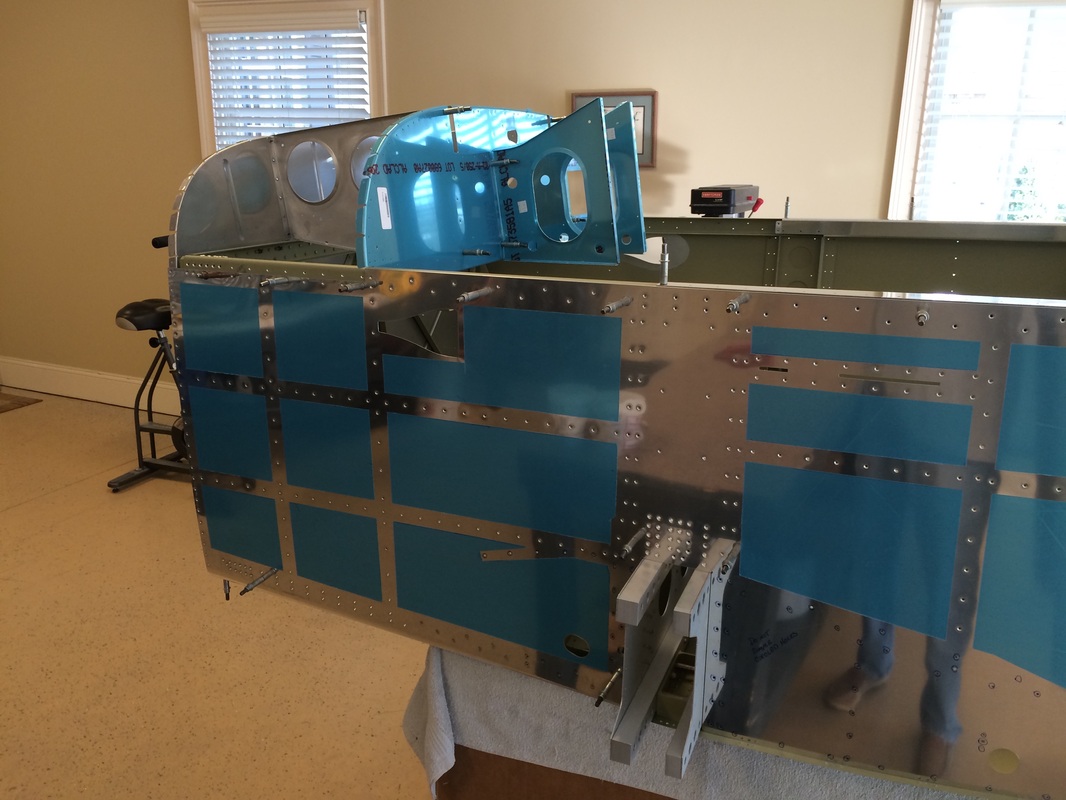

Forward Mid Fuselage Side Structure - Section 29

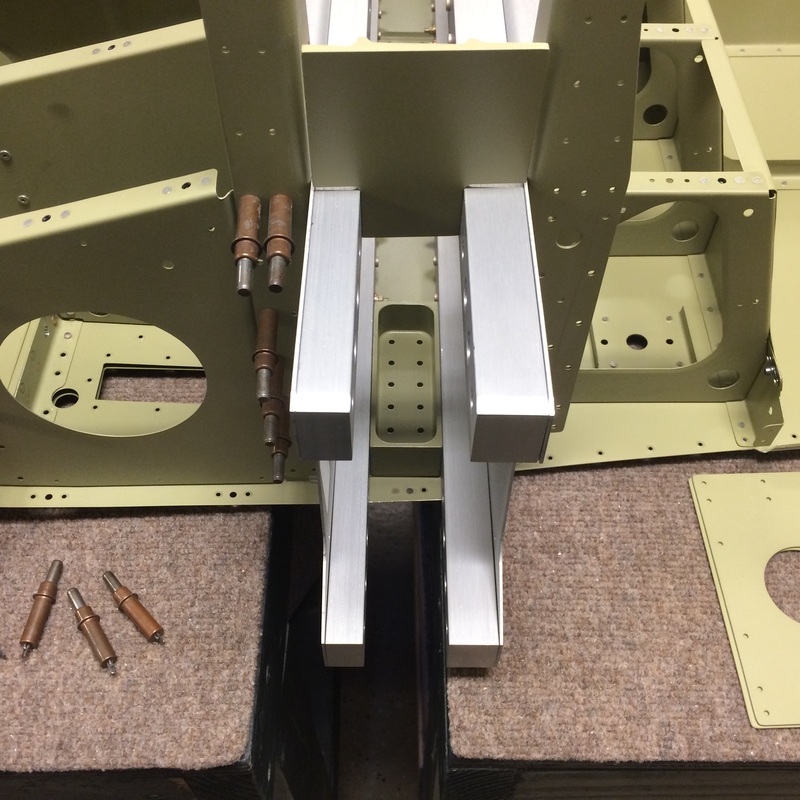

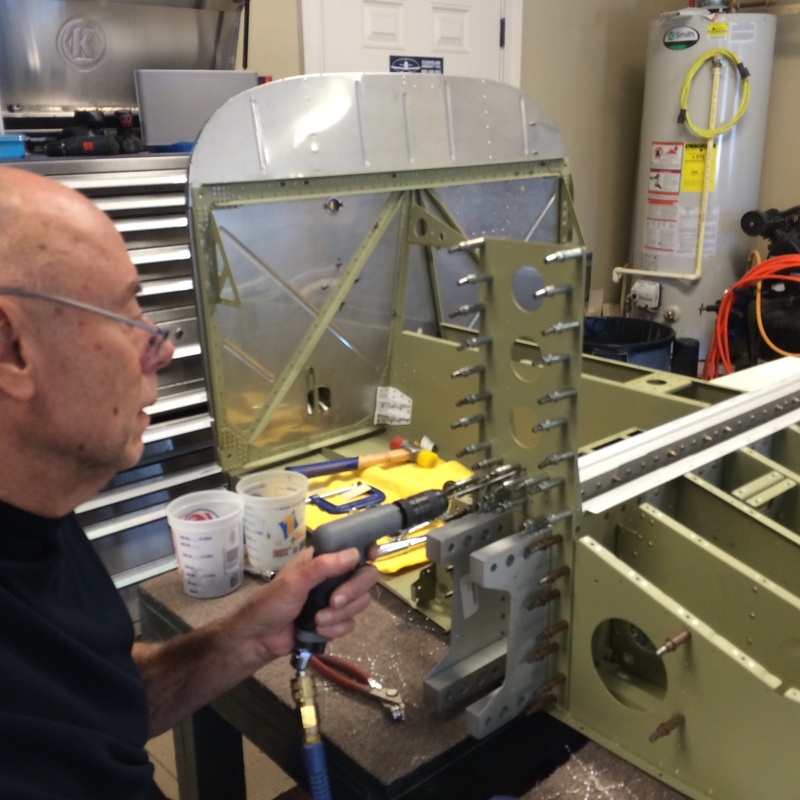

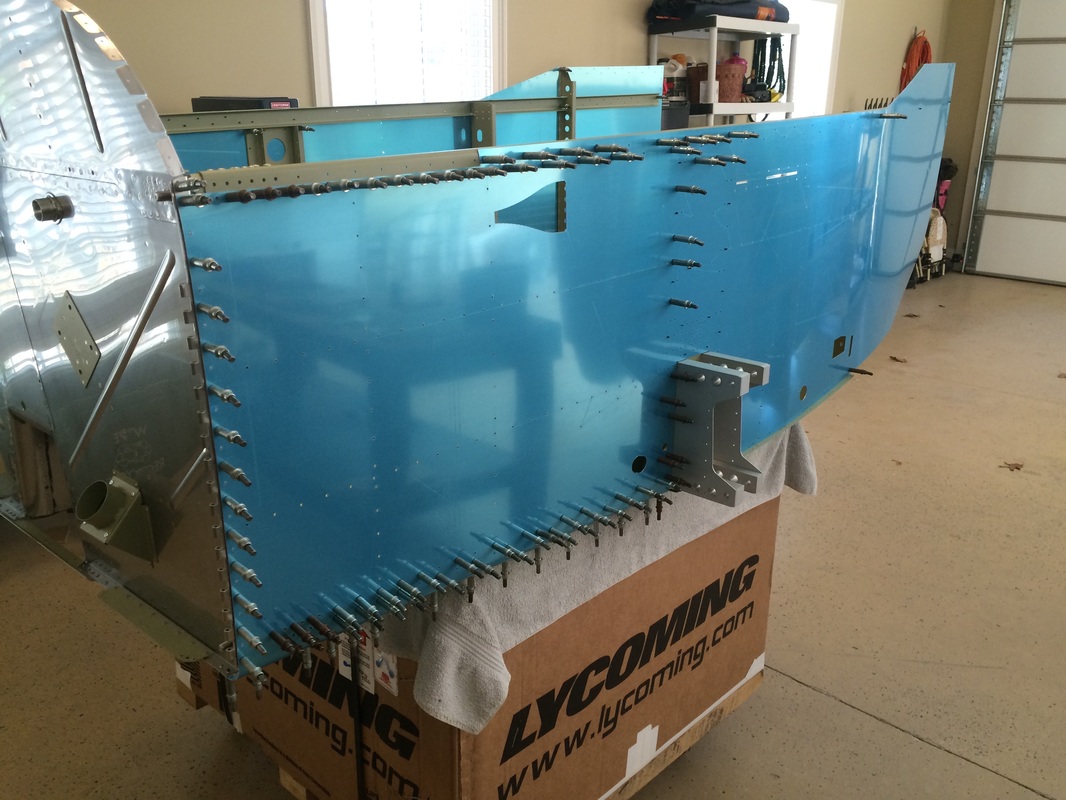

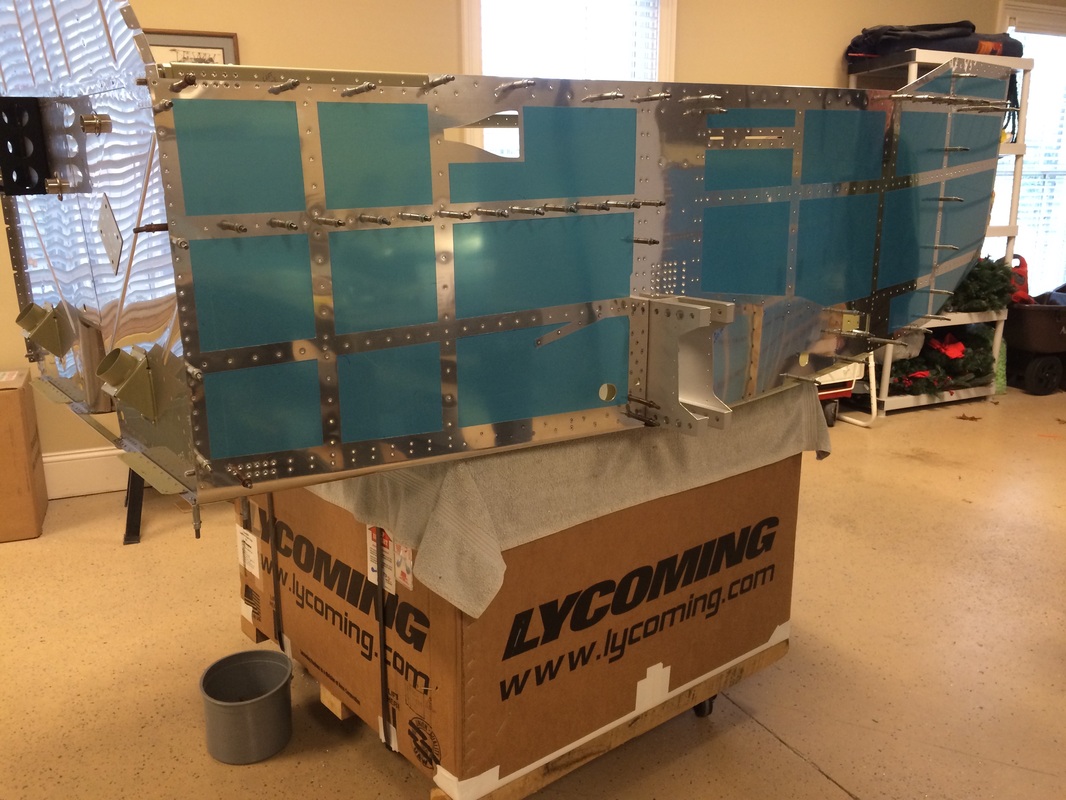

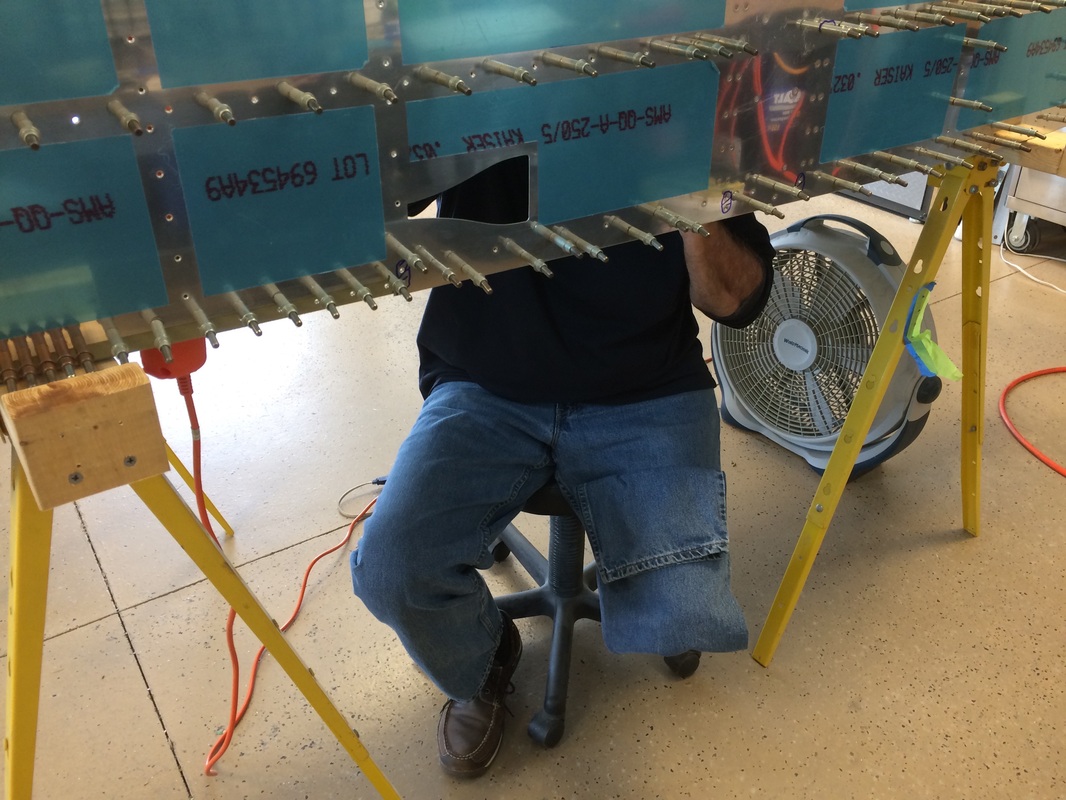

Trimming and installing the hinges for the cowl was more difficult then I though they needed to be. I did get some movement of the shim during the process on the first hinge and change the process from the plans slightly for the second one. I started with the hole shown in the plans and used side clamps every 3" or so to keep the hinge shim line in place and located behind the skin hole. This worked well.