Wing Assembly - Section 14

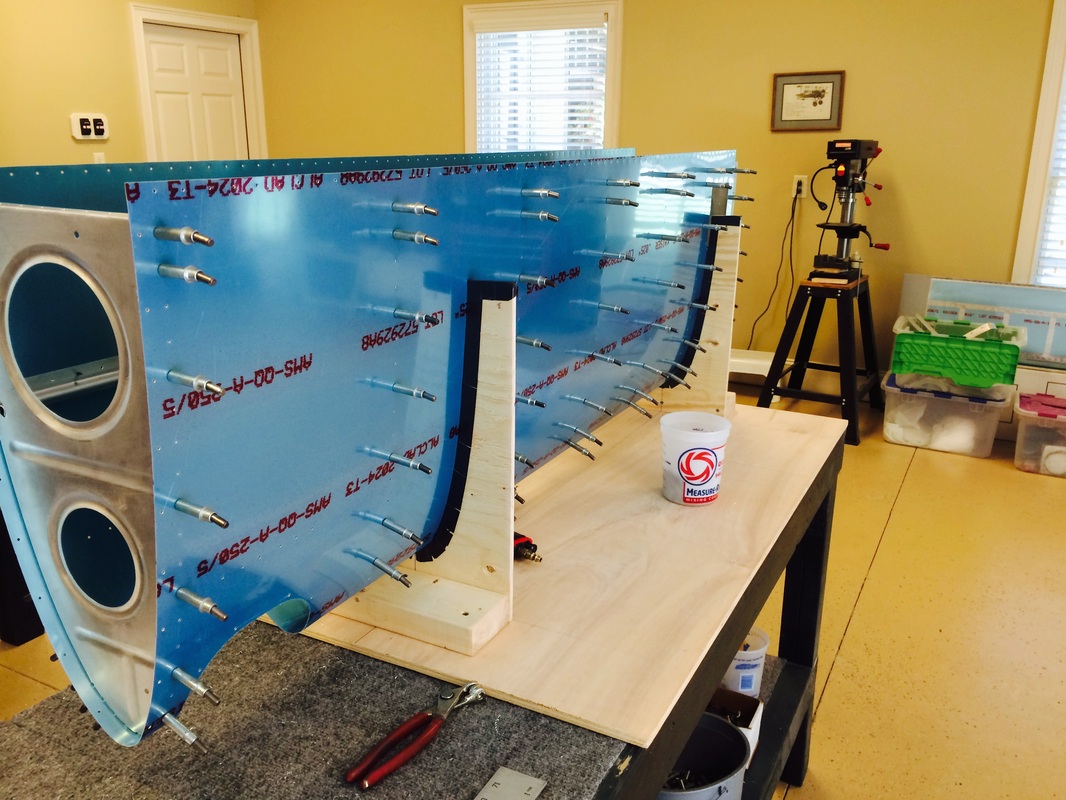

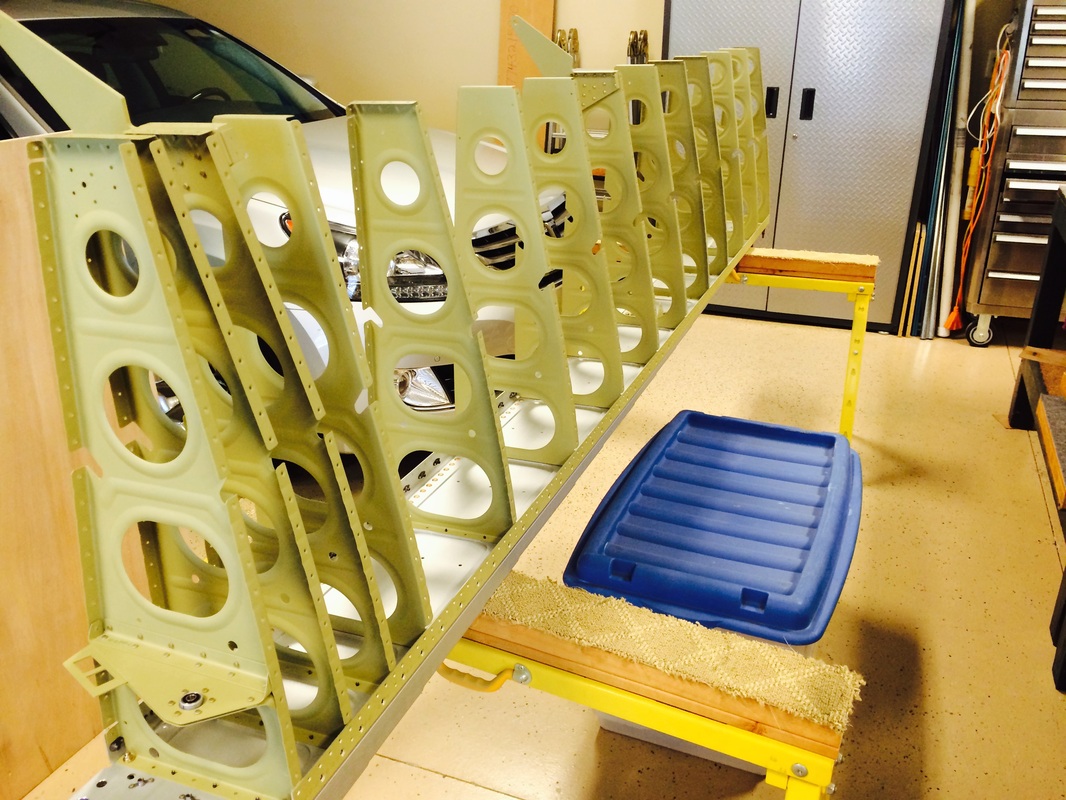

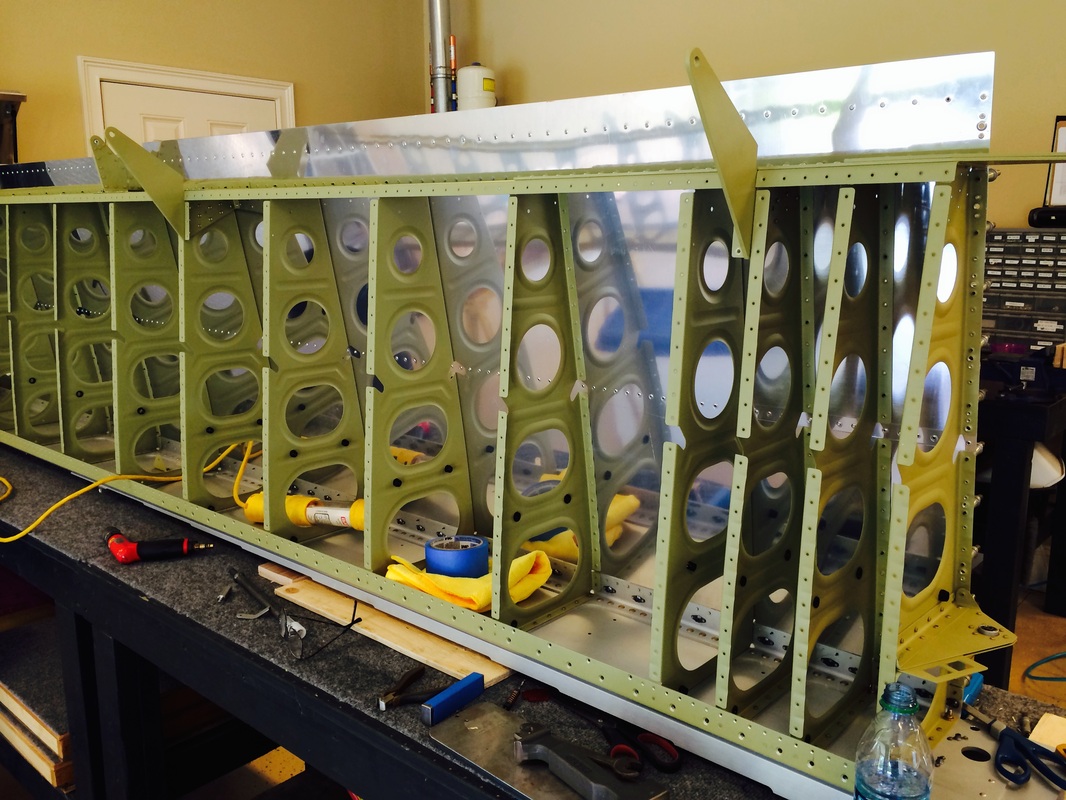

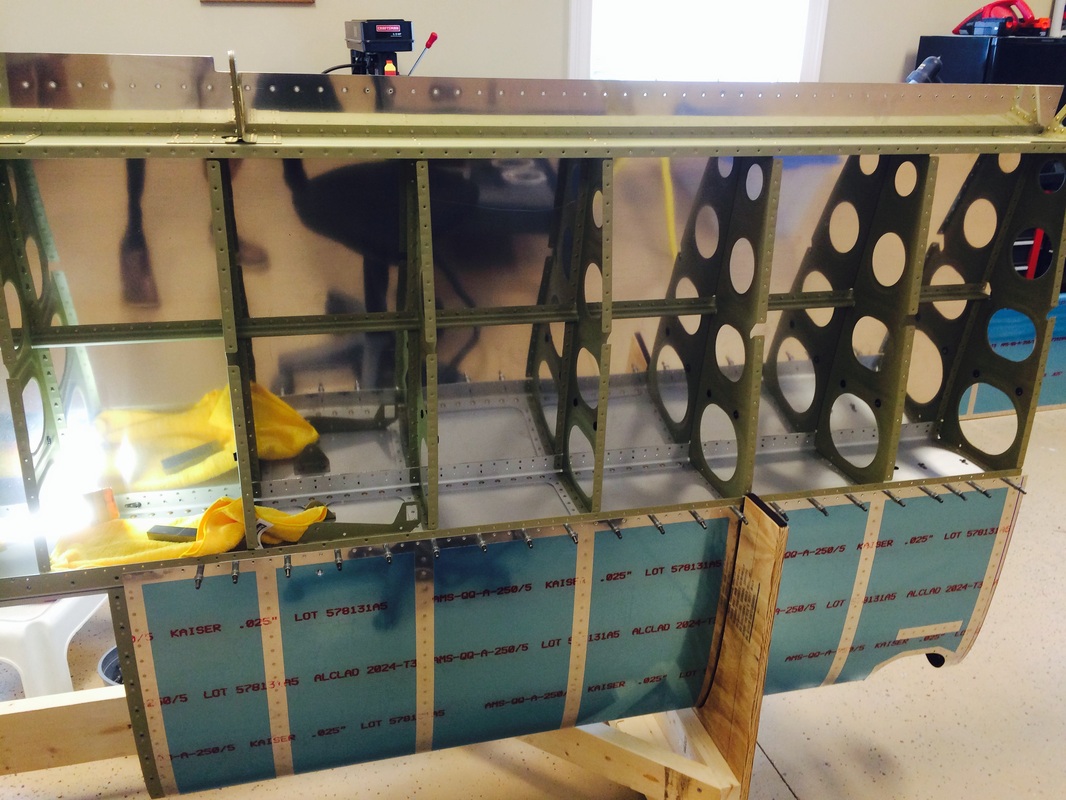

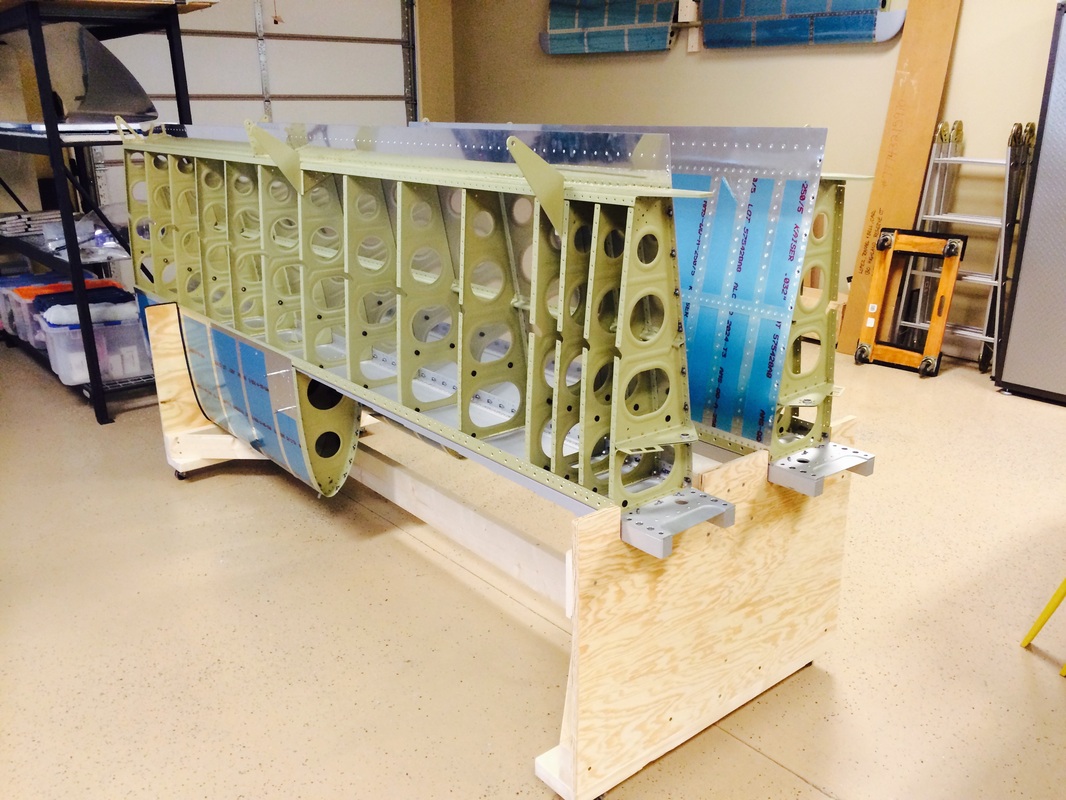

I made the wing caddy last week and patterned it after the one I built for the RV 7A since it worked so well. I put it on locking castors so we can move it around. We used it to rivet the outboard leading edge sections to the main spar. It offers really great access from both sides, but you have to take out the wing you're not riveting.

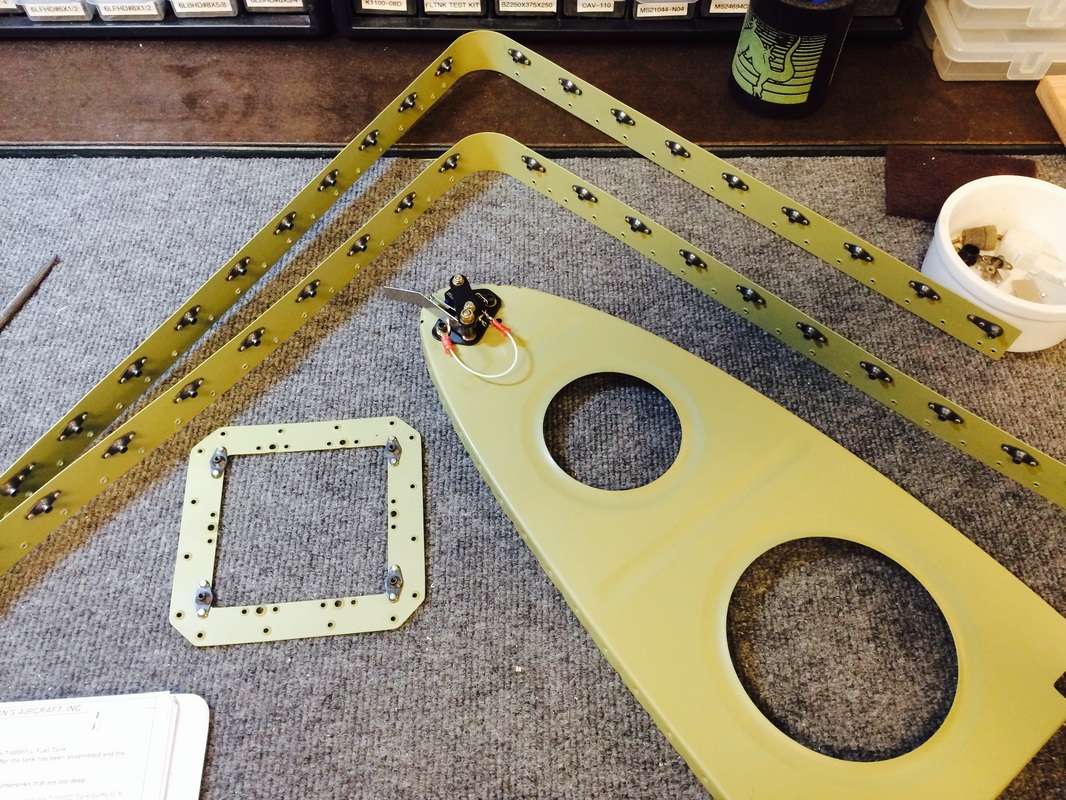

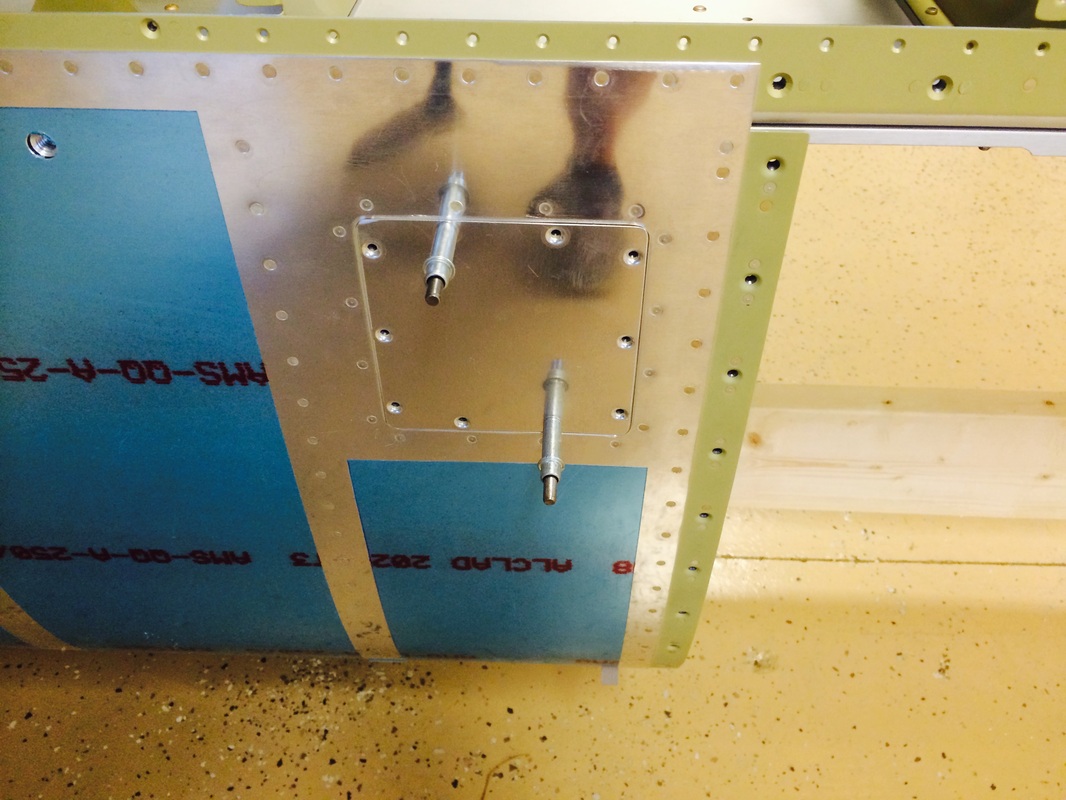

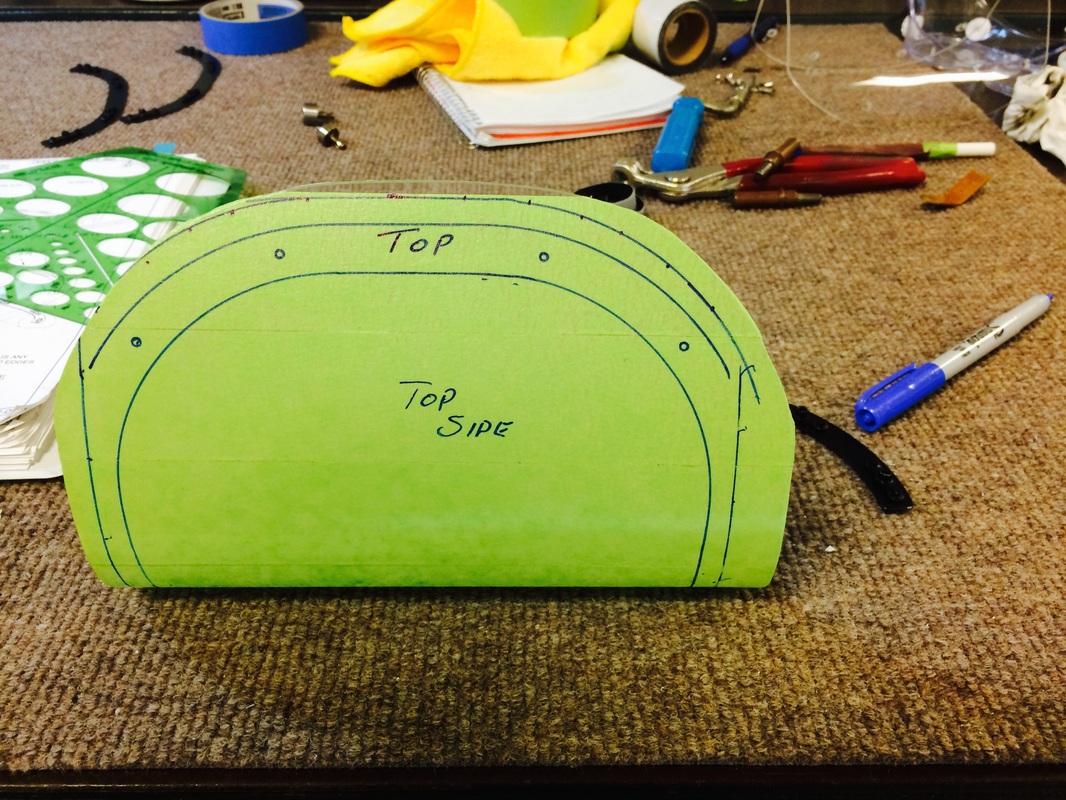

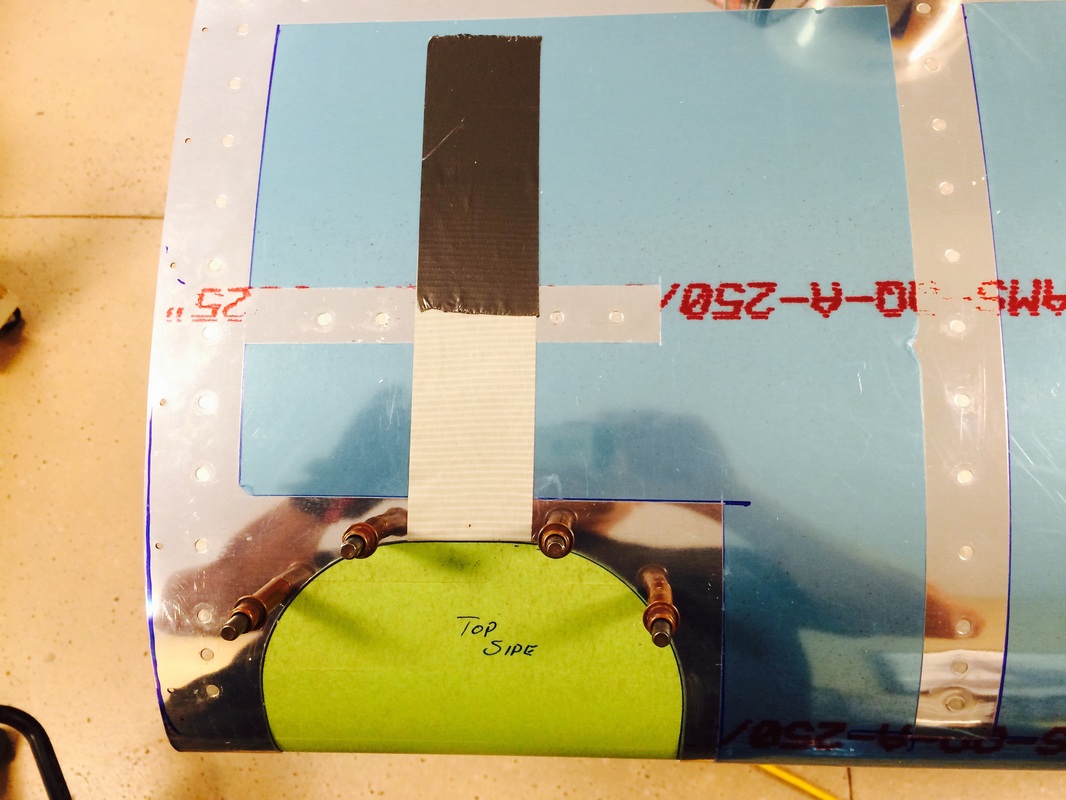

This is where the plans show tape to hold it tight to the skin by pulling out . We double backed the duct tape to pull the tight against the skin and reversed the tape to stick to the wing. Then reach in the lightening hole and push the lens while match drilling the 4 screw holes on the top and bottom. It still will not be tight all around the cutout because the shape of the airfoil does not exactly match the lens shape. Close, but not perfect.

This is one of my favorite tools. Made by Proxxon, it is a very good quality belt sander the get used constantly on the RV. I finished off the plexi edges with this and 240 grit belts. I will also hit the edges with a buffing wheel and some rough to take off the sanding marks. Yes this is more than required, but it only take a few minutes.