Cowling - Section 45

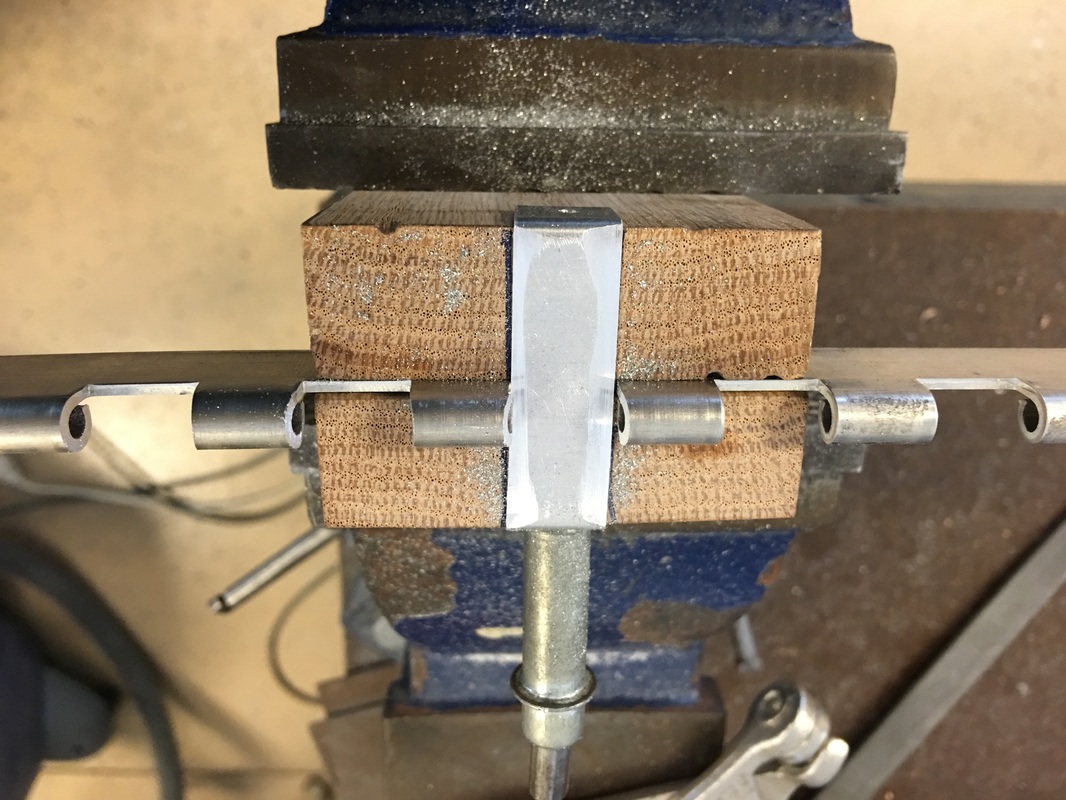

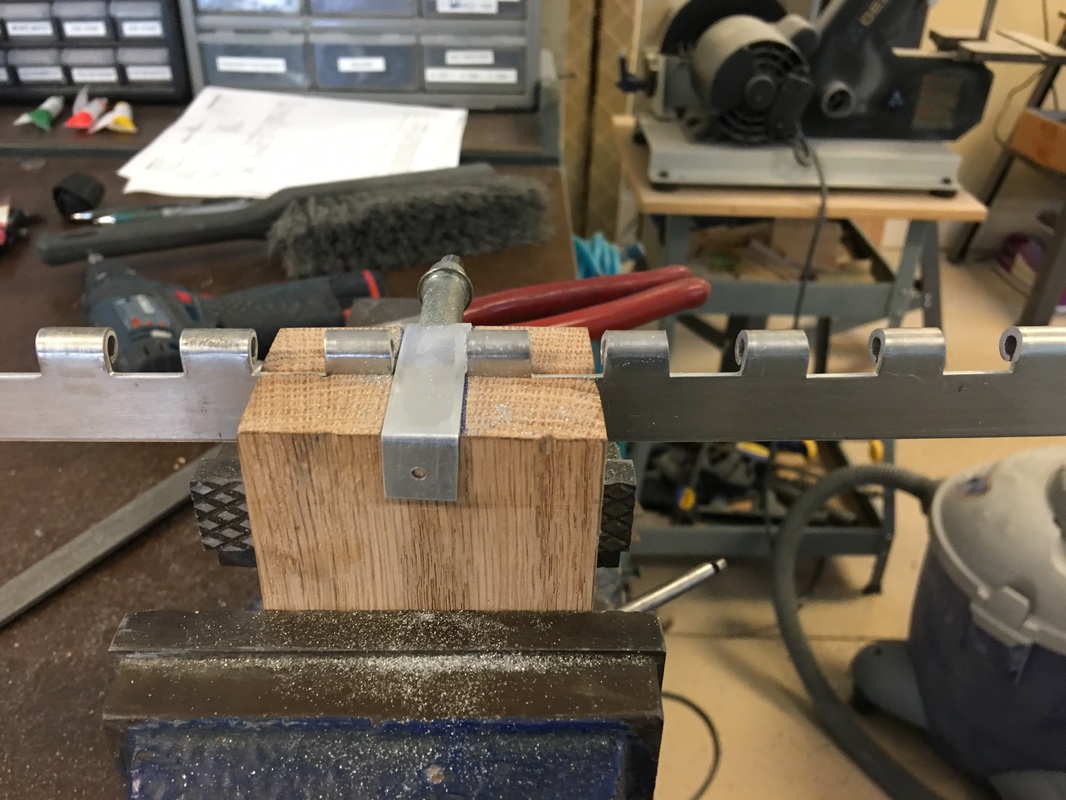

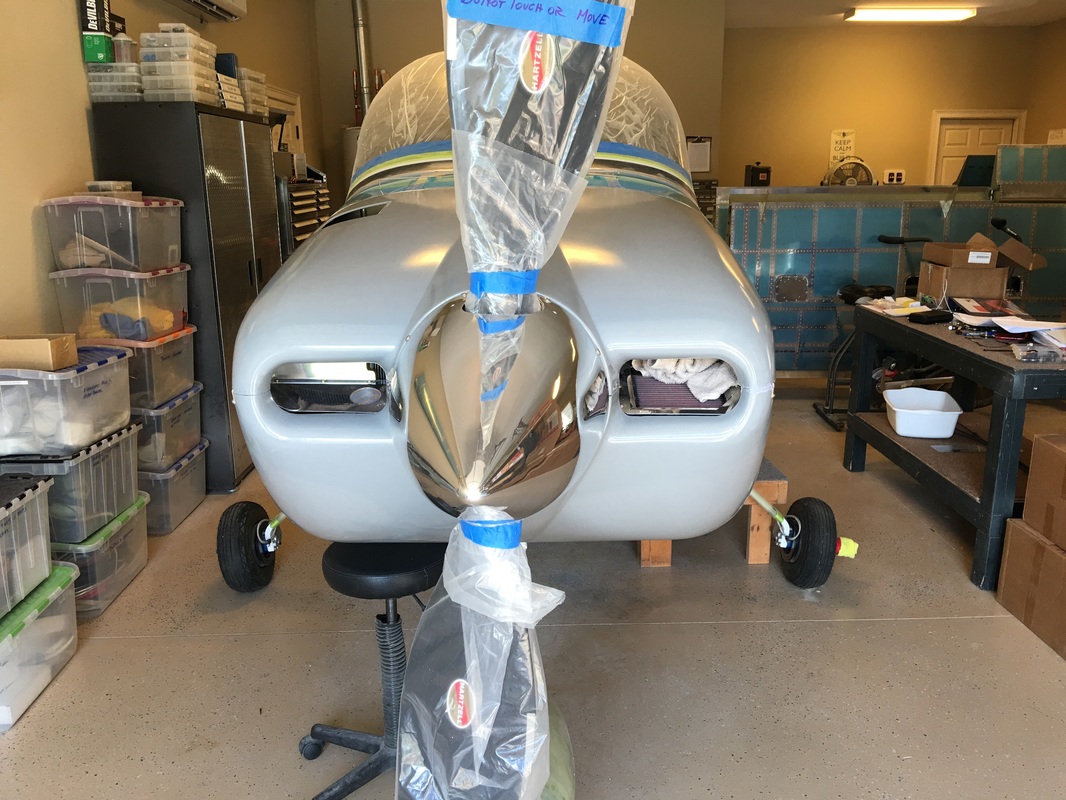

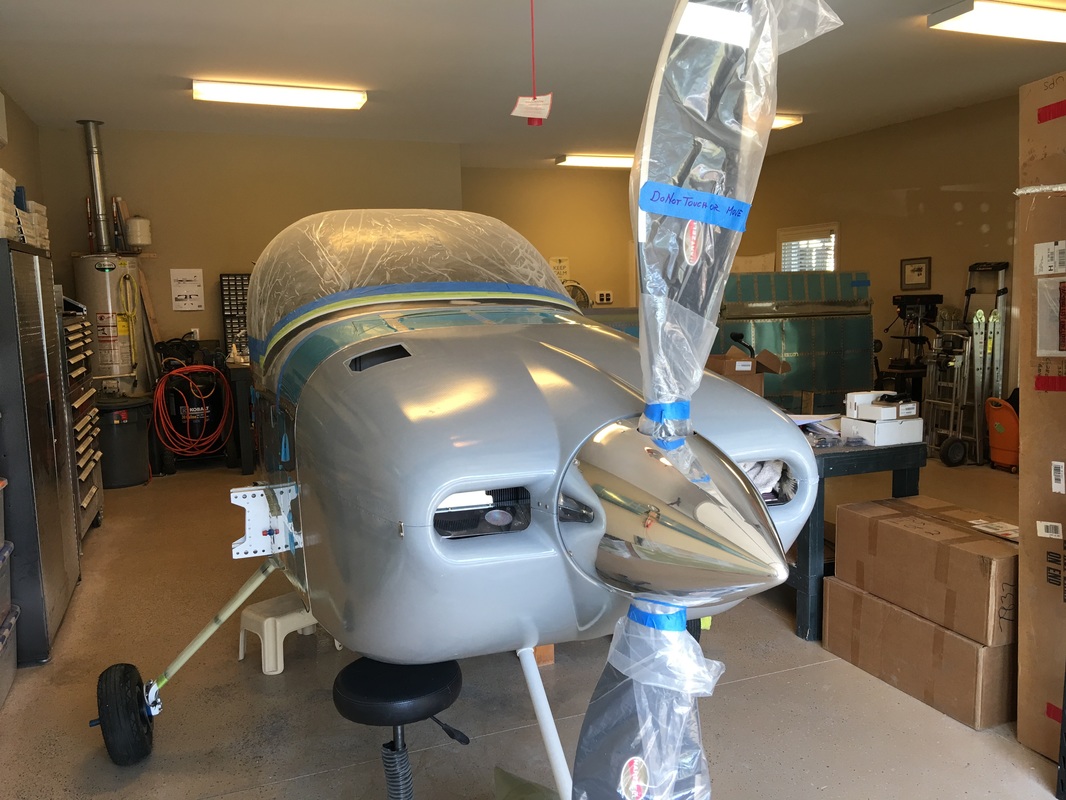

We started the cowling May 12th and I have been remiss in updating the BLOG since there were some issues. As it turns out the Carbon CS Hartzel prop hub is different then the metal hub. The is the case because the blades are wider and they would hit the cowl in full pitch if there wasn't more separation. This has happened, and we were not aware of it when we bought our propeller from Van's with the IO 390. The good news, the cowling will fit, but we needed to ignore the scribe lines. After messing with it for a few days, I don't think the scribe lines for either prop are as close as they should be and I would recommend fitting the cowl the old fashion way shown below. I used a plywood spacer for the separation, then Vans plans using the angle and washer to hold the cowl the right height. After that I clecoed the cowl nose ring to the plywood spacer to hold it in place and then used my home made edge duplicator to make the firewall line. I made it a little big to begin with and then block sanded the edge until it fall in place on the hinges. Follow the plans in getting the nose ring close to final position and the top and bottom fitting together, then sand the rest of the way by hand and a 18" block with 100 grit.

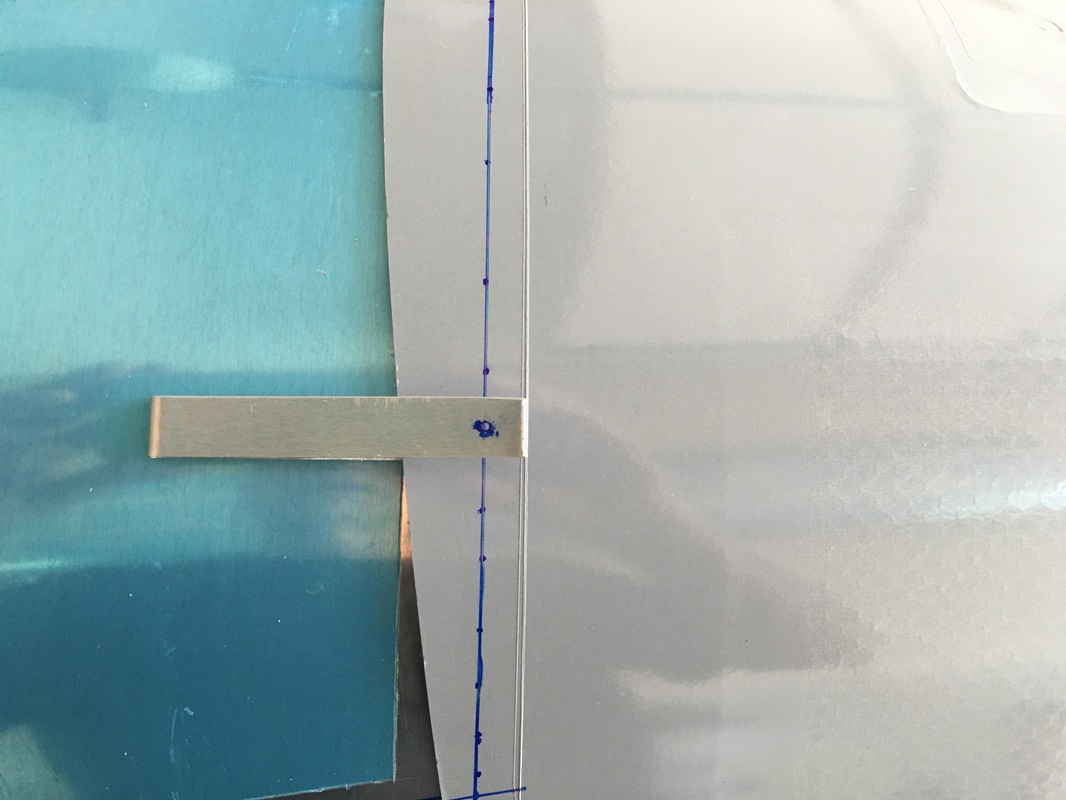

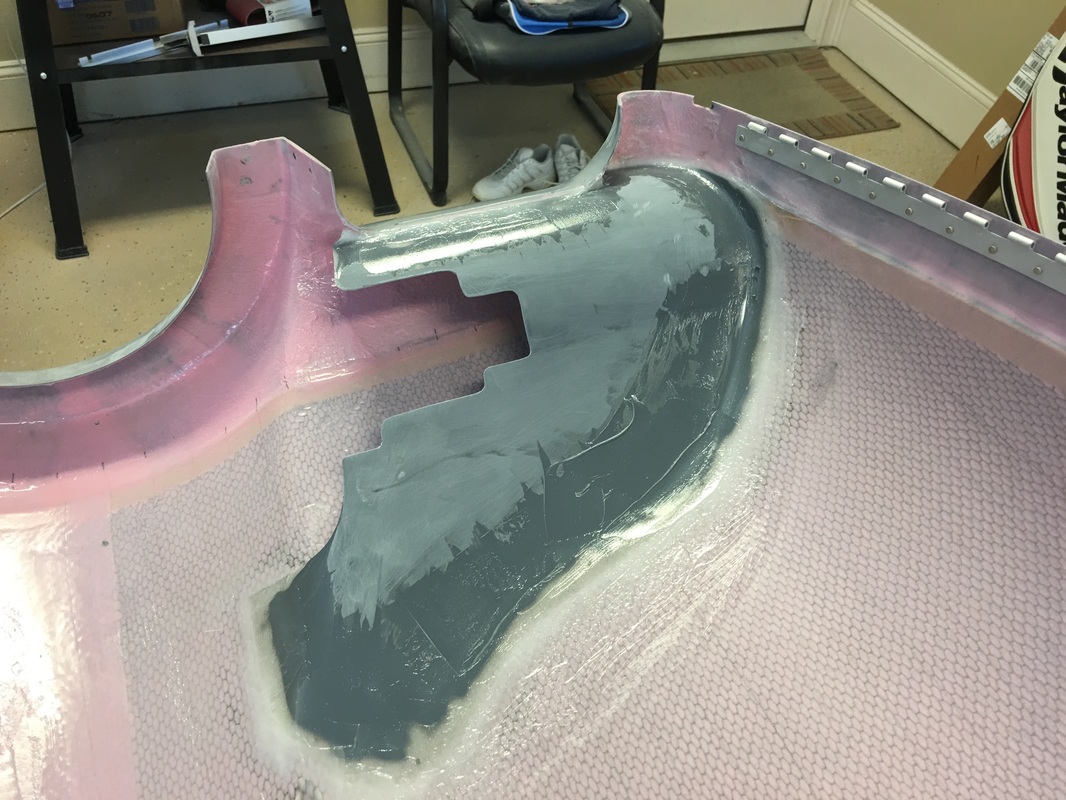

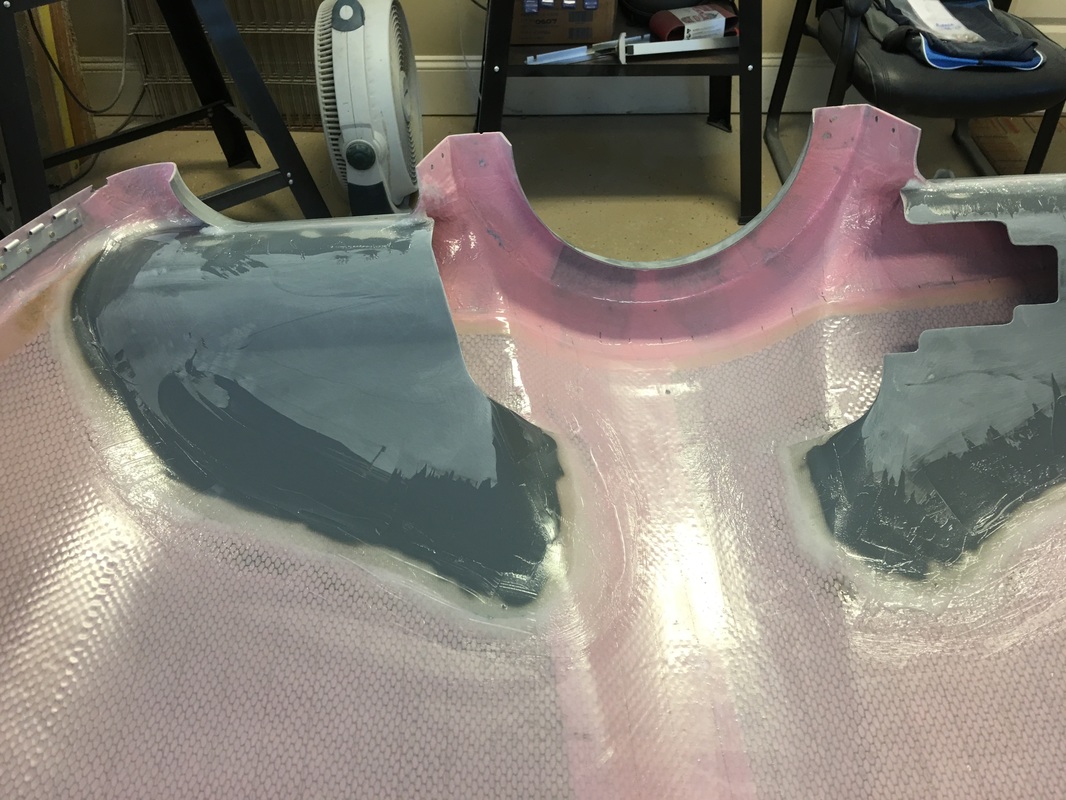

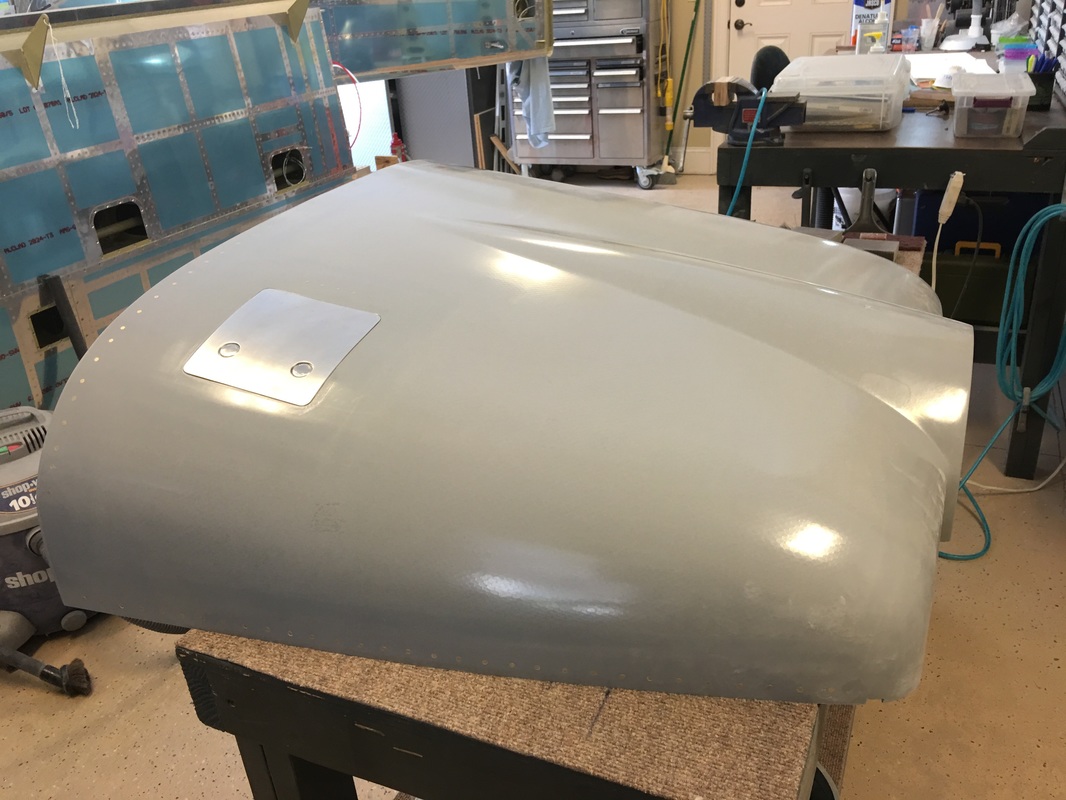

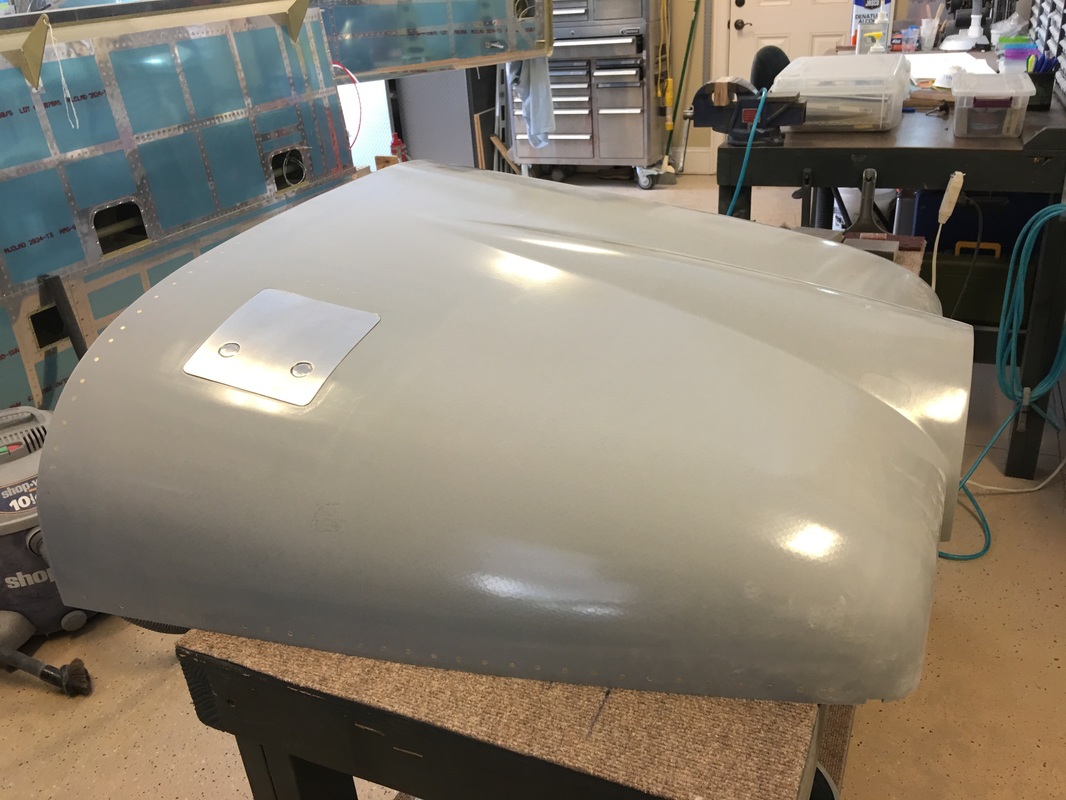

This is one very expensive oil door. First we wanted to use the Hartwell KM 610-64 flush latches. They are hard to find and expensive to the tune of $30 each. Second we wanted to use the very solid and spring loaded Avery hinge, another $42. Last we had to remake the door itself because Vans wanting to make things easy and prepunched the curved .062 aluminum door and I didn't have any hole filler. So we bought some .062 Aluminum from Aircraft Spruce, then took it to a machine shop to have the curve rolled into it. So that added another $45.