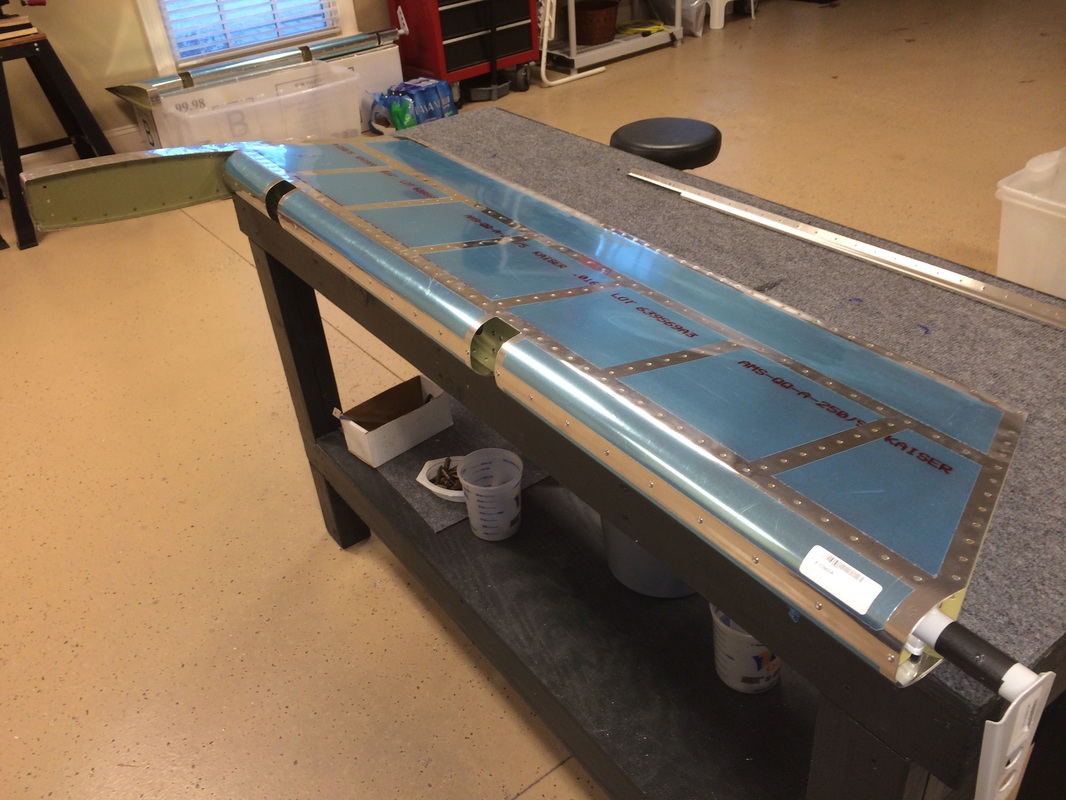

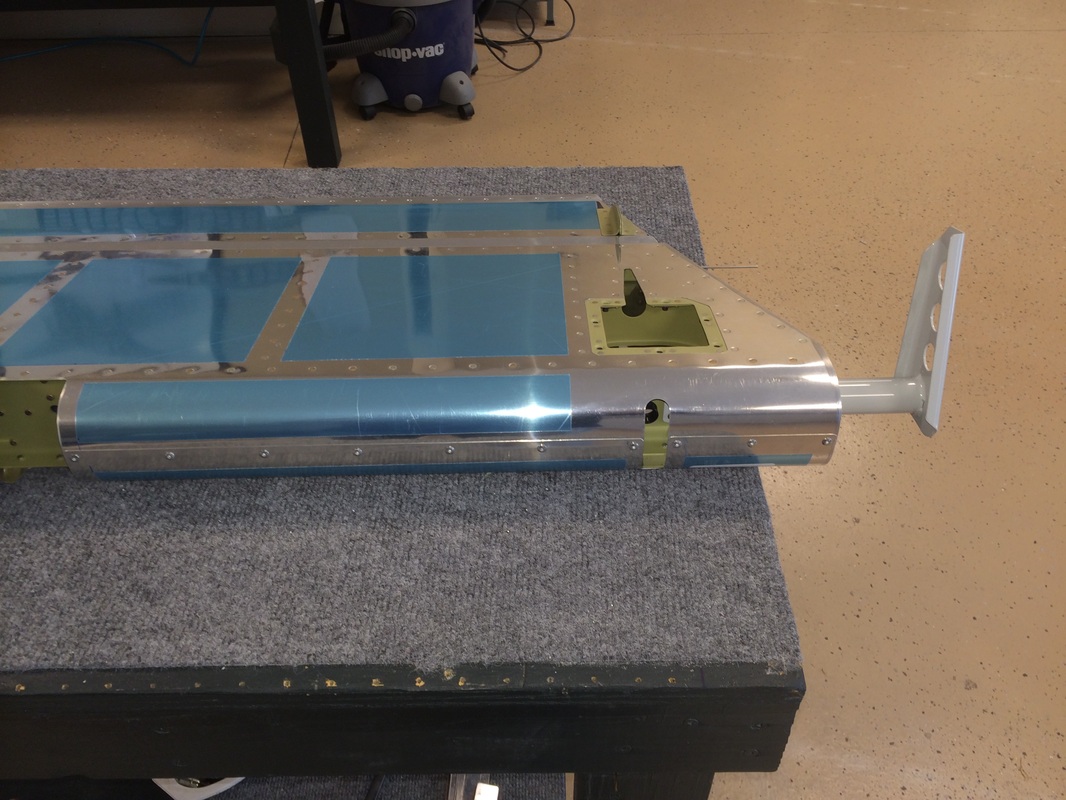

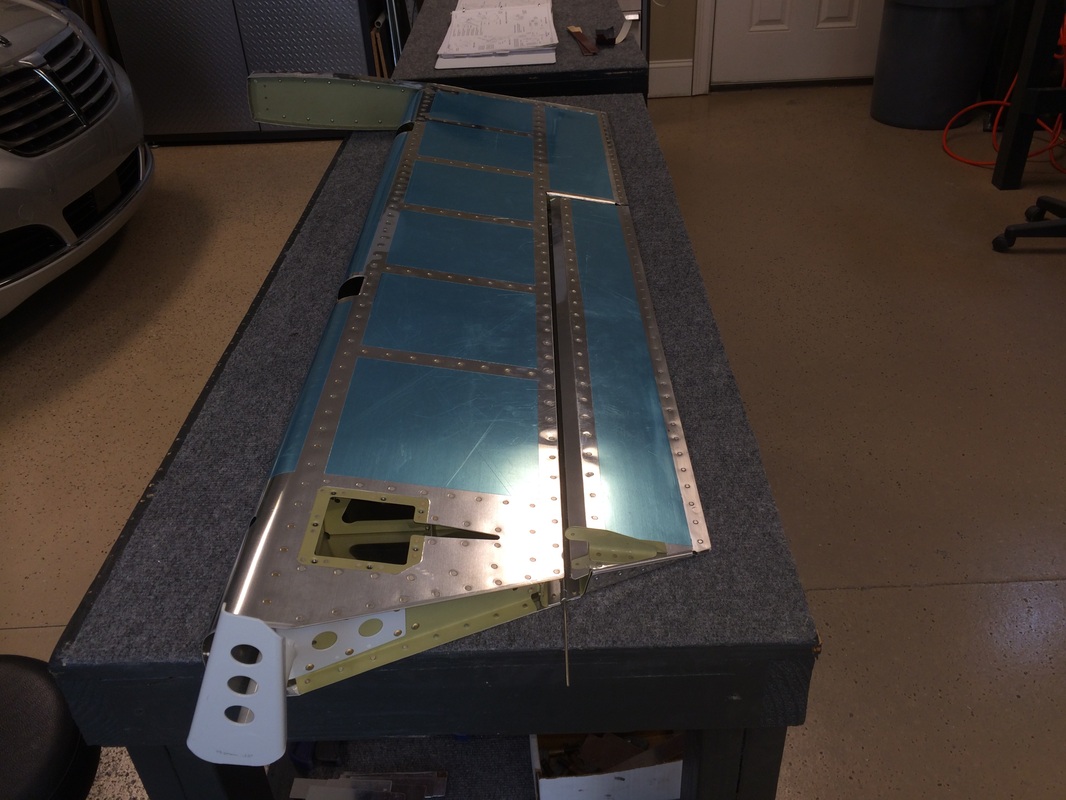

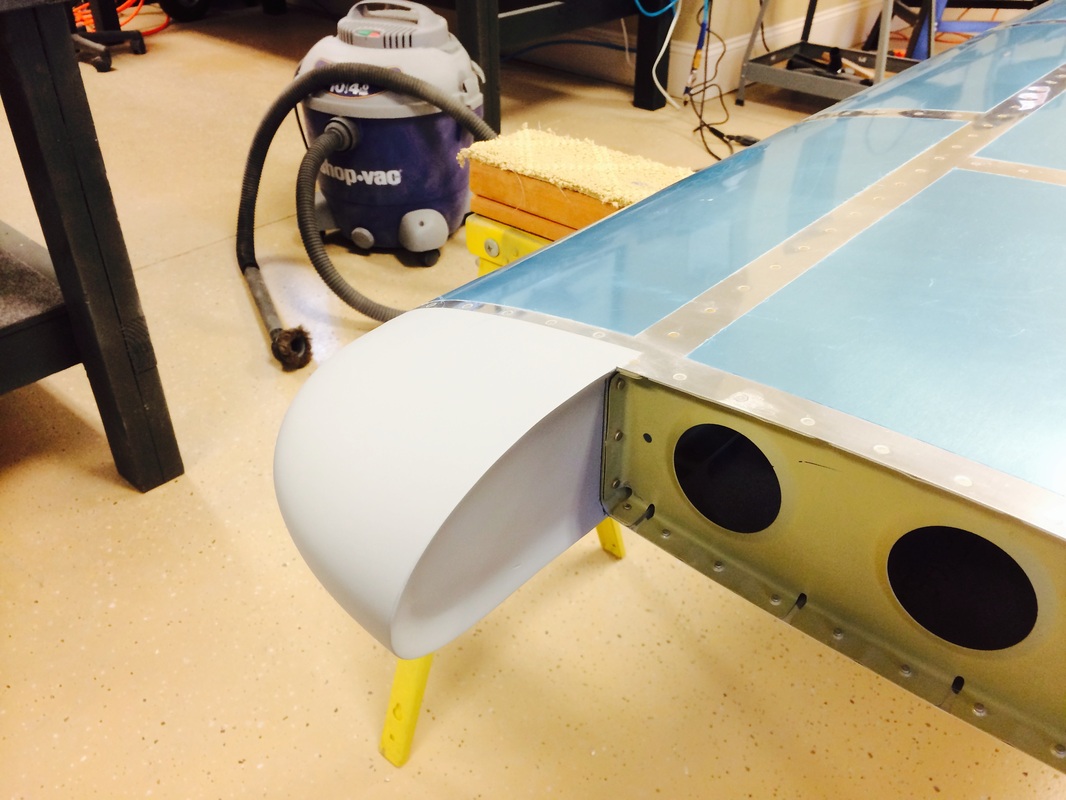

Trouble in Paradise: We were installing the elevators per the manual to drill the horns and noticed a 0.150 inch misalignment in the elevator trailing edge after clamping the balance weight to the stab. We are not sure if the is an issue, but we thought it was best to find out. See note from Rafael and pictures below to Van's

To Van's email support line

We are ready to drill the holes for the elevator push rod. As instructed, we placed the elevators in trail by aligning the forward skins to the horizontal stabilizer. When examining the alignment of the trailing edges, we see a deviation of about 0.17” (as near as I can measure) at the right elevator inboard point.

The procedure we used is as follows:

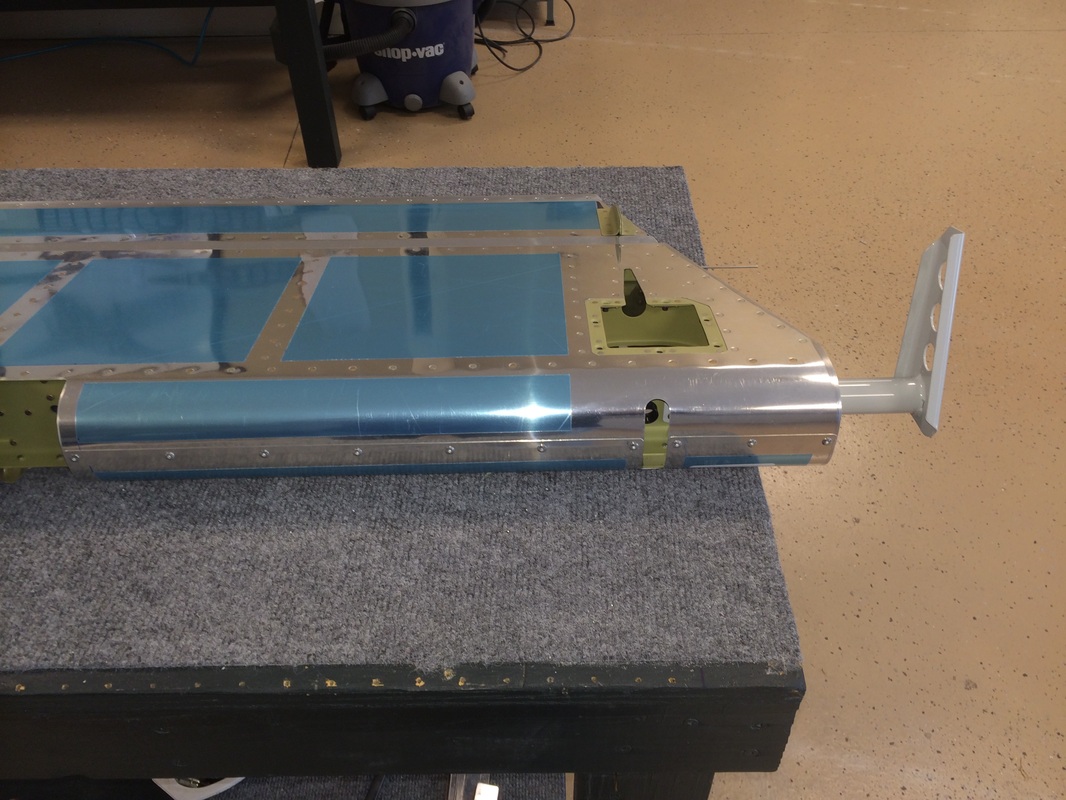

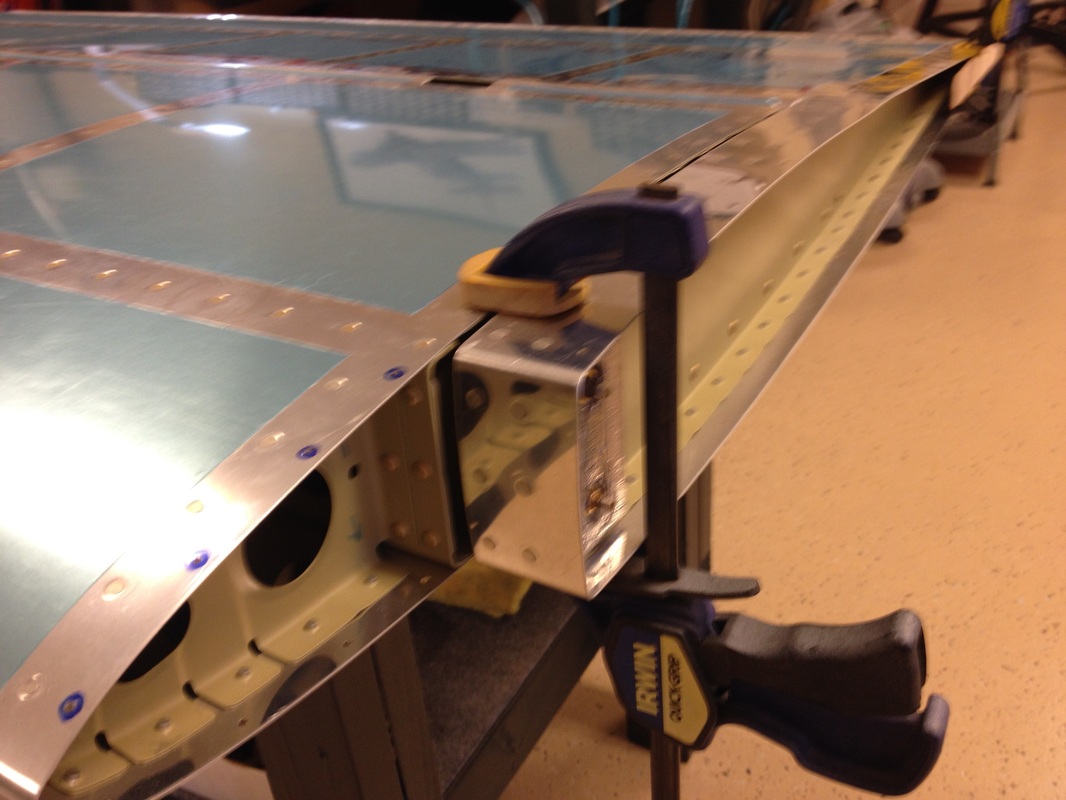

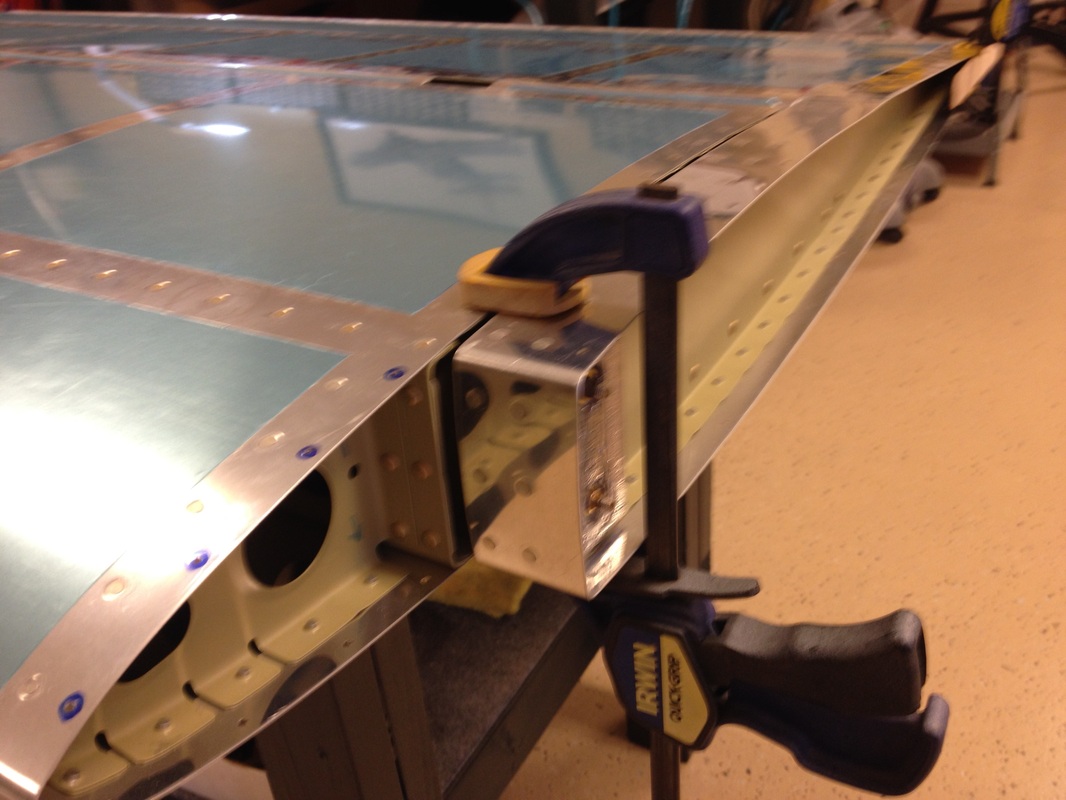

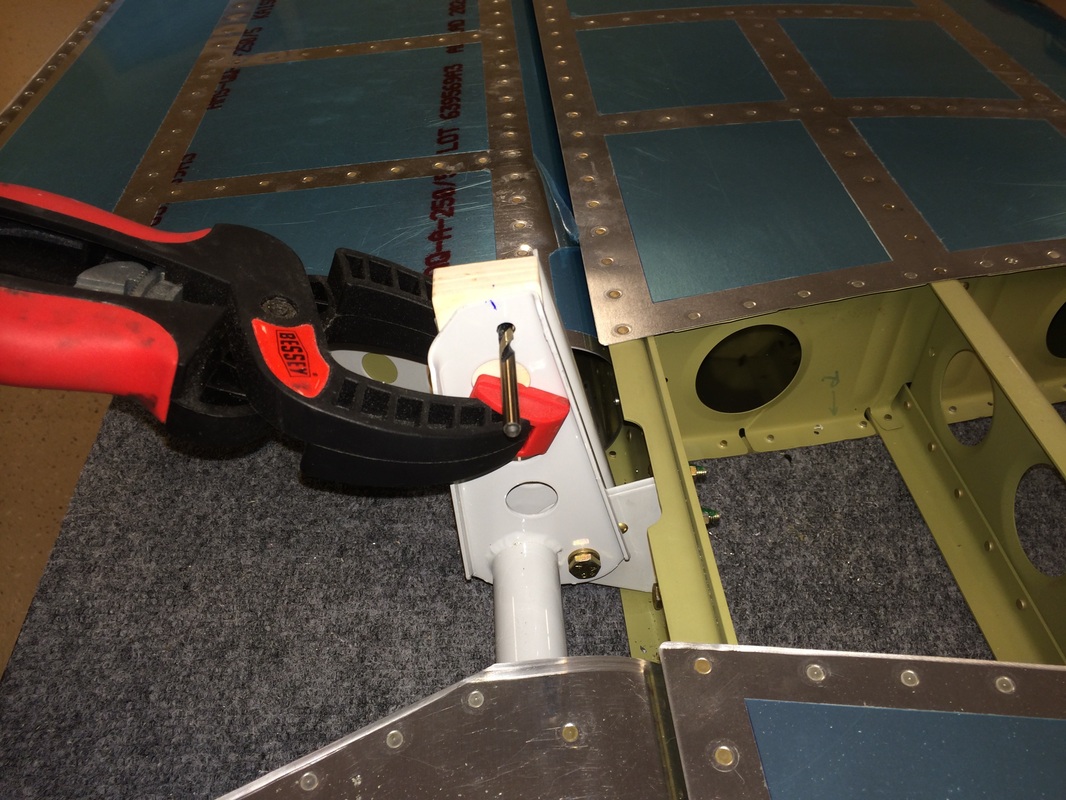

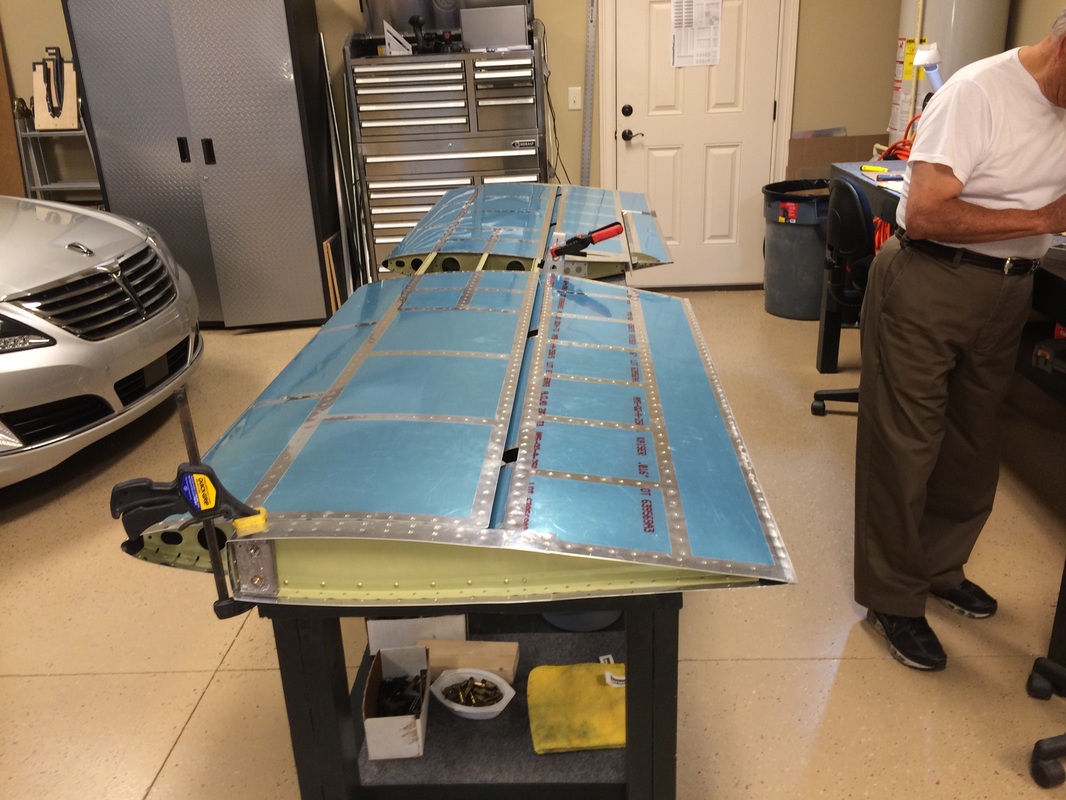

I first clamped the leading edge counterbalance skins on both elevators to the horizontal stabilizer.

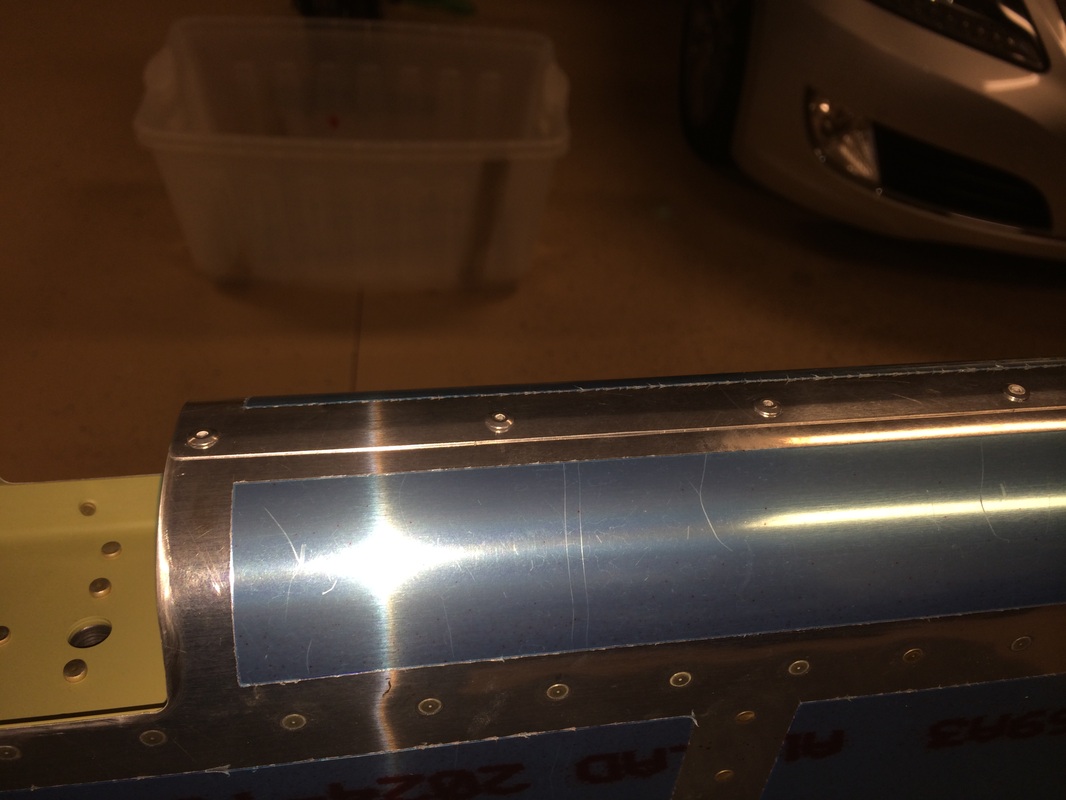

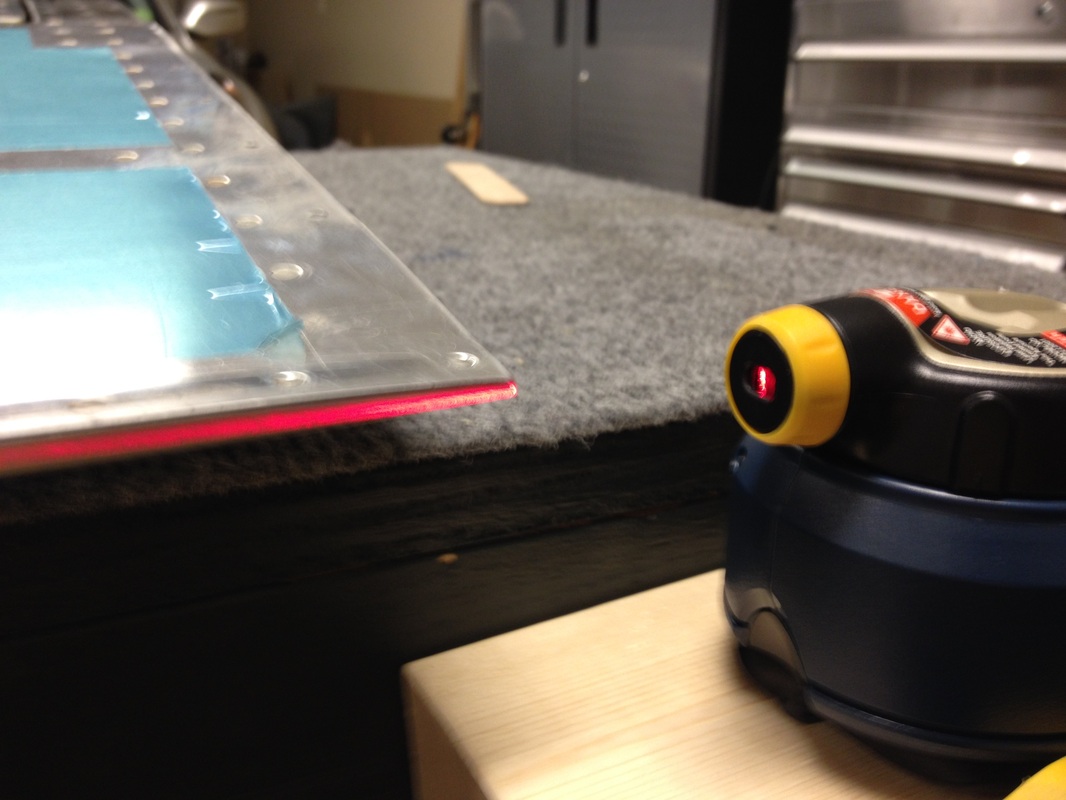

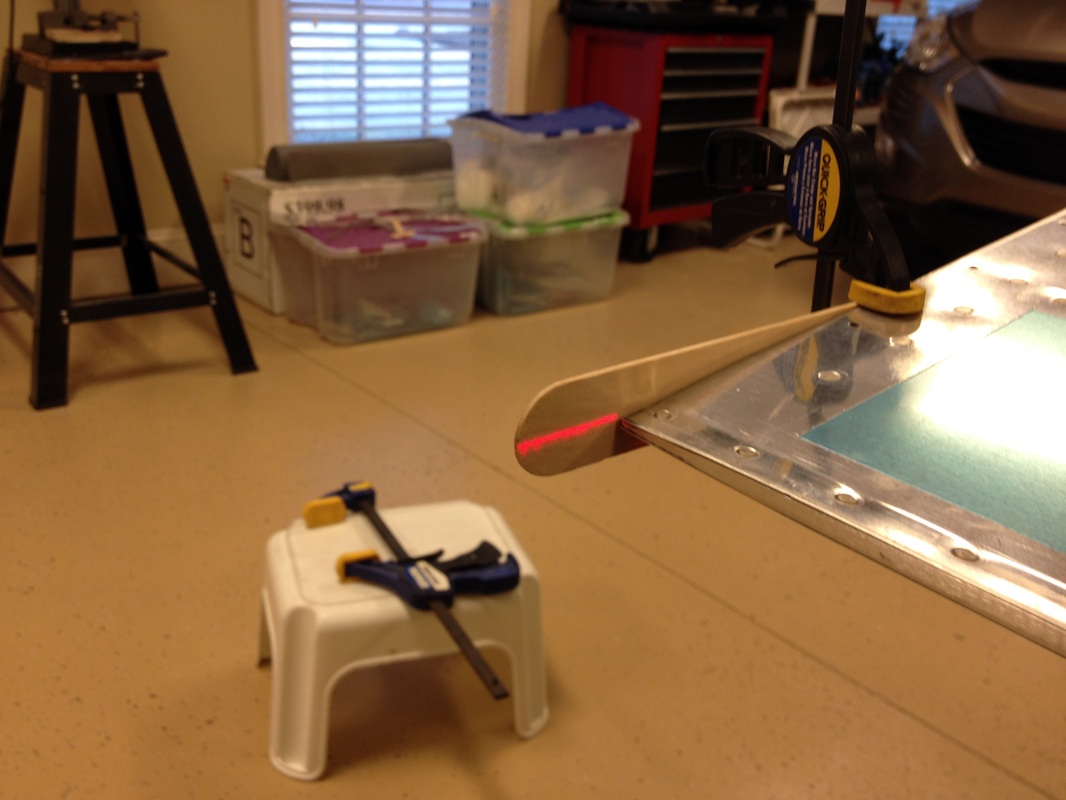

I then set up the laser to be straight between the right and left outboard edge points.

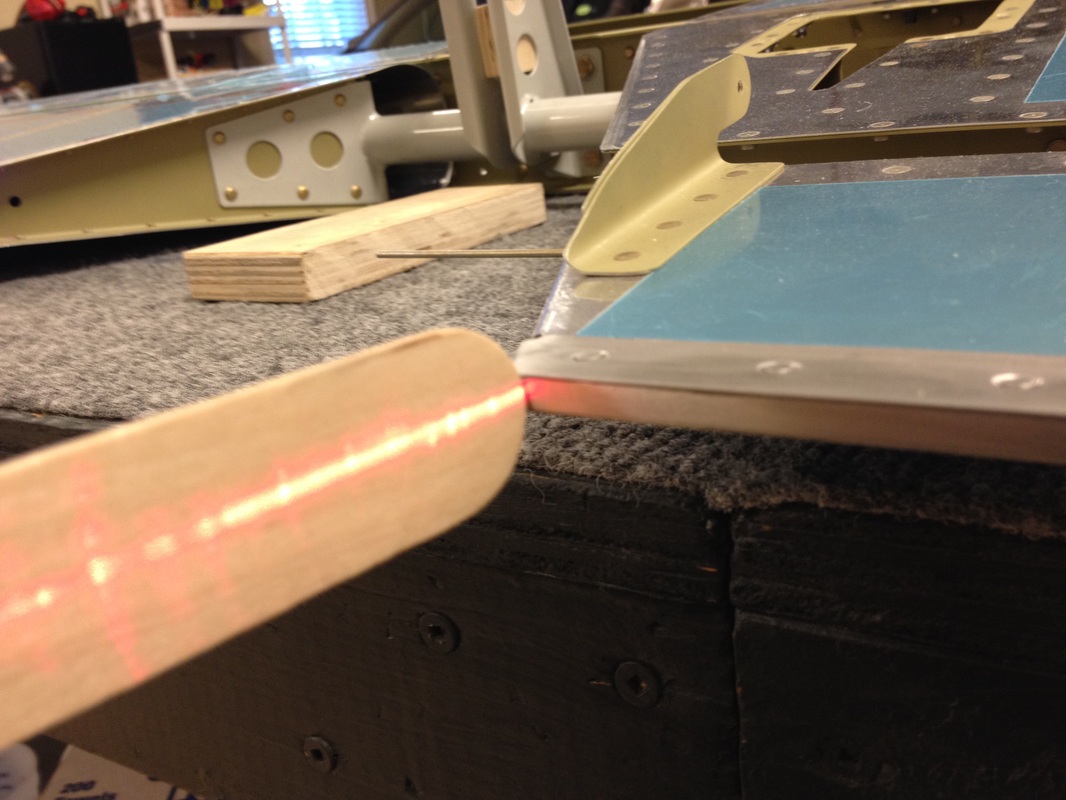

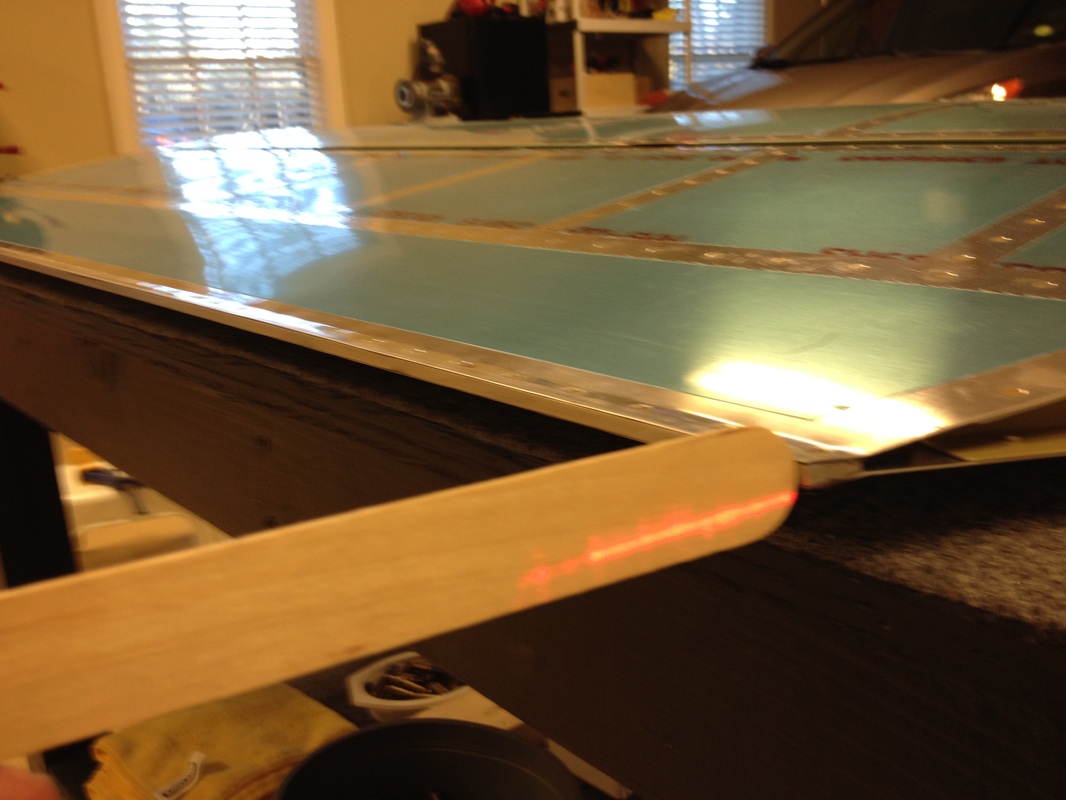

Finally, I took pictures at five points along the trailing edges. As you can see, the maximum deviation occurs at the inboard edge of the right elevator.

1. What do you think the effect of this error will be?

2. Is this going to require extra trim tabs or other corrective action?

3. We are leaning towards aligning the counterbalance skins as opposed to mis-aligning them to minimizing the trailing edge variation. Do you agree?

4. Would you please comment on how typical these results are?

Thanks and best regards,

Rafael

To Van's email support line

We are ready to drill the holes for the elevator push rod. As instructed, we placed the elevators in trail by aligning the forward skins to the horizontal stabilizer. When examining the alignment of the trailing edges, we see a deviation of about 0.17” (as near as I can measure) at the right elevator inboard point.

The procedure we used is as follows:

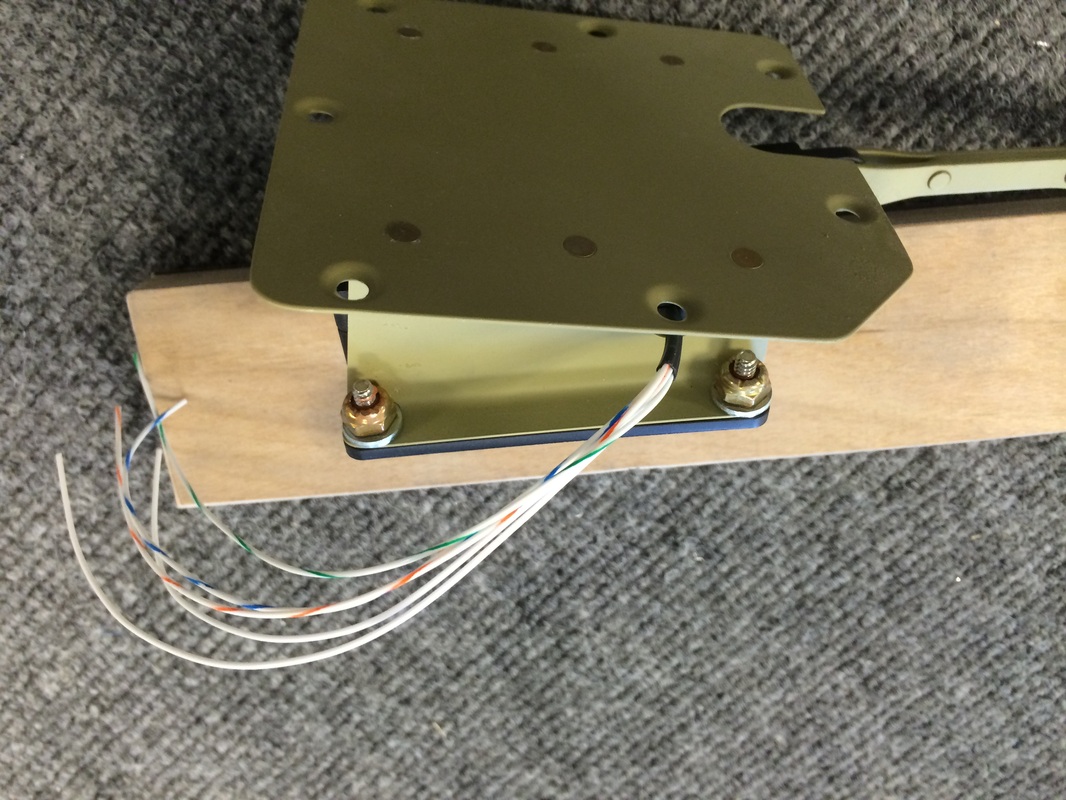

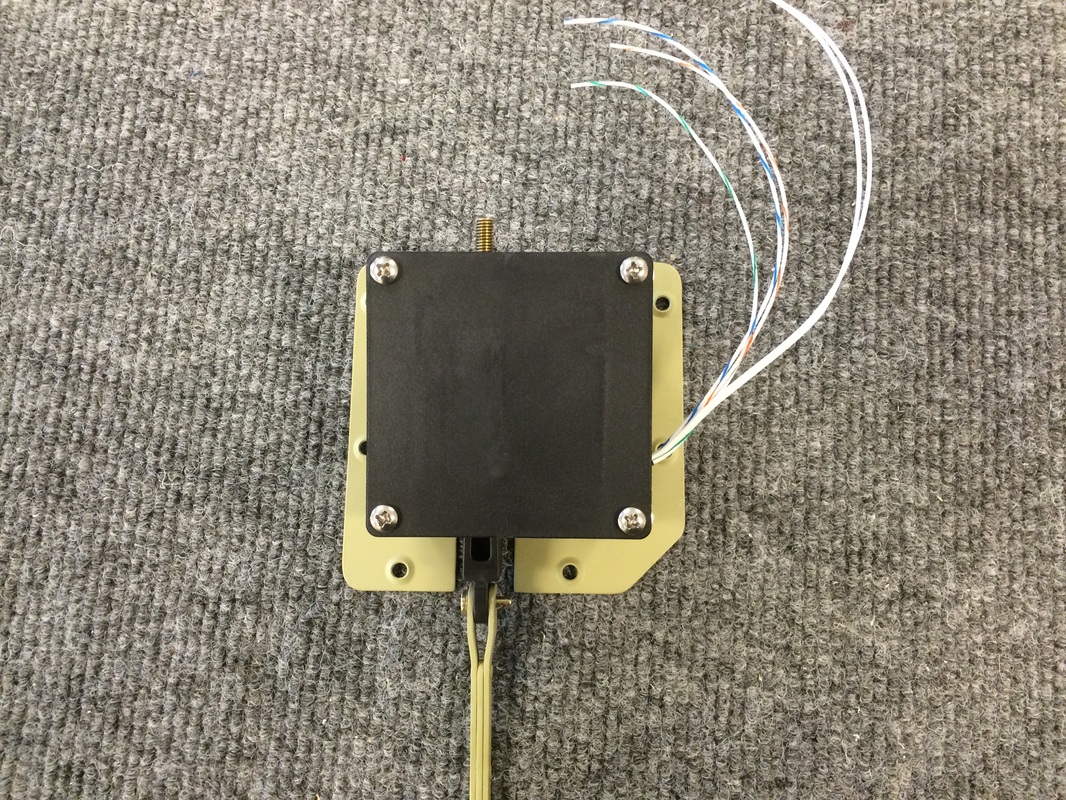

I first clamped the leading edge counterbalance skins on both elevators to the horizontal stabilizer.

I then set up the laser to be straight between the right and left outboard edge points.

Finally, I took pictures at five points along the trailing edges. As you can see, the maximum deviation occurs at the inboard edge of the right elevator.

1. What do you think the effect of this error will be?

2. Is this going to require extra trim tabs or other corrective action?

3. We are leaning towards aligning the counterbalance skins as opposed to mis-aligning them to minimizing the trailing edge variation. Do you agree?

4. Would you please comment on how typical these results are?

Thanks and best regards,

Rafael

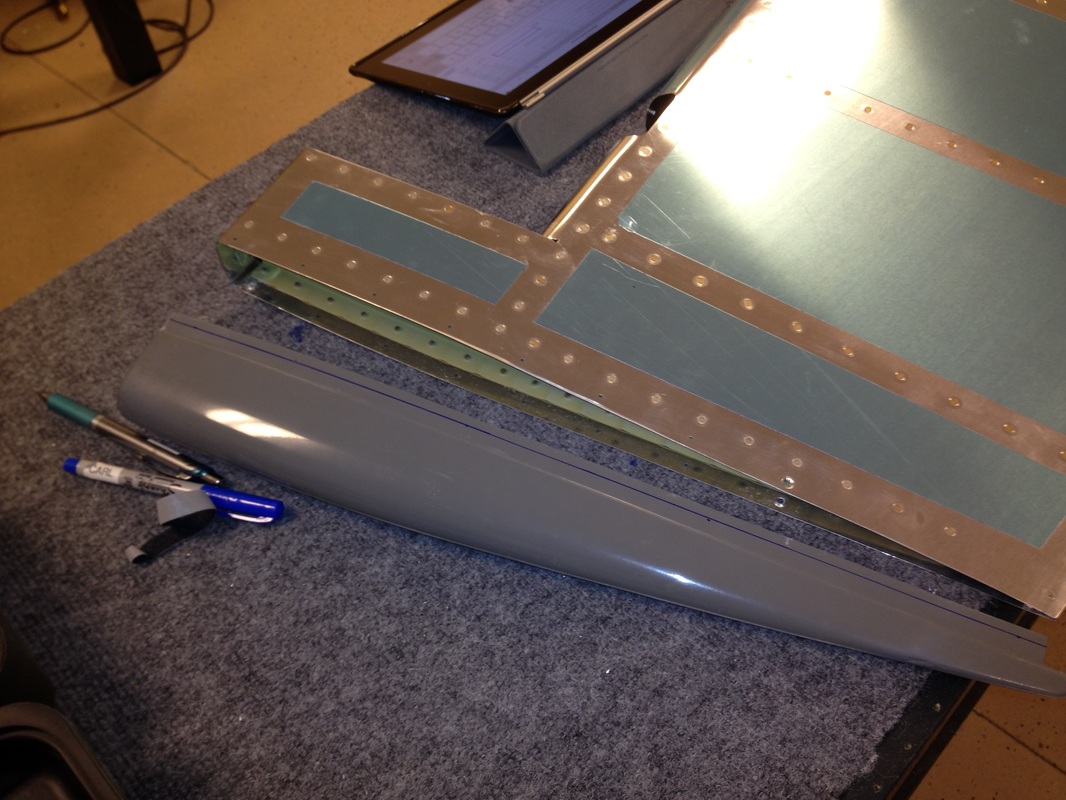

Laser at outside left edge. This may be within tolerances, but we just don't know yet. We did build it on a flat bench, so I'm not quite sure why the inside on the elevator is p over 1/8" unless the rear edge riveting made it move some. The trailing edges are very straight. This makes me think the cumulative punched hole tolerances were enough to allow the deviation from flat. So word back from Van's was the it was within the scope of rounding error. They suggested clamping the trailing edges with boards and then drilling the horn. We massaged it and came close to to eye ball straight.

We used a slight concave surface so the gap looks smaller yet keeps the 1/8" Van's wants in the plans. This also worked out well on the RV 7. I looked at Van's RV 7 at Sun & Fun and they also looked great and was probably a whole lot less trouble than what we did. Oh well, it is the journey not the destination, right?